Zero Distortion Lens vs. Standard Optical Lenses

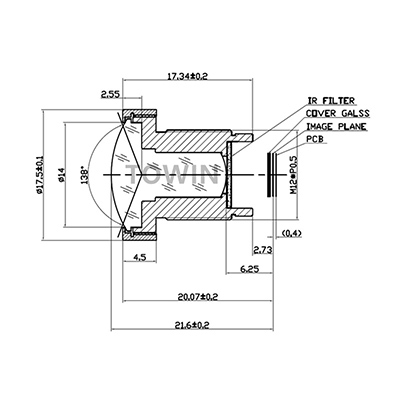

3.7mm 1/3″ HD CCTV M12 Pinhole lens

12/31/2025

1/3.2″ Φ2.8 220° M12 Fisheye lens

01/04/2026Table of Contents

Introduction

In the field of optical imaging, traditional standard optical lenses generally suffer from geometric distortion issues such as barrel distortion and pincushion distortion — the edges of objects are stretched or compressed during imaging, leading to inconsistent proportions between the image size and the actual object dimensions. Zero Distortion Lens optimize curvature, use aspherical designs, and integrate telecentric systems for precise light control. This enables them to reduce distortion rates to below 0.1%, even approaching the theoretical “zero-distortion” limit.

TOWIN, a pro optical provider, meets market needs with zero-distortion lens R&D for precise, reliable imaging.

Core Comparison: Zero Distortion Lens vs. Standard Optical Lenses

| Comparison Dimensions | Zero Distortion Lens (TOWIN) | Standard Optical Lens |

| Core Parameters | Distortion rate ≤0.1%, resolution 20%+ higher, stable large FOV | Distortion rate 1%-5%, basic resolution, FOV expansion increases distortion |

| Performance | Excellent distortion correction, high transmittance, strong environmental adaptability | Obvious edge distortion, general transmittance, poor stability in harsh environments |

| Core Advantages | High precision, customized solutions, reliable quality, cost-effective | Low cost, simple structure, strong versatility, easy procurement |

| Application Scenarios | Precision measurement, industrial/robot/medical high-precision imaging | Daily photography, civil surveillance, basic non-precision observation |

| Core Design Concept | Focus on high-precision imaging with distortion correction | Balance cost/FOV/basic imaging quality |

A core dimensional comparison reveals that zero distortion lenses outperform standard optical lenses across all key metrics required for high-precision scenarios, while standard optical lenses are more suitable for basic imaging applications with low accuracy requirements.

TOWIN’s Competitive Advantages in Zero Distortion Lens Manufacturing

As a professional optical lens supplier, TOWIN’s Zero Distortion Lenses stand out with four core strengths: stable quality, easy adaptability, efficient procurement, and broad scenario applicability, making them a cost-effective choice for businesses in industrial, security, automotive, and other sectors.

Low distortion 5-Megapixel lens

1. Professional Manufacturing + Flexible Customization: Controlled Quality, Tailored to Special Needs

TOWIN has deep expertise in the optical lens industry, with a core positioning of “PROFESSIONAL-ALL-EASY-FAST”. It boasts full-process capabilities for independent design and local manufacturing of zero distortion lenses (with production bases located in China). From optical structure optimization to distortion correction technologies, all processes are subject to standardized control:

- Stable Quality: Backed by a mature optical R&D system, TOWIN’s zero distortion lenses meet high industrial and security-grade standards for imaging accuracy and distortion control thresholds. This eliminates detection errors and surveillance blurriness caused by distortion, reducing after-sales rework costs for businesses.

- Flexible Customization: Custom solutions are available based on customers’ terminal device parameters (e.g., interface specifications, imaging requirements). Without relying on third-party OEM services, TOWIN can quickly respond to niche and personalized demands, helping businesses gain a competitive edge in segmented markets.

2. Full-Scenario Product Matrix

TOWIN offers a comprehensive range of zero distortion lenses covering M12/S-Mount, C-Mount, and CS-Mount interfaces, catering to diverse needs in machine vision, traffic surveillance, medical imaging, and other fields:

- M12 Lenses: Featuring low distortion, wide-angle, and macro designs, these lenses are ideal for narrow-space applications such as drone inspections and pipeline inner wall detection.

- C-Mount Lenses: Optimized for industrial cameras, they meet the requirements of high-speed motion capture and high-precision measurement tasks.

