Fixed focal length C-mount industrial lenses

1/1.8″ vs 2/3″ Lens Sensor Size Compatibility

02/06/2026

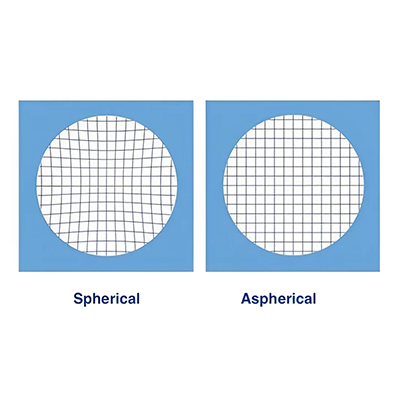

Spherical vs Aspherical Lenses: Balancing image quality and manufacturing cost

02/08/2026Table of Contents

Key Takeaways

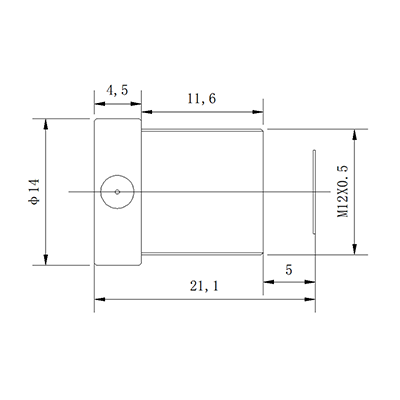

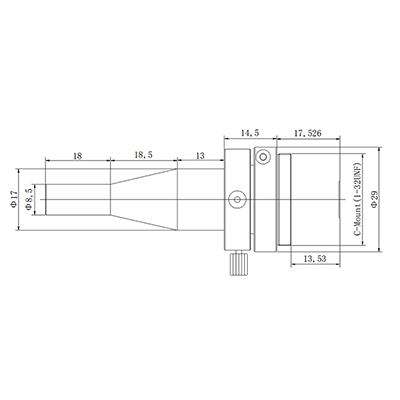

- C-Mount Lenses: Industry-standard threaded lenses with a 17.526mm flange focal length (B.F.L.), universally compatible with industrial cameras and machine vision systems.

- Fixed Focal Lenses: Prime lenses with non-adjustable focal lengths, delivering stable image quality, durable construction, and cost-effectiveness for industrial use.

- Core Advantages: Broad compatibility, low distortion, easy operation, and rugged design—ideal for 24/7 industrial automation environments.

- Selection Essentials: Match sensor size, calculate focal length/field of view (F.O.V.), and prioritize resolution/aperture based on your specific application.

- TOWIN Series Highlights: 10–20MP high resolution, ultra-wide-angle options (up to 180° F.O.V.), and ultra-low distortion (<1% for select models) for precision inspection tasks.

Introduction

In the era of industrial automation, machine vision systems are the backbone of quality control and operational efficiency—and the lens is the system’s “critical visual core.” Fixed focal C-Mount industrial lenses have become indispensable across electronics manufacturing, automotive component inspection, logistics sorting, and more, thanks to their standardized interface, reliable optical performance, and cost-effectiveness.

As a trusted manufacturer specializing in industrial optics, TOWIN has engineered a full range of fixed focal C-Mount lenses tailored to diverse industrial needs. This guide breaks down everything you need to know—from foundational definitions and key parameters to step-by-step selection, real-world applications, and product advantages—helping you make fast, informed decisions to maximize your machine vision system’s performance.

Foundational Knowledge: What Are Fixed Focal C-Mount Industrial Lenses?

1.1 What Is a C-Mount Lens?

A C-Mount lens is a standardized threaded optical lens with industry-unified technical specifications:

- Fixed flange focal length (B.F.L.): 17.526mm (distance between the lens mount and image sensor), ensuring compatibility across brands.

- Thread specification: 1-inch diameter with 32 threads per inch (1″-32 UN-2A), enabling secure, tool-free installation.

- Compact design: Ideal for space-constrained industrial setups, compatible with industrial cameras, surveillance devices, and machine vision terminals.

- Versatile optical adaptation: Works with cameras of varying resolutions and sensor sizes, from entry-level to professional-grade imaging.

