TOWIN’s 5 Machine Vision Lenses: An Introduction

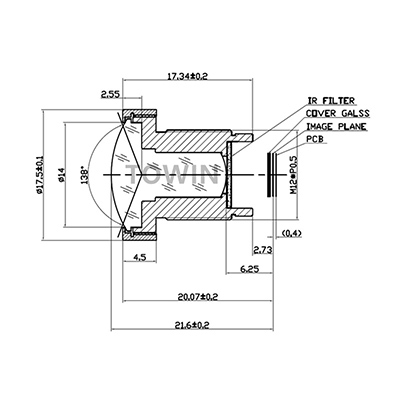

7.5mm 1/2.3″ 45° M12 Low distortion lens

12/22/20255 Low Distortion Lens Specifically for Drones

12/23/2025Table of Contents

Introduction: TOWIN Machine Vision Lenses

In the field of machine vision lenses, TOWIN has become an indispensable core supplier in machine vision applications due to its innovative machine vision optical solutions, superior high-definition imaging performance, and customized full-lifecycle services. Whether for routine visual inspection needs in basic industrial production lines or high-performance precision scenarios such as high-end electronics manufacturing and automotive parts inspection, TOWIN machine vision lenses can precisely match the requirements, demonstrating an extreme pursuit of optical precision and scenario adaptability.

TOWIN Lens Series Overview: Why Does Industrial Automation Rely on High-Precision Vision Solutions?

In machine vision systems, the lens is a key component for light signal acquisition and image formation, and its performance directly affects detection accuracy, measurement reliability, and environmental adaptability. The TOWIN lens series provides end-to-end support for industrial automation, from defect identification to geometric measurement, through innovative optical design and scenario-based optimization.

1. Precise Light Signal Acquisition: The Cornerstone of High-Quality Images

- High-Resolution Imaging: Aspherical lenses and apochromatic design eliminate aberrations; a 5-megapixel telecentric lens achieves 5μm pixel matching accuracy, capable of capturing defects as small as 0.02mm.

- Large Aperture Optimizes Light Intake: The F/1.8 large aperture enhances low-light imaging brightness, ensuring clear and blur-free character recognition on high-speed production lines (>2m/s) in food packaging.

- Anti-Reflective Coating Reduces Interference: Multi-layer AR coating achieves 99.5% transmittance, effectively suppressing reflections and accurately identifying scratches and bubbles in automotive glass inspection.

C-mount Machine Vision lenses

2. Geometric Accuracy Guarantee: From “Seeing” to “Measuring Accurately”

- Telecentric Optical Path Eliminates Distortion: Parallel light design eliminates perspective distortion, ensuring aperture measurement errors ≤1μm in precision machining, replacing traditional measuring tools.

- Low Distortion Rate Control: Distortion rate <0.05%, ensuring accurate identification of 0.1mm pitch pads in PCB board inspection, avoiding misjudgments of short circuits/open circuits.

- Extended Depth of Field Adapts to Multiple Heights: Optimized depth of field for zoom lenses allows for simultaneous inspection of multiple sides (screen, buttons) of the mobile phone frame in a single shot on 3C product assembly lines.

3. Environmental Adaptability: Unfazed by Extreme Industrial Challenges

- Mechanically Rugged and Vibration Resistant: The metal casing and integrated lens barrel design ensure stable imaging even under vibration (≤10Hz) during robot vision guidance.

- IP67 Protection and Contamination Prevention: Sealing rings and waterproof adhesive filling provide resistance to corrosive gases in chemical production lines; the lens is coated with an acid and alkali resistant film to extend its lifespan.

- Temperature Compensation and Stable Performance: Temperature-resistant glass and structural compensation ensure normal identification of damaged frozen food packaging at -20℃ in cold chain logistics.

4. The System-Enabling Value of TOWIN Lenses

- Light Source Synergy: Optimized aperture and depth of field enhance defect contrast;

- Camera Compatibility: Multi-interface (C/F interface) compatible with brands such as Basler and Dalsa;

- Algorithm Fusion: Reserved feature labeling interface supports optimized detection using deep learning models such as YOLO.

TOWIN provides core optical support for industrial automation with “precise adaptation + stable reliability,” facilitating upgrades and quality improvement.