- CS-Mount Lenses: Integrated with IR correction and multi-coating technologies, these lenses are compatible with day-night dual-use security cameras, minimizing chromatic aberration and glare interference.

3. Balanced Performance and Cost

Through modular design and large-scale production, TOWIN maintains high-performance metrics including ultra-low distortion (<0.1%) and high resolution (12+ megapixels) while reducing manufacturing costs. Its 3.5x zero-distortion core module (measuring 56.4×29.6×39.75mm) delivers high-definition distortion-free imaging in a compact form factor, with a price approximately 20% lower than comparable products. This makes it a cost-effective choice for inspection robots and automated production lines.

4. Rapid Response and Customization Capabilities

Leveraging local Chinese supply chains and flexible production lines, TOWIN provides end-to-end customization services from optical design to mass production. Sample testing can be arranged within 72 hours, and mass production delivery can be completed in 2 weeks. For example, for a semiconductor inspection customer, TOWIN customized a lens with ultra-low distortion (<0.05%) and a large image circle (1-inch format), reducing measurement errors from the 0.1mm level to 0.0017mm to meet nanoscale precision requirements.

5. In-Depth Penetration of Application Scenarios

TOWIN’s zero distortion lenses have been widely adopted in precision manufacturing, intelligent transportation, medical research, and other sectors:

- Industrial Inspection: In automotive component dimension measurement, lenses with a distortion rate of 0.08% control measurement errors within ±1μm.

- Machine Vision: Inspection robots equipped with TOWIN’s 3.5x zero-distortion core module enable accurate identification of pipeline cracks and high-voltage line defects.

- Medical Imaging: Laser Speckle Contrast Imaging (LSCI) systems adopt TOWIN’s low-distortion lenses to ensure the accuracy of blood flow analysis.

Low distortion lens 12-Megapixel M12 F2.2 CCTV lens

TOWIN 5 Zero Distortion Lens: Complete Guide for Security & Industrial Applications

As a professional optical lens supplier, TOWIN’s low distortion lens series stands out with “ultra-low distortion, high resolution, and multi-interface compatibility.” Covering two mainstream mounts (M12/S-Mount and C-Mount), these lenses are tailored for high-frequency scenarios such as security surveillance, machine vision, and industrial inspection.

1. S03513206628F: Security-Specific, Ultra-Low Distortion + IR-Ready

Core Positioning

- A 13-megapixel ultra-low distortion M12 wide-angle CCTV lens designed exclusively for security surveillance, featuring a built-in IR filter for stable day/night imaging.

Key Specifications

| Core Parameters | Details |

| Image Format | 1/3.2″ |

| Focal Length | 3.5mm (Wide-Angle) |

| Resolution | 13 MP |

| TV Distortion | <0.01% (Ultra-Low) |

| Aperture | F2.8 (Fixed) |

| Mount Type | M12X0.5 (S-Mount) |

| Field of View (FOV) | 78°(D) / 66°(H) / 52°(V) |

| Minimum Object Distance (MOD) | 0.1m |

| Structure | 3G2P+IRCF (Built-in IR Filter) |

Key Advantages

- Ultra-low distortion (<0.01%) ensures surveillance footage is free of stretching or deformation, accurately restoring details like human faces, license plates, and object contours.

- 13MP high resolution + F2.8 large aperture delivers clear imaging in low-light environments; the built-in IR filter enables seamless day/night switching for security cameras.

- Standard M12 interface screws directly into PCB cameras without adapters, offering easy installation for space-constrained devices (e.g., small surveillance cameras, access control cameras).

Application Scenarios

- Residential security monitoring, store surveillance, access control camera systems, outdoor lightweight monitoring terminals.

Ultra-Low-distortion 13-Megapixel M12 CCTV lens

2. C7501028M8: Industrial Machine Vision, Manual Adjustment + High Compatibility

Core Positioning

- An 8-megapixel C-Mount industrial lens engineered for machine vision, supporting manual adjustments to fit industrial inspection and automated production scenarios.

Key Specifications

| Core Parameters | Details |

| Image Format | 2/3″ |

| Focal Length | 75mm (Medium-Long) |

| Resolution | 8 MP |

| TV Distortion | <0.02% (Ultra-Low) |

| Aperture | F2.8~16 (Manual) |

| Mount Type | C-Mount (Flange Focal Distance: 17.526mm) |

| Field of View (FOV) | 6.5°(H) / 5.1°(V) |

| Minimum Object Distance (MOD) | 0.8m |

| Operation | Manual Iris + Manual Focus + Manual Zoom |

Key Advantages

- Industrial-grade low distortion (<0.02%) guarantees dimensional accuracy for machine vision tasks (e.g., product defect detection, part dimension measurement).