1.2 What Is a Fixed Focal Industrial Lens?

A fixed focal (prime) industrial lens is designed for stable imaging in industrial environments, with a non-adjustable focal length:

- Optimized image quality: No focal length drift—delivers sharp, low-distortion results at a fixed magnification.

- Durable construction: Fewer moving parts reduce wear and maintenance costs, supporting 24/7 continuous operation.

- Superior light transmission: Optical design optimized for specific focal lengths, outperforming zoom lenses in light gathering under the same aperture.

- Cost-efficiency: Simplified manufacturing (no complex zoom mechanisms) makes them ideal for high-volume industrial applications.

1.3 Key Differences Between C-Mount and CS-Mount Interfaces (Critical for Selection)

Interface compatibility is make-or-break for lens performance. Here’s how C-Mount and CS-Mount—two common industrial interfaces—compare:

| Comparison Factor | C-Mount Interface | CS-Mount Interface |

| Flange Focal Length | 17.526mm (industry standard) | 12.5mm (compact design) |

| Compatible Devices | C-Mount industrial cameras, machine vision terminals | Native CS-Mount cameras; requires a 5mm spacer for C-Mount devices |

| Typical Applications | Industrial automation inspection, precision measurement, professional machine vision | Compact surveillance, lightweight imaging terminals, space-constrained basic inspection |

| Selection Risk | No sensor damage when installed correctly; stable compatibility | Risk of sensor scratches and misfocus if used with C-Mount cameras without a spacer |

Core Parameters: What to Look for When Selecting a Fixed Focal C-Mount Lens

A lens’s performance is defined by its key parameters—matching these to your application is critical to avoiding imaging issues. Here’s a breakdown of what matters most:

| Core Parameter | Definition | Selection Tips |

| Image Format/Sensor Size | Maximum sensor area the lens can cover (e.g., 1/1.8″, 2/3″, 1.1″, 1″) | Lens format ≥ camera sensor size to avoid vignetting/blur; e.g., 2/3″ sensor needs ≥2/3″ lens. |

| Focal Length | Distance between lens optical center and image sensor (industrial specs: 2.2mm, 4.5mm, 6mm, 8mm, 12.5mm) | Inverse to F.O.V.: Shorter (2.2/4.5mm) = ultra-wide F.O.V. (large-area); longer (8/12.5mm) = narrow F.O.V. (long-distance magnification). |

| Field of View (F.O.V.) | Captured area (measured H/V/D) | Calculate by target size and working distance; e.g., 1m-wide object at 2m needs ≥30° diagonal F.O.V. |

| Resolution | Maximum effective pixel support (5MP, 10MP, 20MP mainstream) | 5-10MP for general defect detection; 10-20MP for high-precision tasks (e.g., micro-component measurement). |

| Aperture (F-Number) | Light transmission range (e.g., F1.4~16, F1.8~16, F2.8~16) | Small F-numbers (F1.4/F1.8) for low-light; large (F8~16) for deep depth of field (multi-layer inspection). |

| TV Distortion | Geometric distortion (industrial lenses: typically <2.5%) | <1% for measurement tasks; <2.5% sufficient for general imaging. |

| Minimum Object Distance (M.O.D.) | Closest sharp focus distance (common: 5mm, 0.1m) | 5mm for close-range inspection (e.g., PCB solder joints); 0.1m+ for long-distance monitoring. |

| Iris Control Type | Manual Iris or Auto Iris | Manual: Cost-effective, precise for stable lighting; Auto: Adapts to variable lighting (e.g., outdoor sorting). |

Core Benefits: Why Fixed Focal C-Mount Lenses Dominate Industrial Applications

Compared to zoom lenses or non-standard interface lenses, fixed focal C-Mount industrial lenses offer unmatched advantages for industrial use:

1. Standardized Interface Design: Compatibility and Flexibility Combined

- C-Mount Standardization: The 25.4 mm (1-inch) threaded locking interface ensures secure connections between lenses and industrial cameras or imaging systems, guaranteeing universal compatibility.

- Cross-Brand Interoperability: Lenses from different manufacturers seamlessly integrate with industrial cameras via C-mount, reducing system integration costs and eliminating waste from mismatched interfaces.

