Smart agriculture multispectral imaging lenses

Athermalized lens design for outdoor environments

02/04/2026Table of Contents

id=”toc-1″

Key Takeaways

- What it is: Multispectral imaging lenses capture multiple light bands to analyze vegetation health, critical for smart agriculture.

- Core tech: Relies on light-splitting technologies (filters, gratings, interferometers) to isolate target spectral bands.

- Workflow: Light collection → Spectral splitting → Signal conversion → Data output for agricultural analysis.

- Agri applications: Crop growth monitoring, pest/disease early warning, fertilizer/water management, yield prediction.

- TOWIN advantage: Professional customization, full product range, fast delivery, and agriculture-specific lens designs.

- Why choose TOWIN: 15+ years of optical manufacturing, M12/C/CS-mount options, IR-corrected & low-distortion features.

- FAQs: Covers lens selection, customization, delivery time, and after-sales support.

1. Introduction

Traditional agriculture relies on manual experience, leading to inefficiencies like over-fertilization or delayed pest detection. With the rise of smart agriculture, multispectral imaging lenses have become a game-changer—they capture invisible light bands (e.g., near-infrared) to quantify vegetation health indicators (e.g., chlorophyll content, water status) objectively.

As a professional optical lens supplier since 2008, TOWIN designs and manufactures multispectral imaging lenses tailored for smart agriculture. Our lenses integrate advanced light-splitting tech, compact sizes (e.g., M12 mount), and durable materials, supporting both small-scale single-plant monitoring and large-area farm surveys (up to 10,000 mu/hour).

2. Technical Principles of Multispectral Imaging Lenses

Multispectral imaging lenses differ from ordinary lenses by their ability to split and capture specific light bands. The core lies in spectral splitting technologies, which isolate wavelengths critical for agricultural analysis (400-1000 nm, including visible and near-infrared).

2.1 Main Spectral Splitting Technologies

| Technology Type | Working Principle | Advantages for Smart Agriculture | TOWIN Application |

| Linear Gradient Filter | Gradient coating changes central wavelength; matches detector rows for fast imaging | Lightweight, no slit, high SNR | M12/S-Mount multispectral lenses |

| Grating Spectroscopy | Periodic grooves diffract light; linear wavelength distribution | High spectral resolution (≤1 nm) | C-Mount industrial-grade lenses |

| Michelson Interferometry | Two light beams create interference; Fourier transform to get spectrum | Ultra-high resolution, wavelength-independent | Custom high-precision agricultural lenses |

2.2 Key Optical Features for Agriculture

- IR Correction: Reduces color shift in day/night monitoring (critical for 24/7 crop health tracking).

- Multi-Coating: Increases light transmittance (≥92%) to avoid underexposure in low-light conditions.

- Low Distortion: ≤0.1% distortion ensures accurate spatial mapping of farmland.

3. Working Principle of Multispectral Imaging Lenses

As the core component of a multispectral imaging system, the multispectral imaging lens operates based on two core mechanisms: spectral separation and synchronous/time-sharing imaging. Through special optical design, it decomposes wide-band light into multiple discrete narrow bands and images them separately, thereby capturing the characteristic information of the target in different spectral dimensions and breaking through the perception limit of the human eye’s visible light (380-780nm).

3.1 Core Working Process

The operation of a multispectral imaging lens follows four key steps:

- Light Collection StageThe lens collects reflected light, scattered light, or emitted light (such as infrared thermal radiation) from the target object through a set of optical lenses. Similar to ordinary lenses, this stage achieves light convergence and initial imaging, but adds optical interfaces and optical path designs required for subsequent spectral separation.

- Spectral Separation Stage (Core)This is the key link that distinguishes multispectral lenses from ordinary lenses. Special optical components decompose mixed light into 3-15 preset discrete narrow bands (typically with a bandwidth of 10-100nm). Light of different wavelengths is accurately separated into different optical paths or imaging areas due to differences in physical properties (such as refractive index and diffraction angle).

- Band-Specific Imaging StageThe separated light of each band is projected onto the corresponding image sensor (or different pixel areas of the same sensor). The sensor converts the light signal of each band into an electrical signal, recording the brightness and spatial distribution information of the target in each spectral dimension.

- Signal Processing and Fusion StageThe electrical signals of each band are preprocessed through amplification, correction, noise reduction, and other steps. Through image registration and fusion technologies, multi-band images are combined into a multi-dimensional data set containing rich spectral information for subsequent analysis and use.