TOWIN Lenses: Core Functions & Application Scenarios Corresponding Table

| Lens Type | Core Functions | Application Scenarios | Key Specifications |

| M12 Telecentric Lens | Eliminates perspective distortion; ultra-low distortion for precision measurement/inspection | Semiconductor wafer inspection; automotive component measurement; 3D reconstruction; PCB aperture measurement | M12/S Mount; Distortion < 0.1%; 5MP; WD 20-200mm |

| S-Mount HD Low Distortion Lens | High-res imaging; edge distortion control; compact design | Electronic component defect inspection; PCB solder joint screening; face recognition | M12/S Mount; 1-8MP; Distortion < 1%; Focal Length 1.8-6mm |

| Wide-Angle/Fisheye Lens | Ultra-wide FOV; low-light adaptation; easy integration | Workshop panoramic monitoring; logistics positioning; UAV 360° imaging | M12/S/C/CS Mount; FOV 120°-180°; 8MP; Aperture f/2.0-f/2.8 |

| IR-Corrected Low-Light Lens | Enhanced low-light collection; consistent day-night imaging; glare reduction | Night production line inspection; outdoor equipment monitoring; dim workshop material identification | M12/S/C/CS Mount; Aperture f/1.0; IR Cut Filter; -20℃~60℃ |

| C-Mount Industrial Lens | High-pixel HD imaging; industrial-grade stability; high-speed capture | Automotive assembly inspection; food packaging check; intelligent transportation capture | C Mount; 12MP; Focal Length 2.8-50mm; Vibration/dust-proof |

| Medical Imaging Special Lens | Ultra-high resolution; low distortion; biocompatible & disinfection-resistant | Endoscopic surgery imaging; pathological section inspection; dermatoscopic lesion identification | Custom Mount; 50MP; Distortion < 0.1%; Hydrophobic coating |

The Concept of Machine Vision Lenses

Through optical innovation and system synergy, the Machine Vision lenses provides industrial automation with precise visual acquisition capabilities that surpass the human eye, driving the upgrade of production towards intelligence and flexibility.

1. Core Value: From “Replacing the Human Eye” to “Surpassing the Human Eye”

- High Resolution: Aspherical lenses + apochromatic technology achieve 5μm pixel matching accuracy at 5 megapixels, detecting defects down to 0.02mm (such as semiconductor wafer particle contamination).

- Low Distortion: Distortion rate <0.05%, ensuring consistent image edge and center dimensions, avoiding misjudgment of 0.1mm solder pads on PCB boards.

- High-Speed Acquisition: Combined with a high frame rate camera, stable imaging in a 2m/s production line, 10 times faster than manual methods (e.g., food packaging label inspection).

- Environmental Resistance: IP67 protection + corrosion-resistant coating, adaptable to harsh environments such as chemical and food processing, extending lifespan by 3 times.

- Telecentric Optical Path: Eliminates perspective distortion, achieving ±1μm flatness measurement accuracy within a 100mm field of view, replacing micrometers (e.g., automotive gear inspection).

- Depth of Field Extension: Completes multi-height inspection of the phone’s mid-frame (screen, buttons) in a single shot, reducing changeover time by 80%.

2. Intelligent Fusion: From “Image Acquisition” to “Decision Center”

- Light Source-Lens Collaboration: Optimizes aperture and depth of field, matches ring light/backlight, improving the signal-to-noise ratio of metal scratches by 30% (e.g., automotive glass inspection).

- Seamless Algorithm Integration: Reserves feature labeling interfaces, supports deep learning models such as YOLO, and achieves autonomous optimization of defect classification (scratches/stains) and dimensional measurement.

- System-Level Solution: Multi-interface compatibility (C/F interface), rapid integration with Basler and Dalsa cameras, reducing development cycle by 50%.

3. Industry 4.0 Driven: Flexible Manufacturing and Data Closed Loop

- Flexible Adaptation: Zoom lens + adjustable aperture support co-line inspection of multiple product models (e.g., electronic components of different sizes), with changeover time <10 minutes.

- Data-Driven Optimization: Image data is fed back to the production system to dynamically adjust welding temperature/injection pressure, reducing product defect rate from 0.5% to 0.02% (e.g., 3C assembly lines).

- Predictive Maintenance: Monitors wear on robotic arm joints, providing early warnings of malfunctions, reducing downtime risk by 60%.

40mm C mount IR corrected machine vision lenses

TOWIN 5 Lens Technical Specifications Comparison: Which One is Right for Your Application?

TOWIN’s 5 core machine vision lenses each boast unique technical highlights, adapting to the inspection needs of different industrial scenarios. The following precise parameter breakdown, core advantage analysis, and scenario matching suggestions will help you quickly identify the suitable model.