- Rapid Deployment and Maintenance: In automated production lines or security surveillance, users can swiftly swap lenses with varying focal lengths without complex adjustments, significantly cutting maintenance time. For example, in forestry fire monitoring projects, C-mount lenses reduced single-point installation time from 4 hours to under 90 minutes.

2. High-Precision Imaging: Meeting Industrial Inspection Demands

- Superior Optical Performance: Fixed focal lenses employ advanced optical designs to deliver high resolution, low distortion, and high contrast, ensuring sharp image details.

- Ultra-Low Distortion Control: In precision inspection fields (e.g., semiconductors, electronic components), lenses with distortion rates below 0.1% minimize measurement errors, enhancing accuracy.

- Large Aperture Design: Some lenses (e.g., TECHSPEC® C-Series) feature wide apertures (e.g., f/1.4), capturing clear images even in low-light conditions, adapting to complex industrial lighting environments.

3. Stability and Durability: Withstanding Harsh Industrial Conditions

- Robust Construction: Metal housings provide shockproof, dustproof, and waterproof capabilities, enduring extreme temperatures, humidity, and vibrations for long-term reliability.

- Strong Anti-Interference Performance: In scenarios with production line vibrations or rapid object movement, mechanical locking mechanisms reduce image blur, ensuring consistent imaging quality.

- Long Lifespan and Low Maintenance: The absence of motorized components reduces failure points, lowering maintenance costs and suitability for 24/7 industrial operations.

4. Cost-Effectiveness: Balancing Performance and Budget

- Affordable Pricing: Compared to motorized zoom lenses, fixed focal lenses have simpler structures, lower costs, and further price reductions through bulk purchases.

- Multi-Lens Strategy: Users can deploy multiple fixed focal lenses tailored to specific needs (e.g., wide-angle surveillance and macro inspection) at a lower total cost than a single high-end zoom lens.

- Long-Term ROI: High durability and low failure rates minimize equipment replacement frequency, reducing lifecycle costs.

5. Specialized Scenario Optimization: Addressing Industrial Pain Points

- Automated Production Lines: Fixed focal lenses monitor component positioning, dimensions, and defects in real time during assembly and quality checks, ensuring process compliance.

- Precision Inspection: In medical devices or semiconductor manufacturing, their high-precision imaging supports micron-level defect detection, meeting stringent industry standards.

- Security Surveillance: For border control or traffic management, fixed focal lenses combine with wide-angle or telephoto lenses for full-scene coverage, reducing missed detections.

6. Complementarity with Motorized Zoom Lenses

- Scenario-Specific Adaptability: Fixed focal lenses excel in applications with constant focal length requirements (e.g., fixed-station inspections), while motorized zoom lenses suit dynamic scenarios needing flexible adjustments (e.g., mobile surveillance).

- Technological Synergy: In complex industrial systems, fixed focal lenses handle routine inspections, and zoom lenses address anomalies, improving overall system efficiency.

low distortion wide angle C-mount industrial lens

Step-by-Step Selection Process: How to Choose the Right Lens

Industrial applications vary widely—follow these 7 steps to select the perfect fixed focal C-Mount lens and avoid costly mistakes:

1: Confirm Camera Sensor Size & Match Image Format

Start by identifying your camera’s sensor size (e.g., 1/1.8″, 2/3″). The lens’s image format must equal or exceed the sensor size:

- Camera sensor = 1/1.8″ → Compatible lens formats: 1/1.8″, 2/3″, 1.1″

- Camera sensor = 2/3″ → Avoid 1/1.8″ lenses (risk of vignetting or cropped images)

2: Calculate Focal Length & F.O.V. Based on Your Application

Use this formula to find the required focal length (or adjust F.O.V. for existing lens options):

Focal Length (mm) = (Sensor Size (mm) × Working Distance (mm)) / Target Object Size (mm)

Example: Using a 2/3″ sensor (8.8mm horizontal size) to inspect a 100mm-wide part at 500mm working distance:

Focal Length = (8.8 × 500) / 100 = 44mm → Choose a lens with a similar focal length (e.g., 8mm, 12.5mm) or adjust F.O.V. accordingly.