- Wide aperture range (F2.8~16) adapts flexibly to varying light intensities in industrial settings, performing reliably in both strong and weak light.

- Standard C-Mount interface is compatible with USB, GigE, and 3D industrial cameras, integrating seamlessly with automated production lines and machine vision inspection equipment.

Application Scenarios

- Industrial product defect detection, high-precision part dimension measurement, visual guidance for automated production lines, industrial robot accessories.

F2.8 Zero Distortion Lens

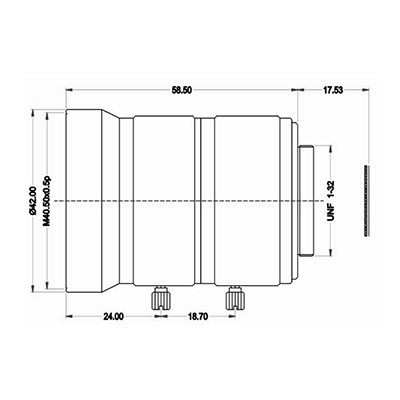

3. C3511028M20: 35mm Mid-Range Industrial Lens, Balancing Precision & Coverage

Core Positioning

- An 35mm mid-range industrial-grade low distortion lens focused on “mid-distance high-precision inspection.” It balances detection range and detail accuracy, making it a cost-effective choice for industrial applications.

Key Specifications

| Core Parameters | Details |

| Image Format | 1.1″ |

| Focal Length | 35mm (Mid-Range, Balancing FOV & Precision) |

| Resolution | 20 MP |

| TV Distortion | <0.02% (Ultra-Low) |

| Aperture | F2.8~22 (Manual Iris for Complex Industrial Light) |

| Mount Type | C-Mount (Compatible with Industrial Cameras) |

| Field of View (FOV) | 28°(D) / 23°(H) / 17°(V) |

| Minimum Object Distance (MOD) | 0.2m |

| Operation | Manual Iris + Manual Focus + Manual Zoom (Flexible for Industrial Scenarios) |

Key Advantages

- Golden Mid-Range Focal Length: 35mm strikes a balance between short focal length (wide coverage) and long focal length (high precision), covering mid-size inspection areas (e.g., full PCB board inspection, small equipment verification) while maintaining <0.02% ultra-low distortion for accurate detail measurement.

- Industrial Compatibility: Standard C-Mount interface integrates seamlessly with USB, GigE, and 3D industrial cameras, connecting directly to automated production lines and machine vision systems without additional adaptation costs.

- Rugged & Reliable Design: Complies with TOWIN’s industrial lens standards for temperature resistance and shockproof performance, supporting 24/7 continuous operation (ideal for factory production lines) and reducing equipment failure and maintenance costs.

Application Scenarios

- PCB soldering quality inspection, electronic component appearance defect identification, small product packaging integrity verification, visual positioning for automated assembly lines, mid-distance industrial part dimension measurement.

20-35mm-20MP-C-mount-low distortion FA lens-lens

4. C10001035M8: Long-Focal Industrial Lens, Specialized for Long-Distance Inspection

Core Positioning

- An 8-megapixel long-focal C-Mount FA industrial lens designed exclusively for long-distance machine vision inspection, offering high stability and precision.

Key Specifications

| Core Parameters | Details |

| Image Format | 2/3″ |

| Focal Length | 100mm (Long-Focal) |

| Resolution | 8 MP |

| TV Distortion | <0.02% (Ultra-Low) |

| Aperture | F3.5~32 (Manual) |

| Mount Type | C-Mount |

| Field of View (FOV) | 5.1°(H) / 3.9°(V) |

| Minimum Object Distance (MOD) | 0.8m |

| Operation | Manual Iris + Manual Focus + Manual Zoom |

Key Advantages

- 100mm long focal length + <0.02% low distortion captures fine details from a distance (e.g., micro-defects on precision parts, long-distance workpiece positioning).

- Wide aperture range (F3.5~32) adapts to complex light conditions in industrial environments, performing reliably in bright workshops and low-light inspection rooms alike.