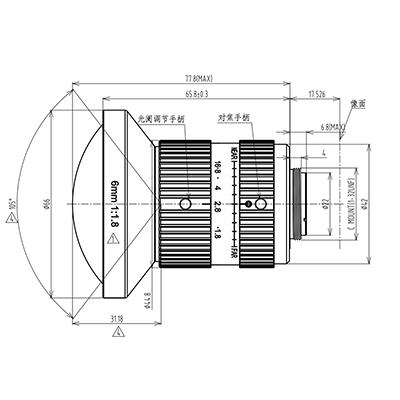

1. Wide-Angle Lens (C0611018M20): A Powerful Tool for Industrial Inspection with Wide Field of View

As an industrial lens focusing on “wide-area capture,” the C0611018M20, with its ultra-wide field of view and high-definition imaging capabilities, is the preferred choice for large-area inspection scenarios.

Key Technical Parameters:

- Imaging Format: 1.1″, compatible with mainstream industrial camera sensors;

- Focal Length: 6mm, with a diagonal field of view of 118° and a horizontal field of view of 105°, providing wide coverage;

- Resolution: 20 megapixels, excellent detail capture capability;

- Aperture: F1.8~16, sufficient light intake in low-light environments;

- Distortion Rate: ≤2.5%, meeting the geometric accuracy requirements of conventional inspection;

- Minimum Object Distance (M.O.D.): 0.1m, supporting close-range large-area imaging;

- Interface Type: C-Mount, strong compatibility.

Core Advantages: Ultra-wide field of view reduces blind spots; 20MP high-definition resolution combined with a large F1.8 aperture covers a large inspection area while clearly capturing minute defects; manual focus and zoom design adapt to flexible adjustment needs.

Suitable Scenarios:

- Overall appearance inspection of electronic devices (e.g., panoramic defect screening of mobile phone and computer casings);

- Food / 1. Integrity inspection of entire cartons of pharmaceutical packaging;

- Panoramic monitoring and material positioning of production lines;

- Printing quality inspection of large-area printed materials (such as posters and circuit board layouts).

6mm Wide-angle C-Mount Machine Vision lens

2. Ultra-low distortion FA lens (C3511028M20): The precise choice for precision measurement and identification

Designed specifically for industrial automation (FA) scenarios, it boasts near-extremely low distortion, making it a core piece of equipment for high-precision inspection and identification tasks.

Core technical parameters:

- Imaging format: 1.1″, compatible with high-pixel industrial cameras;

- Focal length: 35mm, diagonal field of view 28°, horizontal field of view 23°, precise focusing;

- Resolution: 2000 10MP high-definition imaging with no noise;

- Aperture: F2.8~22, wide exposure adjustment range, strong imaging stability;

- Distortion rate: ≤0.02%, industry-leading ultra-low distortion level;

- Minimum object distance (M.O.D.): 0.2m, suitable for medium-distance precision inspection;

- Interface type: C-Mount, compatible with mainstream FA systems.

Core advantages: Ultra-low distortion rate of 0.02% ensures image geometric accuracy; 20MP high resolution accurately reproduces subtle features; designed specifically for optical character recognition (OCR) and precision surface inspection; stable enough for 24-hour continuous industrial operation.

Suitable scenarios:

- Precision measurement of electronic component pin dimensions;

- PCB board pad character recognition (OCR) and spacing detection;

- Surface defect screening of automotive micro-parts (such as screws and clips);

- Precision instrument scale reading and data acquisition.

20-35mm-20MP-C-mount-low distortion FA lens-lens

3. Zoom Lens (C157511715A8): A Dynamic Solution for Flexible Multi-tasking Scenarios

With a 15-75mm zoom focal length and infrared correction technology, this lens allows for flexible switching between detection distance and field of view, adapting to mixed multi-tasking scenarios.

Key Technical Parameters:

- Imaging Format: 1/1.7″, compatible with mainstream sensors such as IMX324 and IMX226;

- Focal Length: 15-75mm, horizontal field of view 6°~26°, wide zoom range;

- Resolution: 8 megapixels, meeting medium to high-definition inspection needs;

- Aperture: F1.5, large aperture design, strong low-light sensitivity;

- Distortion Rate: ≤6.1%, stable imaging during zooming;

- Minimum Object Distance (M.O.D.): 1.5m, supporting medium to long-distance detection;

- Interface Type: C-Mount, infrared (IR) correction, supports day/night switching;

- Aperture Control: DC automatic aperture, adaptable to dynamic light changes.

Key Advantages: The zoom focal length can be adjusted as needed, allowing detection of targets of different distances and sizes without changing the lens; F1.5 large aperture + Infrared correction technology ensures clear imaging even in low-light and nighttime conditions, with automatic aperture adapting to light fluctuations.

