How to choose the right lens for 3D laser scanning

Waterproof IP67 lenses for underwater inspection

01/23/2026

Wide-angle CS-Mount lenses for parking systems

01/25/2026Table of Contents

- Introduction

- 1. Pair the Lens with Your Scanner’s Exact Laser Wavelength

- 2. Define Your Working Distance & Field of View First

- 3. Prioritize Resolution & Pixel Density for Precision Scans

- 4. Choose a Lens with Sufficient Depth of Field for Irregular Surfaces

- 5. Minimize Optical Distortion for Accurate Point Cloud Reconstruction

- 6. Select Lens Materials & Coatings for Your Laser & Environment

- 7. Confirm Full Hardware Compatibility

- 8. Engineer the Lens for Your Scanning Environment

- 9. Match the Lens to Your 3D Laser Scanning Technology

- FAQs

- Final Thoughts

Key Takeaways

- Pair your lens with your 3D scanner’s specific laser wavelength to eliminate light loss and preserve measurement precision—this is the single most critical step.

- Nail down your working distance (WD) and field of view (FOV) first: these two metrics directly determine the ideal lens focal length and type (short, medium, telephoto, telecentric).

- Prioritize minimal optical distortion (≤0.1% for metrology-grade scans) and ample depth of field (DOF) when scanning curved, stepped, or textured surfaces.

- Choose lens materials and coatings engineered for your laser power and scanning environment—AR coatings for laser wavelengths and IP-rated protection are non-negotiable for industrial use.

- Match your lens to your scanner’s core technology (triangulation, ToF, phase-shift)—each method has unique optical needs for optimal point cloud quality.

- Confirm full hardware compatibility (mount type, flange distance) with your scanning camera/sensor; a great lens is useless if it doesn’t fit or connect properly.

Introduction

3D laser scanning creates accurate point clouds and 3D models by capturing laser light reflected off target surfaces—and the lens is the backbone of this optical process. A poorly matched lens doesn’t just reduce scan quality: it causes light attenuation, distorted point clouds, lost fine details, and inaccurate dimensional measurements, even with a top-tier scanner. This guide breaks down the 9 essential considerations for choosing an industrial lens that aligns with your 3D laser scanning goals, from micro-precision part inspection to long-range outdoor spatial scanning.

1. Pair the Lens with Your Scanner’s Exact Laser Wavelength

Every 3D laser scanner operates with a fixed laser wavelength (visible red or near-infrared/NIR) for emission and detection. For sharp, noise-free scans, your lens must deliver high transmittance at this exact wavelength—generic lenses will filter out critical laser light, lowering signal-to-noise ratio (SNR) and creating grainy, unreliable point clouds.

Laser Wavelength & Corresponding Lens Requirements

| Laser Wavelength | Primary Scanning Use Case | Lens Optical Specifications |

| 635nm/650nm (red visible) | Benchtop precision scanning for small parts (electronics, medical components) | BK7/SF11 optical glass + AR coating optimized for 600–700nm |

| 905nm (NIR) | Mid-range industrial part scanning (triangulation/ToF systems) | NIR-enhanced glass + AR coating for 850–950nm |

| 1550nm (NIR) | Long-range scanning & eye-safe industrial laser systems | Specialized IR glass (e.g., CaF2) + AR coating tailored to 1500–1600nm |

Critical Tip: Never use a standard visible-light lens for NIR 3D scanning (905nm/1550nm). These lenses have minimal transmittance for near-infrared wavelengths and will cripple your scan accuracy and consistency.

2. Define Your Working Distance & Field of View First

Your scanner’s working distance (the gap between the lens and the target surface) and field of view (the total area the lens can capture in a single scan) are the foundation of lens focal length selection. Focal length and FOV have an inverse relationship: shorter focal lengths deliver a wider FOV (perfect for close-up scans of large surfaces), while longer focal lengths offer a narrower FOV (ideal for long-distance scans of small, precise features).