3: Select Resolution Based on Inspection Precision

- General Inspection (e.g., part presence checks, surface scratches): 5MP–10MP

- High-Precision Tasks (e.g., micro-component measurement, print clarity checks): 10MP–20MP

4: Choose Aperture Range for Lighting Conditions

- Low-Light/Backlit Environments: Wide aperture (F1.4~F2.8) for better light gathering

- Bright/Deep Depth of Field Needs: Narrow aperture (F8~F16) for sharp foreground/background

5: Control Distortion for Your Task Type

- Geometric Measurement (e.g., part dimensions, gap checks): Ultra-low distortion (<1%) → TOWIN C0823028M10 (<1%), C0802316M5 (<0.75%)

- Visual Inspection (e.g., surface defects, color checks): Distortion <2.5% → TOWIN C0611018M20 (<2.5%)

6: Match M.O.D. to Working Distance

- Close-Range Inspection (<0.1m): M.O.D. ≤0.1m → TOWIN C02211828M10 (M.O.D. = 5mm)

- Long-Distance Inspection (>1m): M.O.D. ≥0.1m → Ensure clear focus at your operating distance

7: Select Iris Type for Lighting Stability

- Stable Lighting: Manual Iris (cost-effective, locked parameters for consistency)

- Variable Lighting: Auto Iris (real-time exposure adjustment to avoid detection errors)

2.2mm wide-angle lens

Real-World Applications: Where Fixed Focal C-Mount Lenses Excel

Fixed focal C-Mount lenses are versatile enough to power critical tasks across industries. Here’s how they’re used in key sectors:

1. Electronics Manufacturing

- Use Cases: PCB solder joint inspection, electronic component dimension measurement, chip pin defect detection

- Recommended Lenses: High-resolution (10MP–20MP) + ultra-low distortion models → TOWIN C0823028M10 (10MP), C0611018M20 (20MP)

- Key Requirement: Capture tiny defects to ensure assembly precision

2. Automotive Components

- Use Cases: Automotive screw tightening checks, component surface scratch detection, assembly gap measurement

- Recommended Lenses: Medium-to-long focal lengths (8mm–12.5mm) + deep depth of field → TOWIN C1201014M5 (12.5mm)

- Key Requirement: Long-distance inspection of large components with sharp detail

3. Logistics & Packaging

- Use Cases: Barcode/QR code scanning, package dimension measurement, label alignment checks

- Recommended Lenses: Ultra-wide angles (2.2mm–4.5mm) + fast focusing → TOWIN C02211828M10 (2.2mm, 180° F.O.V.), C04511828M5 (4.5mm)

- Key Requirement: Wide coverage for high-speed sorting lines

4. Medical & Life Sciences

- Use Cases: Medical device component inspection, lab sample imaging, microscope auxiliary imaging

- Recommended Lenses: High-resolution (10MP+) + low distortion → TOWIN C0802316M5 (5MP, <0.75% distortion)

- Key Requirement: Distortion-free imaging for medical-grade quality control

5. Industrial Security & Monitoring

- Use Cases: Workshop panoramic surveillance, hazard zone monitoring, equipment status checks

- Recommended Lenses: Ultra-wide angles (2.2mm–6mm) + rugged design → TOWIN C0611018M20 (6mm, 118° F.O.V.)

- Key Requirement: Large F.O.V. to cover wide areas in harsh industrial environments

TOWIN Fixed Focal C-Mount Lens Series: Key Advantages

TOWIN’s fixed focal C-Mount lenses are engineered to solve industrial pain points, with standout features:

1. Full-Spectrum Compatibility

- Focal lengths: 2.2mm (ultra-wide) to 12.5mm (standard)

- Sensor support: 1/1.8″, 2/3″, 1″, 1.1″

- Resolutions: 5MP, 10MP, 20MP → Balances cost and performance for every use case

2. Ultra-Low Distortion for Precision

- Select models (e.g., C0802316M5) offer distortion as low as 0.75%

- Most models <1% distortion—outperforming industry averages for measurement accuracy

3. Industrial-Grade Durability

- Metal housings + sealed construction: Dustproof, vibration-resistant, and temperature-tolerant (-10℃~60℃)

- Non-slip manual controls: Precise adjustment for frequent use without wear

4. Plug-and-Play Integration

- Strict adherence to C-Mount standards (17.526mm B.F.L., 1″-32 UN-2A threads)