Suitable Scenarios:

- Intelligent Transportation Systems (ITS) vehicle license plate recognition and violation capture;

- Long-distance barcode/QR code recognition in logistics and warehousing;

- Alternating multi-part detection on large equipment (e.g., machine tools, production lines);

- Security monitoring and anomaly detection in outdoor industrial scenarios (e.g., factory perimeter walls, transport channels).

IR-corrected-ITS-traffic-C-mount-CCTV-lens

4. High-Definition FA Lens (C5011028M20): A Reliable Platform for Long-Distance Precision Inspection

50mm telephoto design with ultra-low distortion, specifically designed for medium- to long-distance precision inspection and recognition scenarios, balancing accuracy and detection distance.

Core Technical Parameters:

- Imaging Format: 1.1″, compatible with high-pixel industrial cameras;

- Focal Length: 50mm, diagonal field of view 20°, horizontal field of view 16°, focusing on distant targets;

- Resolution: 2000 10MP resolution, high-definition detail reproduction;

- Aperture: F2.8~22, high image contrast, strong anti-interference capability;

- Distortion rate: ≤0.04%, precision measurement-grade distortion control;

- Minimum object distance (M.O.D.): 0.3m, supports precise focusing at medium to long distances;

- Interface type: C-Mount, compatible with industrial automation systems.

Core advantages: Long focal length allows for precision inspection without contacting the target; 20MP high resolution + 0.04% low distortion rate ensures both inspection distance and accuracy; manual adjustment design adapts to stable inspection scenarios.

Suitable scenarios:

- Long-distance QR code recognition and data traceability on production lines;

- Surface defect inspection of large components (such as car bumpers, engine housings);

- Material positioning and status monitoring of high-altitude equipment (such as conveyor belts, shelves);

- Long-distance dimensional verification of precision molds.

50mm-C-mount Machine Vision FA lens

5. IR Lens (C095011816A3): A Master at Detecting Hidden Defects Through Surface Interference

Infrared correction technology combined with a zoom focal length allows it to penetrate light interference and surface reflections, making it a core piece of equipment for day and night use and inspection in complex environments.

Key Technical Parameters:

- Imaging Format: 1/1.8″, compatible with sensors such as IMX185 and IMX385;

- Focal Length: 9-50mm, horizontal field of view 8.6°~46°, zoom adaptable to various scenarios;

- Resolution: 3 megapixels, meeting the needs of high-definition monitoring and inspection;

- Aperture: F1.6, clear imaging in low-light environments;

- Distortion Rate: -19.1%~-0.9%, stable performance during zooming;

- Minimum Object Distance (M.O.D.): 0.1m, supports flexible switching between near and far distances;

- Interface Type: C-Mount, infrared (IR) correction, supports day/night switching;

- Aperture Control: DC automatic aperture, adaptable to dynamic changes in light.

Core Advantages: Infrared correction technology can penetrate surface reflections, fog, and other interference, enabling uninterrupted day and night detection; 9-50mm The zoom focal length adapts to different detection ranges, and the automatic aperture eliminates the need for manual adjustment, making it suitable for complex lighting environments.

Suitable Scenarios:

- Nighttime production line defect detection and safety monitoring;

- Surface defect screening of highly reflective materials (such as metal and glass);

- Outdoor/semi-outdoor security monitoring (such as factory perimeters and parking lots);

- Packaging damage detection in cold chain logistics freezers (resistant to low-temperature environments).

C-mount IR corrected CCTV lens

5 Models Core Specifications Comparison Table

| Comparison Dimension | Wide-Angle Lens | Ultra-Low Distortion Lens | Zoom Lens | FA Lens | IR Lens |

| Image Format | 1.1″ | 1.1″ | 1/1.7″ | 1.1″ | 1/1.8″ |

| Focal Length Range | 6mm (Fixed) | 35mm (Fixed) | 15-75mm (Zoom) | 50mm (Fixed) | 9-50mm (Zoom) |

| Resolution | 20MP | 20MP | 8MP | 20MP | 3MP |

| Maximum Aperture | F1.8 | F2.8 | F1.5 | F2.8 | F1.6 |

| Distortion Rate | ≤2.5% | ≤0.02% | ≤6.1% | ≤0.04% | -19.1%~-0.9% |

| Minimum Object Distance (M.O.D.) | 0.1m | 0.2m | 1.5m | 0.3m | 0.1m |

| Mount Type | C-Mount | C-Mount | C-Mount (IR Corrected) | C-Mount | C-Mount (IR Corrected) |

| Aperture Control | Manual | Manual | DC Auto | Manual | DC Auto |

| Core Tags | Wide FOV, High Definition | Ultra-Low Distortion, Precision Measurement | Zoom, Low-Light, ITS | Telephoto, High Precision | IR, Zoom, Day-Night Use |

How to Choose a Lens Based on Industrial Needs? 3 Key Decision Factors

In industrial scenarios, lens selection directly impacts image quality, system stability, and long-term operating costs. The following three key factors can quickly identify a suitable solution, balancing accuracy, compatibility, and stability:

1. Resolution and Pixel Requirements: Matching the Camera Sensor

- Core Logic: Lens pixels ≥ camera pixels, image format compatibility, avoiding wasted performance or insufficient accuracy.