Focal Length Selection for Common 3D Scanning Scenarios

- Macro/Close-Range Scanning (WD < 100mm): Small, high-precision parts (semiconductors, micro-molds) → 2.8mm–12mm short-focal lenses. These deliver a tight FOV with high pixel density, so you never lose tiny surface details or micro-features.

- Mid-Range Industrial Scanning (WD 100mm–1m): Standard manufacturing parts (automotive components, tooling, plastic molds) → 16mm–50mm medium-focal lenses. This is the most versatile range for everyday industrial 3D scanning, balancing FOV and precision.

- Long-Range Scanning (WD > 1m): Large equipment, aerospace parts, or industrial machinery → 75mm–200mm long-focal/telephoto lenses. These maintain sharp precision even when scanning from a distance, avoiding blurry or stretched point clouds.

- Large-Scale Spatial Scanning (WD > 5m): Construction sites, shipbuilding, outdoor structural scanning → wide-angle long-focal lenses. They strike the perfect balance between a broad FOV (for large surfaces) and long-distance scanning accuracy.

Quick Calculation for Exact Focal Length:

Use this formula to find your ideal focal length—you’ll need your scanner’s sensor size (provided by the manufacturer) for the math:

Focal Length (f) = (Sensor Size × Working Distance) ÷ Field of View

Sensor size = the width/height/diagonal of your scanning camera’s image sensor (e.g., a 1/1.8” sensor = 7.18mm × 5.32mm width/height).

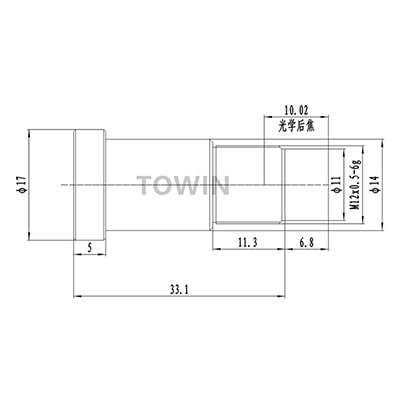

Industrial lens 50mm C-mount FA lens

3. Prioritize Resolution & Pixel Density for Precision Scans

3D scan accuracy hinges on two key optical traits: lens optical resolution (its ability to distinguish fine details) and pixel density (how well the lens pairs with your scanner’s camera sensor). A high-megapixel sensor (12MP, 20MP, or more) paired with a low-resolution lens is a waste of hardware: it produces soft, blurry point clouds and erases critical small features like threads, pinholes, and surface textures.

Resolution Rules for 3D Laser Scanning Lenses

- Optical Resolution: Measured in line pairs per millimeter (lp/mm). Choose ≥100 lp/mm for metrology-grade scanning (sub-millimeter precision) and ≥50 lp/mm for general industrial QC and 3D modeling.

- Sensor-Lens Compatibility: Never use a lens with a lower resolution rating than your scanner’s sensor. A 5MP lens on a 12MP sensor will underperform and leave your scanner’s full capability untapped.

- Pixel Size Optimization: For micro-scanning (e.g., semiconductor or medical device parts), select a lens designed for small sensor pixel sizes (<3μm). This prevents undersampling, which leads to sparse, incomplete point clouds.

4. Choose a Lens with Sufficient Depth of Field for Irregular Surfaces

Nearly all 3D scanning targets are non-flat: curved plastics, stepped metal parts, textured composites, and complex geometric shapes are the norm in industrial settings. A lens with insufficient DOF (the range of distances where the target stays in sharp focus) will only focus on a small section of the surface—every other area will blur, leading to missing or distorted point cloud data.

What’s the Best Lens for Maximum DOF in 3D Scanning?

Object-side telecentric lenses are the industry gold standard for high-precision 3D laser scanning—and their unbeatable DOF is the biggest reason why. They also offer game-changing benefits for industrial scanning:

- Constant magnification, no matter the working distance (no size distortion for curved or uneven surfaces).

- Near-zero perspective distortion (critical for accurate dimensional measurements and QC).