- Compatible with Sony ICX674ALG, IMX178, e2v EV76C570, and other mainstream sensors

- Standardized mounting holes: No custom brackets required—fast installation

Recommended Models: TOWIN’s Top Fixed Focal C-Mount Lenses

Choose the perfect lens for your application with these high-performance options:

| Model | Key Specifications | Ideal For |

| C1201014M5 | 1″ sensor, 12.5mm focal length, 5MP, F1.4~16 aperture, <1.6% distortion, 15.6mm B.F.L. | General industrial imaging, medium-distance inspection, low-light environments |

| C0823028M10 | 2/3″ sensor, 8mm focal length, 10MP, F2.8~16 aperture, <1% distortion, 11.5mm B.F.L. | Precision inspection, low-distortion measurement, electronic component checks |

| C0802316M5 | 2/3″ sensor, 8mm focal length, 5MP, F1.6~C aperture, <0.75% distortion, 0.1m M.O.D. | Ultra-low distortion imaging, barcode scanning, biometrics |

| C0611018M20 | 1.1″ sensor, 6mm focal length, 20MP, F1.8~16 aperture, 118° diagonal F.O.V., <2.5% distortion | High-resolution large-area inspection, workshop panoramic monitoring |

| C04511828M5 | 1/1.8″ sensor, 4.5mm focal length, 5MP, F2.8~16 aperture, 82° horizontal F.O.V., 0.1m M.O.D. | Compact wide-angle applications, logistics sorting, small part inspection |

| C02211828M10 | 1/1.8″ sensor, 2.2mm focal length, 10MP, F2.8~16 aperture, 180° F.O.V., 5mm M.O.D. | Panoramic imaging, ultra-wide surveillance, close-range wide-angle inspection |

FAQs

Q1: Can C-Mount and CS-Mount lenses be used interchangeably?

A: Yes—with caveats:

- C-Mount lens → CS-Mount camera: Requires a 5mm spacer to compensate for B.F.L. differences (without it, focus fails and sensors may be damaged).

- CS-Mount lens → C-Mount camera: Not recommended—shorter B.F.L. prevents proper imaging.

Q2: Fixed focal vs. zoom lenses—Which is better for industrial use?

A: Prioritize fixed focal lenses for: Batch production inspection, stable lighting, and fixed task requirements (e.g., single-part inspection)—they’re more stable, cost-effective, and durable.Choose zoom lenses only if: You need to inspect multiple part sizes (frequent focal length adjustments) or require flexible F.O.V.—but expect higher costs and maintenance.

Q3: Does higher resolution always mean better image quality?

A: No—resolution must match your camera:

- 5MP camera + 20MP lens: Image quality equals 5MP (wasted lens capability).

- 20MP camera + 5MP lens: Insufficient detail for high-precision tasks.

- Rule of thumb: Lens resolution ≥ camera resolution, aligned with your inspection needs.

Q4: Is a shorter minimum object distance (M.O.D.) always better?

A: It depends on your working distance:

- Close-range inspection (<0.1m): Shorter M.O.D. (e.g., 5mm) enables macro imaging.

- Long-distance inspection (>1m): Short M.O.D. adds no value—choose a lens matched to your operating distance.

Q5: How do I ensure TOWIN lenses are compatible with my camera?

A: TOWIN lenses adhere strictly to C-Mount standards:

- 17.526mm B.F.L. and 1″-32 UN-2A threads.

- Compatible with mainstream sensors (Sony, e2v, etc.).

- Free compatibility testing available—contact our technical team to verify your camera model.

Conclusion

Fixed focal C-Mount industrial lenses are the backbone of high-performance machine vision systems—their compatibility, stability, and cost-effectiveness directly impact industrial automation precision and efficiency. With this guide’s foundational knowledge, step-by-step selection process, and application insights, you’re equipped to choose the perfect lens for your needs.

TOWIN’s fixed focal C-Mount series—with ultra-low distortion, full-resolution coverage, and rugged industrial design—delivers reliable performance across electronics, automotive, logistics, and more. Whether you need ultra-wide panoramic imaging or high-precision measurement, TOWIN has a tailored solution.