- Complies with FA (Factory Automation) industrial standards, compatible with industrial-grade machine vision cameras, and excels in temperature resistance and shockproof performance for long-term continuous operation.

Application Scenarios

- Long-distance industrial inspection, precision electronic component identification, large equipment part verification, warehouse logistics workpiece positioning.

100mm C-Mount Zero Distortion Lens

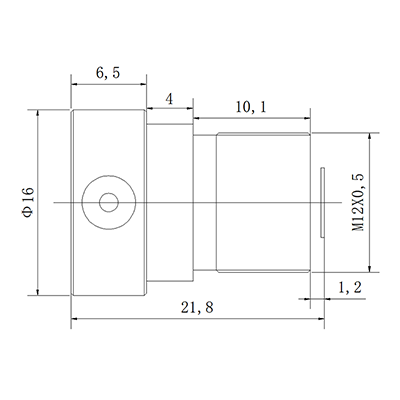

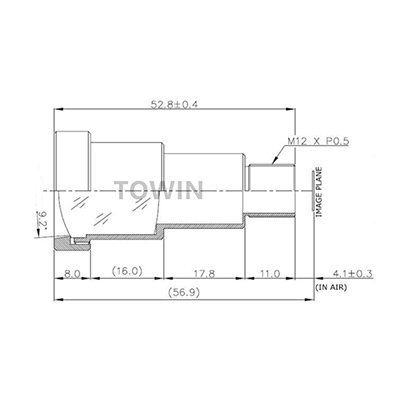

5. CCL1250MP: Multi-Sensor Compatible, Versatile for Security & Light Industry

Core Positioning

- A megapixel-grade M12/S-Mount low distortion lens supporting multi-sensor size compatibility, suitable for both security surveillance and light industrial inspection needs.

Key Specifications

| Core Parameters | Details |

| Image Format | 1/2″, 2/3″ (Dual Compatibility) |

| Focal Length | 50mm (Medium-Long) |

| Resolution | Megapixel-Grade |

| Distortion | <0.03% (Low Distortion) |

| Aperture | F2.5 (Fixed) |

| Mount Type | M12x0.5 (S-Mount) |

| Field of View (FOV) | 9.2°(D) / 7.2°(H) / 5.1°(V) |

| Minimum Object Distance (MOD) | 0.4m |

| Dimensions | Φ27×52.8mm (Miniaturized Design) |

Key Advantages

- Dual compatibility with 1/2″ and 2/3″ sensors allows businesses to adapt to different terminal device specifications without replacing lenses, reducing inventory costs.

- 50mm medium-long focal length + <0.03% low distortion meets both long-distance security surveillance (e.g., campus perimeter monitoring) and short-distance light industrial inspection (e.g., small part appearance checks).

- Miniaturized M12 design (Φ27×52.8mm) fits space-constrained terminal products, enabling flexible installation.

Application Scenarios

- Campus long-distance security monitoring, light industrial part appearance inspection, portable testing equipment, automotive auxiliary imaging devices.

50mm M12 Zero Distortion Lens

Selection Summary: Match Your Needs Quickly

| Application Requirements | Recommended Model |

| Security Surveillance (Day/Night, High Resolution) | S03513206628F |

| Industrial Short-Distance Inspection (Manual Adjustment) | C7501028M8 |

| Industrial Long-Distance Inspection (Long Focal Length) | C10001035M8 |

| Multi-Device Compatibility (Security + Light Industry) | CCL1250MP |

| 35mm Mid-Range Industrial Inspection | C3511028M20 |

Practical Applications of TOWIN Zero Distortion Lenses

With ultra-low distortion rates approaching the theoretical limit (<0.1%), high resolution, and strong environmental adaptability, TOWIN’s zero distortion lenses have been deeply applied in industrial inspection, intelligent devices, medical research, and other fields:

1. Industrial Inspection & Precision Manufacturing

Application Scenarios

- Semiconductor chip packaging inspection, automotive component dimension measurement, electronic component surface defect screening.

Technical Advantages

- Nanoscale Precision: In semiconductor inspection, TOWIN’s customized 1-inch format zero distortion lens (distortion rate <0.05%) reduces measurement errors to ±1μm, meeting the precision requirements of lithography machine alignment and wafer defect localization.

- Wide Field of View Compatibility: The five-lens structure (including aspherical elements) supports an 83° field of view, covering a larger area in a single image capture and reducing inspection cycle time. For example, in automotive engine block inspection, the lens can capture multiple hole dimensions simultaneously, improving efficiency by 30%.

