Spherical vs Aspherical Lenses: Balancing image quality and manufacturing cost

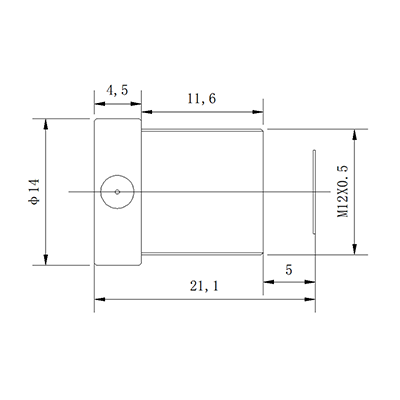

Fixed focal length C-mount industrial lenses

02/07/2026Table of Contents

Key Takeaways

- Spherical lenses have uniform curvature, lower cost but inherent spherical aberration; aspherical lenses correct aberration via variable curvature for better image quality but higher production costs.

- Spherical aberration is the core cause of image quality differences, which aspherical lenses mitigate by optimizing curvature distribution.

- Aspherical lens costs depend on craftsmanship (molding, grinding/polishing, precision coating) and precision requirements, with obvious cost gradients between processes.

- Balancing strategy: Align lens type with application scenarios, prioritize core needs, and optimize via process selection and batch production.

Introduction

In industrial optics, machine vision, photography, and automotive lighting fields, lenses are core components determining image output effects. Spherical vs Aspherical Lenses, as two mainstream types, show obvious trade-offs between image quality and manufacturing cost. For overseas buyers, manufacturers, and R&D teams, how to select the right lens type based on project budgets, performance requirements, and application scenarios to achieve the optimal balance between quality and cost has become a key decision-making point. This article will deeply analyze the differences between the two lenses, explore cost-quality balance logic, and provide practical reference for industrial optical applications.

Technical Principles: Curvature Design Determines Optical Performance

The fundamental difference between Spherical vs Aspherical Lenses lies in curvature design, which directly affects light refraction paths and final optical performance.

Spherical Lenses

- Curvature feature: The surface is a part of a sphere, with uniform curvature radius at all points on the surface.

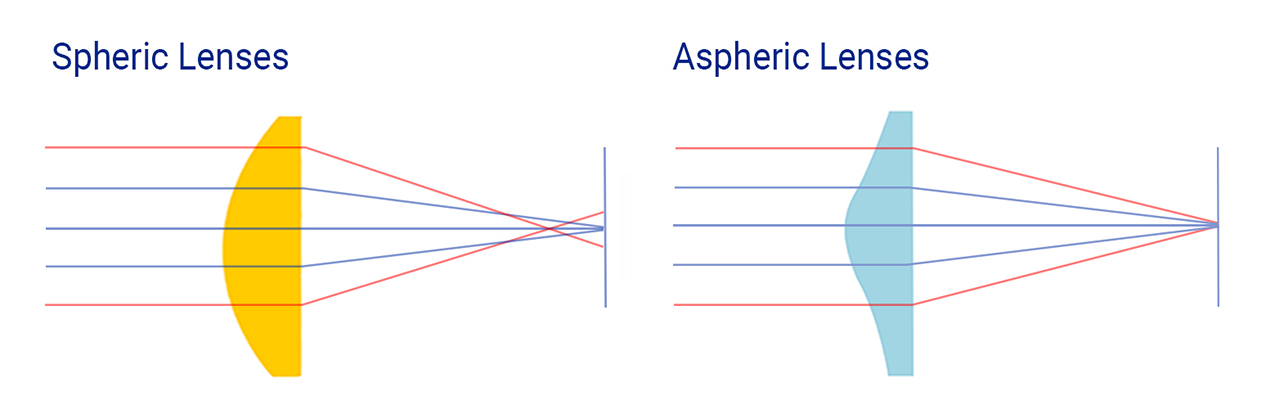

- Optical principle: Light rays pass through the spherical surface and converge at a focal point, but due to the limitation of uniform curvature, light from the edge and center cannot converge at the same point.

- Advantage: Simple design, mature processing technology, and low difficulty in mold or tooling manufacturing.

Aspherical Lenses

- Curvature feature: The surface curvature radius changes continuously along the optical axis, and the shape is designed according to specific mathematical equations (such as quadratic curves, high-order polynomials).

- Optical principle: By optimizing the curvature distribution, it adjusts the refraction angle of light rays at different positions, making edge and center light converge at the same focal point.