3.2 Detailed Explanation of Mainstream Spectral Separation Technologies

The core difference between multispectral lenses lies in the adopted spectral separation technology. Below are four mainstream solutions:

| Technology Type | Working Principle | Core Advantages | Limitations | Typical Applications |

| Prism Spectroscopy | Uses prism’s refractive index difference to disperse light into spectra, captured synchronously by multiple sensors. | High light flux, no moving parts, suitable for high-speed imaging | Large volume, high cost, complex optical alignment | Remote sensing satellites, industrial inspection |

| Grating Spectroscopy | Relies on light diffraction; periodic structure separates light by different wavelengths’ diffraction angles. | High spectral resolution, good dispersion linearity | Low energy utilization rate, sensitive to stray light | Scientific research instruments, high-precision inspection |

| Filter Array | Micro-filter array on sensor, each pixel corresponding to a specific band (like extended Bayer filter). | Compact structure, single-exposure imaging, low cost | Limited number of spectral channels, low pixel utilization | UAVs, portable devices |

| Tunable Filtering | LCTF/AOTF technology; electrical control switches transmitted wavelengths in real time, no mechanical movement. | Dynamically selectable bands, high flexibility | Low light transmittance, limited response speed | Medical imaging, dynamic monitoring |

3.3 Key Optical Components and Principles

- Spectral Splitting Elements

- Prism: Utilizes the dispersion effect; the shorter the wavelength, the greater the refractive index and the larger the deflection angle (e.g., violet light deflects more than red light).

- Grating: Utilizes the diffraction effect; the longer the wavelength, the larger the diffraction angle, forming an equidistant spectral distribution.

- Filter: Based on the principle of selective absorption/transmission, only allowing specific wavelengths to pass through through multi-layer coating or special materials.

- Special Filtering Technology

- Fabry-Perot Interference Filter: Forms an optical cavity through two parallel reflectors, allowing only incident light that meets the resonance condition to pass through; wavelength tuning is achieved by changing the cavity spacing.

- Liquid Crystal Tunable Filter (LCTF): Controls the arrangement of liquid crystal molecules through an electric field, changes the polarization state of light, and achieves selective transmission of specific wavelengths.

- Image Sensor Adaptation Multispectral systems usually adopt two schemes:multi-sensor array (corresponding to different bands) orsingle sensor + filter wheel (switching bands in a time-sharing manner). Advanced systems adopt a snapshot design, integrating micro-lens arrays with filters to achieve single-exposure multi-band imaging and eliminate motion artifacts.

3.4 Core Differences: Multispectral vs. Hyperspectral Imaging

| Characteristics | Multispectral Imaging | Hyperspectral Imaging |

| Number of Bands | 3-15 discrete bands | Hundreds of continuous bands |

| Spectral Resolution | Low (10-100nm) | Very high (1-10nm) |

| Data Volume | Small, high processing efficiency | Large, requiring dedicated processing algorithms |

| Application Scenarios | Agricultural monitoring, remote sensing, machine vision | Precision agriculture, mineral exploration, environmental monitoring |

3.5 Typical Application Cases

The working principle of multispectral imaging lenses endows them with unique value in many fields:

- Agriculture: Distinguish crop health status through near-infrared bands (healthy crops have high reflectivity).

- Remote Sensing: Monitor water pollution (different pollutants have characteristic absorption in specific bands).

- Medical: Detect skin cancer, fundus lesions and other diseases through imaging in specific bands.

- Industry: Identify surface defects of products and detect food freshness and component analysis.

4. Applications in Smart Agriculture

TOWIN multispectral imaging lenses support end-to-end smart agriculture scenarios, from seedling to harvest:

- Crop Growth Monitoring

- Capture NDVI (Normalized Difference Vegetation Index) to assess chlorophyll content.

- Monitor single plants (via 32x optical zoom) or large areas (2 km coverage radius when mounted at 40m height).

- Example: Detect yellowing leaves 7-10 days earlier than manual inspection.

- Pest & Disease Early Warning

- Identify spectral changes caused by pests (e.g., aphids) or fungi (e.g., wheat rust) before visible symptoms appear.

- Compatible with UAVs for 1.5 km² farm surveys in 10 minutes.

- Fertilizer & Water Management

- Analyze nitrogen content via GNDVI (Green NDVI) to avoid over-fertilization.

- Measure leaf water content using 900 nm band to optimize irrigation schedules.

- Yield Prediction

- Combine spectral data with spatial mapping to estimate yield per mu (accuracy ≥90%).

- Support data export to agricultural management platforms (e.g., FarmLogs, AgriWebb).