- Immunity to off-axis light errors, which cuts down on point cloud noise and grain.

Telecentric lenses are non-negotiable for metrology-grade scanning (CNC part inspection, high-tolerance reverse engineering). For general industrial scanning with flat or mildly curved surfaces, extended-DOF fixed-focal machine vision lenses are a cost-effective alternative that still delivers great results.

5. Minimize Optical Distortion for Accurate Point Cloud Reconstruction

Optical distortion (barrel, pincushion, or tangential) warps the image the lens captures—and that warp translates directly to flawed point clouds. A distorted lens can turn a circular hole into an ellipse, stretch a straight edge into a curve, or shift dimensions by millimeters—disastrous for QC, metrology, and reverse engineering where precision is everything.

Optical Distortion Tolerances by Scanning Application

- Metrology/Calibration-Grade Scanning: ≤0.1% optical distortion (only telecentric or ultra-precision machine vision lenses meet this strict standard).

- Industrial Quality Control: ≤0.5% distortion (high-performance fixed-focal machine vision lenses work perfectly here).

- General 3D Modeling/Reverse Engineering: ≤1% distortion (affordable industrial lenses—software calibration can correct minor distortion for these use cases).

Pro Tip: Even the best lenses have tiny amounts of distortion. Always run a camera-lens calibration with your scanner’s software before your first scan. This fine-tunes the lens to your sensor, corrects minor distortion, and locks in maximum accuracy for every scan after.

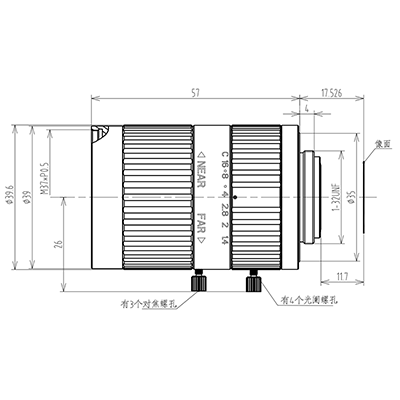

6mm Wide-angle C-Mount Machine Vision lens

3D laser scanning lenses face harsh conditions: laser energy exposure, factory dust, temperature fluctuations, outdoor humidity, and physical wear and tear. The right optical materials and coatings don’t just boost performance—they protect your lens and ensure long-term reliability in industrial settings.

Optical Materials for 3D Laser Scanning Lenses

- BK7/SF11 Optical Glass: The go-to for visible (635/650nm) and 905nm NIR scanning. It’s durable, cost-effective, and delivers high transmittance for most industrial laser wavelengths.

- Specialized IR Glass (CaF2, ZnSe): Mandatory for 1550nm NIR long-range scanning. BK7 glass has poor transmittance at 1550nm, so IR-specific glass is the only option for clear, accurate scans.

- Anti-Laser Irradiation Glass: For high-power laser scanners (≥100mW). This material prevents lens aging, cracking, or discoloration from prolonged laser exposure—essential for 24/7 industrial scanning operations.

Must-Have Optical Coatings for Industrial 3D Scanning

- Wavelength-Matched Anti-Reflective (AR) Coating: Non-negotiable. This coating cuts down on light reflection at the lens surface, boosts transmittance for your scanner’s exact laser wavelength, and eliminates stray light (the main cause of point cloud noise). Never use a generic AR coating—always pick one tailored to your laser’s wavelength.

- Hard Coat (HC)/Anti-Scratch Coating: Ideal for factory floors, construction sites, or outdoor scanning. It protects the lens from dust, debris, and minor physical damage that can scratch the glass and ruin scan quality.

- Water/Dust-Repellent Coating: For outdoor or harsh industrial environments. Pair it with an IP-rated lens housing to repel moisture, oil, and dust—keeping your lens clean and performing at its best without constant maintenance.

7. Confirm Full Hardware Compatibility

A top-of-the-line telecentric lens is useless if it doesn’t fit your scanner or connect to your camera. Before you buy, verify three critical hardware compatibility factors—they’re the difference between a seamless setup and a frustrating one.