- Advantage: Effectively corrects optical aberrations, reduces lens volume, and improves light transmittance and resolution.

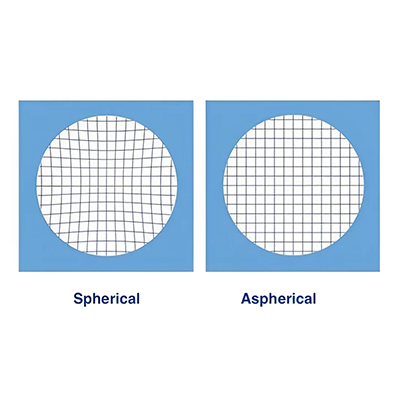

Spherical vs Aspherical Lenses

Core Source of Image Quality Differences: Impact of Spherical Aberration and Correction Logic of Aspherical Lenses

Spherical aberration is the primary factor leading to image quality gaps between the two lenses, and the correction logic of aspherical lenses directly addresses this pain point.

Spherical Aberration and Its Impact

- Definition: When parallel light rays pass through a spherical lens, the central light converges closer to the lens, while the edge light converges farther away, resulting in blurred images, halos, and reduced contrast.

- Image defects: Reduced sharpness of the target object, distorted details, and inability to meet high-precision imaging requirements (such as machine vision measurement, medical imaging).

- Compensation method for spherical lenses: Use multiple spherical lenses to form a lens group for aberration correction, which increases volume, weight, and assembly cost.

Correction Logic of Aspherical Lenses

- Curvature optimization: The edge curvature of the aspherical surface is appropriately flattened to reduce the refraction angle of edge light, making it converge with central light at the same focal point.

- Multi-aberration correction: While eliminating spherical aberration, it can also suppress coma, astigmatism, and field curvature to a certain extent, improving overall imaging uniformity.

- Simplified lens structure: A single aspherical lens can replace multiple spherical lens groups, reducing light loss caused by multiple interfaces and improving light transmittance.

Image Quality Comparison Table

| Evaluation Indicator | Spherical Lenses | Aspherical Lenses |

| Spherical Aberration | Obvious, needs lens group compensation | Effectively corrected, low aberration |

| Image Sharpness | General, edge details blurred | High, full-field clear details |

| Contrast & Brightness | Low, easy to have halos | High, uniform brightness distribution |

| Lens Volume | Large (lens group required) | Small (single lens optional) |

Core Source of Manufacturing Cost Differences: Process Grading and Cost Threshold of Aspherical Lenses

The cost gap between the two lenses is mainly caused by the complexity of aspherical lens processing, and different processes lead to obvious cost gradients.

Manufacturing Process & Cost of Spherical Lenses

- Processing steps: Molding, grinding, polishing, coating. The process is mature and automated production is easy to realize.

- Cost drivers: Low raw material waste rate, simple mold design, short processing cycle, and low labor skill requirements.

- Cost advantage: Mass production cost is 30%-60% lower than that of aspherical lenses of the same specification.

Process Grading & Cost of Aspherical Lenses

| Processing Process | Precision Level | Cost Level | Application Scope |

| Injection Molding | General (±0.01mm) | Low-Medium | Consumer electronics, automotive lighting, low-precision optics |

| Precision Grinding & Polishing | High (±0.001mm) | Medium-High | Machine vision, industrial detection, medical equipment |

| Single-Point Diamond Turning | Ultra-High (±0.0001mm) | High | Aerospace, precision measurement, high-end optics |

Key Cost Thresholds of Aspherical Lenses

- Mold cost: The aspherical mold requires high-precision processing, and the mold cost is 5-10 times that of spherical lenses; it is only cost-effective for mass production (batch > 100,000 pieces).

- Processing difficulty: The variable curvature surface is difficult to grind and polish, requiring professional equipment and skilled technicians, which increases labor and time costs.

- Coating cost: To match high imaging quality, aspherical lenses often need high-transmittance, anti-reflection multi-layer coatings, with coating cost 2-3 times that of spherical lenses.

Application Scenarios: Select Lens Type Based on Requirements

The selection of Spherical vs Aspherical Lenses should be based on the core needs of the scenario, avoiding over-pursuing quality or blindly controlling costs.

Scenarios Suitable for Spherical Lenses

- Low-precision lighting: Street lamps, ordinary flashlights, decorative lighting, where image quality requirements are low and cost control is the core.