- High-precision inspection (micron-level defects/measurement): Select a 20MP lens (e.g., TOWIN C3511028M20, C5011028M20), compatible with a 1.1″ large sensor;

- Routine inspection (appearance/integrity screening): 8MP or 3MP lenses (e.g., C157511715A8, C095011816A3) are sufficient;

- Crucial: The lens imaging format (1.1″, 1/1.7″, etc.) must be consistent with the camera sensor.

2. Working distance and installation space: Adapt to site conditions

- Compact space/close-range inspection (≤0.3m): Select a short focal length, small-volume lens (e.g., C0611018M20, 6mm fixed focal length, M.O.D. 0.1m);

- Medium-to-long-range inspection (≥1.5m): Telephoto/zoom lens (e.g. C157511715A8 (15-75mm zoom);

- Large-area inspection: Wide-angle lens (C0611018M20, 105° horizontal field of view); Small-area precision inspection: Narrow field of view telephoto lens (C5011028M20, 16° horizontal field of view).

3. Environmental adaptability: Industrial-grade stability assurance

- Dust/humidity: Select sealed/IP67 protected lens;

- High and low temperatures (-20℃~60℃): TOWIN full series wide temperature adaptability, no additional equipment required;

- Vibration/high-speed scenes: Metal housing + integrated lens barrel design (such as C-Mount series), anti-vibration and anti-blur;

- Low light/high reflectivity: Large aperture (F1.5-F1.8) + infrared correction lens (such as C157511715A8), reducing light interference.

IR 12MP Low Distortion Machine Vision Lens

TOWIN The Perfect Fusion of Optics and Performance

TOWIN is a globally trusted brand in machine vision lenses, offering high-precision, low-distortion imaging with all-scenario adaptability. It features remarkable optical innovation, ultra-HD quality, robust industrial durability, and multi-device compatibility, catering to needs from basic to high-end precision manufacturing. Its high-transmittance optical materials, integrated sealing structure, and intelligent optical correction technology offer excellent anti-interference, durability, and stability, making it the best optical solution for vision systems in industrial automated production lines.

FAQs

Q1: How do I determine if the resolution of a TOWIN lens matches my camera?

A: The core principle is that “lens pixels ≥ camera sensor pixels, and the imaging format is compatible.” It’s also necessary to confirm that the lens’s imaging format matches the camera sensor size to avoid issues such as image cropping and increased distortion.

Q2: How should I choose the focal length of a TOWIN lens for different industrial scenarios?

A: Focal length selection should consider both working distance and inspection range: ① For close-range, large-area inspection, choose a short focal length wide-angle lens; ② For medium-to-long-range, precise inspection, choose a telephoto or zoom lens; ③ For measuring the minute dimensions of precision parts, choose a 35mm, 50mm, or other medium-to-long focal length low-distortion lens.

Q3: Which type of TOWIN lens should I prioritize for low-light or nighttime scenes?

A: Prioritize lenses with a large aperture and infrared correction. A large aperture increases light intake in low-light environments, and infrared correction ensures consistent imaging day and night, avoiding blurry images and excessive noise.

Q4: Are TOWIN C-Mount lenses compatible with all industrial cameras?

A: TOWIN C-Mount lenses are compatible with most mainstream C-mount industrial cameras on the market, but please ensure that the camera sensor size does not exceed the lens’s imaging format. If the camera has a CS mount, a CS-to-C adapter ring is required; otherwise, focusing may be inaccurate. For specific compatibility information, please refer to the product manual or consult technical personnel.

Conclusion

Through the above product examples, TOWIN demonstrates its relentless pursuit of innovation in machine vision optics technology and adaptation to industrial scenarios. From standard inspection lenses for basic production lines to ultra-low distortion measurement lenses for high-precision manufacturing, TOWIN lenses can meet the needs of diverse users. Whether you are seeking a cost-effective standardized solution or have customized special optical requirements, TOWIN Machine Vision Lenses offer accurate, reliable, and scenario-appropriate options!