2. Intelligent Inspection & Robot Vision

Application Scenarios

- Pipeline inner wall crack detection, high-voltage line risk identification, warehouse logistics goods sorting.

Technical Advantages

- Compact Design: The 3.5x zero-distortion core module (56.4×29.6×39.75mm) fits the narrow space constraints of inspection robots, delivering high-definition distortion-free imaging.

- Dynamic Capture Capability: Mounted on drones for pipeline checks, the lens avoids edge stretching, keeping crack measurement errors <0.02mm for precise maintenance.

25mm Low Distortion Machine Vision Lens

3. Medical Imaging & Scientific Research

Application Scenarios

- Laser Speckle Contrast Imaging (LSCI), Photoacoustic Imaging (PAM), endoscopic minimally invasive surgery navigation.

Technical Advantages

- Blood Flow Dynamic Visualization: LSCI systems equipped with TOWIN’s low-distortion lenses (distortion rate <0.08%) eliminate image deformation, enabling accurate calculation of the Skin Blood Flow Index (BFI) and assisting in the early diagnosis of diabetic foot ulcers.

- Multi-Modal Imaging Compatibility: The lens covers 400–1000nm (visible to near-IR), enabling 50μm resolution for deep tissue photoacoustic imaging.

4. Traffic Surveillance & Intelligent Security

Application Scenarios

- Highway vehicle speed measurement, urban intersection traffic violation capture, airport perimeter intrusion detection.

Technical Advantages

- Day-Night Dual-Use Performance: CS-Mount zero distortion lenses integrated with IR correction and multi-coating technologies maintain a distortion rate of <0.1% even in low-light conditions (0.001lux), ensuring license plate recognition accuracy exceeds 99%.

- Wide-Angle Distortion-Free Imaging: 120° field-of-view lenses cover three lanes of traffic monitoring, eliminating edge vehicle deformation and avoiding speed measurement data deviations.

5. Consumer Electronics & Emerging Technologies

Application Scenarios

- AR/VR device optical modules, 3D sensors, smartphone multi-camera systems.

Technical Advantages

- Lightweight & Slim Design: M12/S-Mount zero distortion lenses with a thickness of only 8mm fit the compact space of wearable devices while supporting 12-megapixel high resolution.

- Low Chromatic Aberration Performance: Achromatic design reduces longitudinal and lateral chromatic aberration, improving point cloud accuracy in 3D structured light projection and enhancing the security of face recognition payment systems.

Low distortion wide angle M12 s-mount lens

FAQs

Q1: What is a zero distortion lens?

A: A zero distortion lens minimizes image deformation via advanced designs like aspherical lenses and low-dispersion glass. It doesn’t reach absolute zero distortion, but keeps rates extremely low (usually <0.1%, <0.01% for high-precision). This minimal distortion is imperceptible to the human eye and can be easily compensated for by image processing algorithms.

Q2: What are the common types of distortion in zero distortion lenses?

A: Two common types of distortion exist:

- Barrel Distortion: Image edges bulge outward, which is prevalent in wide-angle lenses.

- Pincushion Distortion: Image edges shrink inward, which is commonly seen in telephoto lenses.

Q3: What are the core differences between zero distortion lenses and standard optical lenses?

A: The core differences lie in distortion control, optical design, and application scenarios:

- Standard Optical Lenses: No specialized optimization for distortion control; only suitable for scenarios with low accuracy requirements.

- Zero Distortion Lenses: Use aspherical lenses, low-dispersion glass, and symmetry to cut distortion <0.1% (<0.01% high-precision), ensuring image authenticity.

Q4: Can standard optical lenses replace zero distortion lenses?

A: Standard optical lenses can be used as a temporary alternative in non-precision scenarios (e.g., general surveillance, daily photography). They can’t replace zero-distortion lenses in precise tasks like industrial inspection, as distortion causes errors and failures.

Conclusion

Today, zero distortion lenses have emerged as the core component of high-performance optical solutions. Leveraging its technical prowess in pushing the boundaries of distortion control — spanning from standard models with <0.1% distortion to ultra-high-precision variants with <0.01% distortion — TOWIN combines flexible customization capabilities and cost-efficient manufacturing processes to deliver comprehensive product support for industrial machine vision inspection, security surveillance system upgrades, and compact medical and consumer device integration.