Lens Mount Type

Industrial 3D scanning uses a small set of standardized mounts (90% of scanners/cameras use these):

- C-Mount: The industry standard for machine vision and 3D laser scanning. It’s compatible with nearly all industrial scanners and offers a secure, stable connection.

- CS-Mount: For compact handheld scanners and small-form-factor industrial setups. Note: A C-mount lens fits a CS-mount camera with a 5mm spacer, but a CS-mount lens will not fit a C-mount camera.

- F-Mount/S-Mount: F-mount for high-resolution, long-range scanning; S-mount for micro-scanning and ultra-compact setups.

Flange Distance

Flange distance is the gap between the lens mount and the scanner’s image sensor. An incorrect flange distance causes permanent out-of-focus issues—no amount of manual focusing will fix it. Always match the lens’s flange distance to your scanner/camera’s published specifications (provided by the manufacturer).

Form Factor & Weight

For handheld 3D scanners or robotic scanning cells, choose a small, lightweight lens to avoid mechanical interference, balance issues, or added strain on robotic arms. For stationary benchtop scanners, form factor and weight are far less critical—you can prioritize optical performance over size.

8. Engineer the Lens for Your Scanning Environment

3D scanning happens everywhere: clean labs, dusty factory floors, rainy construction sites, and sterile clean rooms. Your lens must be built to withstand your specific environment to avoid performance drops or premature failure. Below’s how to match your lens to your workspace:

| Scanning Environment | Non-Negotiable Lens Features |

| Industrial Factory Floor (dust, vibration, temperature swings) | IP65/IP67 waterproof/dustproof housing, anti-vibration lens mount, wide operating temperature range (-10°C to 60°C) |

| Outdoor (sunlight, humidity, rain, wind) | IP67/IP68 protection, UV-resistant coating, lens sunshade (blocks stray sunlight), temperature-stabilized optical glass |

| Clean Room (semiconductor/medical manufacturing) | Low-particle, glue-free construction, anti-static coating, easy-to-clean glass surfaces (no crevices for dust buildup) |

| Benchtop/Lab (controlled conditions) | Standard industrial machine vision lens (no special environmental protection needed) |

9. Match the Lens to Your 3D Laser Scanning Technology

Not all 3D laser scanners work the same way—triangulation, ToF, and phase-shift scanners use distinct light detection methods, and each has unique optical requirements. Pairing your lens with your scanner’s core technology ensures you capture the sharpest, most accurate point clouds possible.

1. Triangulation Scanning (Most Common Industrial Precision Scanning)

- Core Needs: High resolution, minimal distortion, ample DOF, wavelength-matched transmittance.

- Best Lens: Object-side telecentric lenses (metrology-grade) or high-performance fixed-focal machine vision lenses (general industrial use).

2. Time-of-Flight (ToF) Scanning (Mid/Long-Range Large-Scale Scanning)

- Core Needs: Large aperture (low f-number: f/1.4–f/2.8) for high light sensitivity, wide FOV, stable long-distance performance.

- Best Lens: Wide-angle long-focal lenses or ToF-optimized machine vision lenses (low noise, high SNR for clear point clouds at range).

3. Phase-Shift Scanning (Ultra-High-Precision Static Scanning)

- Core Needs: Ultra-low distortion (≤0.1%), maximum optical resolution, stable magnification, wavelength-matched AR coating.

- Best Lens: Metrology-grade object-side telecentric lenses—the only lens type that delivers the sub-micron precision phase-shift scanning requires.

4. Handheld 3D Scanning (Portable Industrial/Field Scanning)

- Core Needs: Compact, lightweight, extended DOF, IP-rated environmental protection, wavelength-matched transmittance.

- Best Lens: Miniature fixed-focal machine vision lenses or compact telecentric lenses (for handheld metrology-grade scanners).