- Entry-level optical equipment: Entry-level cameras, toy lenses, simple magnifiers, with low product positioning and sensitive to cost.

- Large-batch standard products: Industrial lenses with low precision requirements, where mature spherical lens production lines can reduce unit cost.

Scenarios Suitable for Aspherical Lenses

- High-precision machine vision: Automated inspection, semiconductor detection, where sharp imaging and low aberration are required to ensure measurement accuracy.

- Miniature optical devices: Smartphone lenses, portable scanners, where small size and light weight are required, and aspherical lenses can simplify the structure.

- High-end imaging equipment: Medical endoscopes, aerospace cameras, where full-field image uniformity and high resolution are core demands.

Core Balance Strategies Between Image Quality and Manufacturing Cost

Achieving balance requires comprehensive consideration of demand priority, process selection, and batch effects, and adopting targeted strategies.

- Prioritize demand sorting: Clarify core indicators (e.g., precision > cost for machine vision, cost > precision for ordinary lighting) and abandon non-core high-quality requirements.

- Optimize process selection: For medium-precision scenarios, choose injection-molded aspherical lenses to balance cost and quality; for small-batch high-precision needs, use grinding and polishing processes to avoid high mold costs.

- Hybrid lens design: Combine spherical and aspherical lenses: use aspherical for key aberration correction, spherical for light convergence, cutting costs.

- Batch optimization: For aspherical lens projects, negotiate with manufacturers to determine the minimum economic batch, and reduce unit cost through mass production.

- Cost control in coating: Select coating schemes based on scenarios—use ordinary anti-reflection coatings for general scenarios, and high-end coatings only for core high-precision products.

Balance Implementation Cases in Different Industrial Optical Scenarios

| Industrial Scenario | Lens Selection | Balance Strategy | Implementation Effect |

| Automotive ADAS Cameras | Injection-molded aspherical lenses + spherical lens group | Use aspherical lenses to correct key aberrations; control cost via injection molding; auxiliary spherical lenses reduce the number of aspherical lenses. | Meets ISO 26262 safety standards; cost reduced by 25% compared to all-aspherical design. |

| 3C Product Visual Inspection | Precision ground aspherical lenses (1-2 pieces) + spherical lenses | High-precision aspherical lenses ensure edge detection accuracy; spherical lenses reduce assembly complexity and cost. | Detection accuracy reaches ±0.005mm; overall cost controlled within the budget. |

| Household Security Cameras | Spherical lens group (mainstream); aspherical lenses (high-end models) | Mass-produce spherical lenses for cost advantage; launch aspherical versions for high-end market to meet differentiated needs. | Mainstream models occupy 60% of the market; high-end models achieve 15% profit margin increase. |

FAQs

Q: Is the image quality of aspherical lenses definitely better than that of spherical lenses?

A: Not absolutely. For low-precision scenarios, the image quality of spherical lens groups can meet requirements; aspherical lenses show obvious advantages in high-precision, miniaturized, and full-field clear scenarios.

Q: When is the cost of aspherical lenses lower than that of spherical lens groups?

A: When the number of spherical lenses in the group exceeds 3-4 pieces (to correct aberration), the cost of a single aspherical lens is lower; mass production (batch > 100,000 pieces) can further reduce the unit cost of injection-molded aspherical lenses.

Q: What factors should be considered when customizing aspherical lenses for overseas projects?

A: Precision requirements, batch size, delivery cycle, and coating standards; it is recommended to choose manufacturers with mature mold opening and mass production capabilities to balance cost and lead time.

Q: Can spherical aberration be completely eliminated by aspherical lenses?

A: It can be effectively suppressed but not completely eliminated. For ultra-high-precision scenarios, further aberration correction is needed through multi-lens combination and optical design optimization.

Conclusion

The balance between Spherical vs Aspherical Lenses and image quality/manufacturing cost is not a “one-size-fits-all” choice, but a decision based on scenario demand positioning, batch scale, and budget constraints. Spherical lenses rely on mature processes to occupy cost advantages in low-precision, large-batch scenarios; aspherical lenses meet high-end optical needs through aberration correction and miniaturization advantages. For foreign trade businesses and industrial optical practitioners, clarifying core needs, optimizing process selection, and leveraging batch effects are the keys to achieving optimal cost-performance. Advancements in aspherical lens processing tech will narrow the cost gap, offering more flexible options for industrial optical uses.