5. TOWIN Multispectral Imaging Lenses

TOWIN offers 3 main series of multispectral lenses for smart agriculture, covering different mounting types and application needs:

5.1 Product Series Overview

| Parameter | Agricultural Mini Lens | Industrial Agri Lens | Security Agri Lens |

| Series | Agricultural Mini Lens | Industrial Agri Lens | Security Agri Lens |

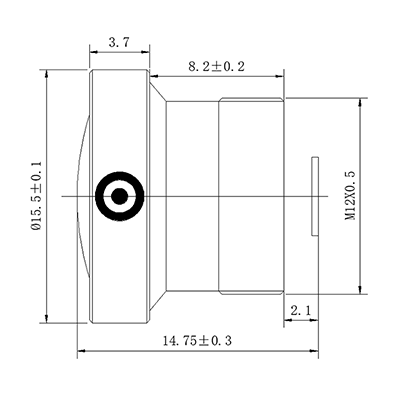

| Mount Type | M12/S-Mount | C-Mount | CS-Mount |

| Spectral Bands | 4-6 bands (450-950 nm) | 6-8 bands (400-1000 nm) | 8-12 bands |

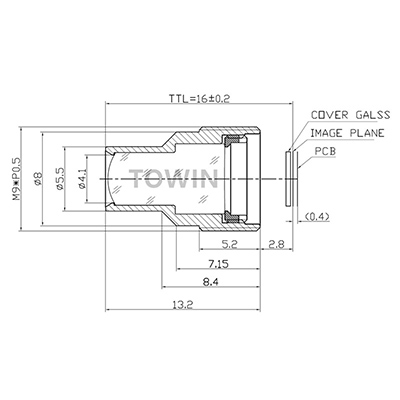

| Key Features | Compact (ø14-24mm), low power, IR-corrected | High resolution (5MP), low distortion | DC Auto Iris, day/night mode |

| Target Application | Drone-mounted small farm monitoring | Fixed camera for large-scale farmlands | 24/7 orchard pest monitoring |

| Model Examples | S4621018F67, CCL121625MPRF | S7018020F, S6822023F (IMX335) | A5120020F69, S01714012013IRB9 |

5.2 Customization Capabilities

- Band Customization: Adjust target wavelengths (e.g., add 730 nm band for rice monitoring).

- Mount Adaptation: Modify M12/C/CS mounts to fit specific agricultural cameras.

- Environmental Design: IP67-rated lenses for outdoor use (resist rain/dust).

6. Why Choose TOWIN Multispectral Lenses?

- Professional Manufacturing Experience

- 15+ years in optical lens design; ISO 9001 certified factory.

- In-house R&D team (10+ engineers) supports agricultural-specific solutions.

- Full Product Range

- Cover M12/C/CS mounts, 4-12 spectral bands, and 1-5MP resolutions—one-stop sourcing.

- Fast & Easy Service

- 24-hour response for lens selection (via info@towin-elec.com).

- 3-7 day delivery for standard models; 15-20 days for customization.

- Agriculture-Optimized Features

- Low-light sensitivity (works in dawn/dusk) and anti-glare coating (reduce sunlight interference).

- Compatible with major agricultural cameras (e.g., Hikvision, Dahua) and drones.

FAQs

What’s the difference between multispectral lenses and ordinary lenses?

Ordinary lenses only capture visible light (RGB), while multispectral lenses add near-infrared/other bands to analyze crop health indicators (e.g., chlorophyll) that are invisible to the naked eye.

How do I select the right TOWIN multispectral lens?

- For drones: Choose M12 series (compact, lightweight).

- For fixed farm cameras: Choose C/CS series (high resolution).

- Contact our team with your camera model and application (info@towin-elec.com) for free advice.

Does TOWIN offer customization for specific crops?

Yes. We customize spectral bands (e.g., 680 nm for corn, 720 nm for grapes) and lens parameters based on crop types.

What’s the delivery time for TOWIN lenses?

- Standard models: 3-7 business days (shipped from China).

- Custom models: 15-20 business days.

Is there after-sales support?

Yes. All TOWIN lenses come with a 1-year warranty. Our team provides technical support via email/online meeting.

1.7mm Wide-Angle TOF lens

Conclusion

Multispectral imaging lenses are the “eyes” of smart agriculture—they turn invisible light into actionable data, reducing costs and increasing yields. As a professional optical supplier, TOWIN combines advanced spectral tech, full product coverage, and fast service to meet your agricultural needs.

Whether you need a drone-mounted M12 lens for small farms or a high-resolution C-mount lens for large plantations, TOWIN has you covered. Contact us today at info@towin-elec.com to get a free lens selection guide and quote!