5. Additional Practical Tips for Lens Selection

- Balance Precision and Cost: Telecentric lenses are the best for high-precision scanning, but they’re more expensive. For general 3D modeling or low-tolerance QC, extended-DOF fixed-focal machine vision lenses (paired with software calibration) offer great value and performance.

- Stick to Industrial-Grade Brands: Avoid consumer photography lenses—they’re optimized for visible-light photos, not laser scanning, and lack industrial durability. Choose brands specializing in machine vision and 3D scanning: Computar, Tamron, Edmund Optics, Navitar, and Opto Engineering are all trusted industry names.

- Consider Custom Lenses for Unique Scenarios: If you’re scanning ultra-small parts, using a 1550nm long-range outdoor scanner, or working with a custom-built scanning system, partner with a professional lens manufacturer for a custom optical solution. They’ll engineer a lens to your exact scanner specifications and use case.

- Calibrate Regularly: Don’t just calibrate your lens once—re-run the camera-lens calibration every few months (or after moving the scanner) to correct for minor shifts and keep your scans accurate over time.

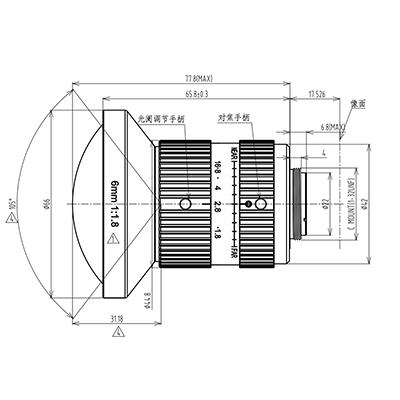

6mm Low Distortion Industrial Lens

FAQs

Q1: Why are object-side telecentric lenses the best for high-precision 3D laser scanning?

A1: Object-side telecentric lenses deliver four unbeatable benefits for high-precision scanning: near-zero optical distortion, constant magnification regardless of working distance, an ultra-large depth of field, and immunity to off-axis light errors. These traits are critical for generating accurate, undistorted point clouds and sub-millimeter/micron-grade dimensional measurements—no other lens type can match this performance for metrology and high-tolerance QC.

Q2: Can I use a consumer photography lens for 3D laser scanning?

A2: No—never use a consumer photography lens for industrial 3D laser scanning. Consumer lenses are optimized for visible-light photography, not laser wavelengths, and they have high optical distortion, poor DOF control, and no industrial environmental protection. They’ll cause severe light attenuation, grainy point clouds, and inaccurate measurements—even for basic 3D modeling. Only use industrial machine vision or 3D scanning-specific lenses.

Q3: How do I calculate the focal length I need for my scan?

A3: Use the simple focal length formula: Focal Length (f) = (Sensor Size × Working Distance) ÷ Field of View. You’ll need your scanner’s sensor size (width/height/diagonal—provided by the manufacturer) and your desired working distance/FOV. For example: a 1/1.8” sensor (7.18mm width) with a 200mm working distance and 100mm FOV (width) needs a ~14.4mm focal length lens.

Q4: Can I fix lens distortion with 3D scanning software?

A4: Modern 3D scanning software includes lens calibration tools that can correct minor optical distortion (≤1%) (barrel or pincushion). However, software cannot fix severe distortion (>1%) or fundamental optical issues like light attenuation from a wavelength-mismatched lens. Always prioritize a low-distortion lens first—use software calibration only for fine-tuning, not as a fix for a poor lens choice.

Final Thoughts

Selecting the right lens for 3D laser scanning boils down to one simple principle: align the lens’s optical performance and durability with your specific scanning needs, environment, and hardware. Start by locking in your core parameters—laser wavelength, working distance, FOV, and precision tolerance—then build your lens choice around those metrics. For metrology-grade scanning, an object-side telecentric lens is the only option; for general industrial use, an extended-DOF fixed-focal machine vision lens offers the best balance of performance and cost.

Don’t skip the small steps: verify hardware compatibility, choose wavelength-matched materials and coatings, and calibrate your lens before your first scan. These actions ensure your scanning system is reliable, accurate, and built to perform in industrial settings.