What is an infrared correction lens?

CCTV lens 5.5mm F1.2 IR correct CS mount lens

08/11/2025

S-Mount Low Distortion Lens

08/12/2025Infrared (IR) technology has become indispensable in modern applications, from night-vision systems to industrial thermal imaging. However, traditional lenses struggle to maintain focus and clarity when transitioning between visible and infrared light wavelengths. This is where infrared correction lenses emerge as game-changers, offering unparalleled precision in multispectral imaging. But what is an infrared correction lens, and how does it work?

The Core Function: Correcting Chromatic Aberration Across Spectrums

An infrared correction lens minimizes chromatic aberration—distortion caused by differing light wavelengths focusing unevenly. While standard lenses are optimized for visible light (400–700 nm), infrared light (700 nm–1 mm) behaves differently, leading to blurry or misaligned images when both spectrums are used. Infrared correction lenses address this by incorporating specialized materials and coatings that align infrared and visible light wavelengths, ensuring sharp, accurate imaging even in low-light or thermal conditions.

How It Works:

- 1. Material Selection: Traditional lenses use glass, which has limited IR transmission. Infrared correction lenses often employ materials like germanium, chalcogenide glass, or zinc selenide, which offer high transparency across IR bands.

- 2. Multi-Element Design: By combining multiple lens elements with varying dispersive properties, these lenses compensate for wavelength-dependent focal shifts.

- 3. Anti-Reflective Coatings: Specialized coatings reduce glare and improve light transmission, enhancing contrast in both visible and IR spectrums.

CS mount wide angle lens IR corrected

5 Key Applications Redefining Industries

1. Surveillance and Security

- Infrared correction lenses are critical in CCTV and drone surveillance, enabling clear imaging day or night. For example, FLIR Systems, a leader in thermal imaging, integrates these lenses into cameras that detect heat signatures up to 300 meters away, even in complete darkness.

2. Astronomy and Space Exploration

- Telescopes like the James Webb Space Telescope rely on infrared correction to capture distant galaxies. By filtering out visible light interference, these lenses reveal celestial objects invisible to the naked eye.

3. Medical Imaging

- Infrared thermography is used to detect vascular diseases and inflammation. Correction lenses ensure accurate temperature readings by eliminating focal errors caused by skin emissivity variations.

4. Automotive Safety

- Advanced driver-assistance systems (ADAS) use IR-corrected lenses in lidar and night-vision cameras to identify pedestrians or obstacles in low-light conditions, reducing accident risks by up to 30% (according to a 2023 study by the Insurance Institute for Highway Safety).

5. Industrial Automation

- Robots and quality-control systems employ infrared correction to inspect products for defects. For instance, semiconductor manufacturers use IR lenses to detect cracks in silicon wafers with sub-micron precision.

C mount IR corrected CCTV lens

The Competitive Edge: Why Infrared Correction Matters

The demand for infrared correction lenses is surging, with the global market projected to reach $4.2 billion by 2030 (Grand View Research). Their ability to merge visible and IR data into a single, high-resolution image gives them an edge over traditional optics. Key advantages include:

- Enhanced Accuracy: Eliminates the need for separate IR and visible-light cameras, reducing system complexity.

- Cost Efficiency: A single infrared correction lens can replace multiple specialized lenses, lowering production costs.

- 24/7 Operation: Works seamlessly in daylight, darkness, or adverse weather conditions.

Challenges and Innovations

Despite their benefits, infrared correction lenses face hurdles. High-purity materials like germanium are expensive, and manufacturing requires precision tolerances below 1 micron. However, advancements in nanotechnology are driving costs down. For example, researchers at MIT have developed hybrid lenses combining polymer and metal substrates, reducing production costs by 40% while maintaining performance.Recommended Reading:IR Cut Filter S-Mount Lens

How to Choose the Right Infrared Correction Lens

Selecting the ideal lens depends on your application’s wavelength range, environmental conditions, and budget. Consider these factors:

- Wavelength Band: Ensure the lens supports your target IR spectrum (e.g., short-wave IR for industrial sensing or long-wave IR for thermal imaging).

- Aperture Size: Larger apertures gather more light but are costlier.

- Durability: Opt for weather-sealed lenses if used outdoors.

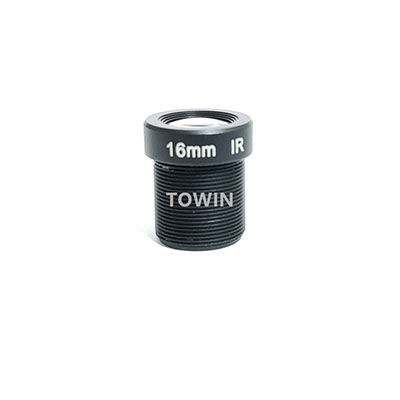

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

Conclusion

Infrared correction lenses are not just optical components—they’re enablers of innovation. By bridging the gap between visible and infrared light, they empower industries to see the unseen, operate in total darkness, and achieve unprecedented precision. As technology evolves, these lenses will play a pivotal role in shaping smart cities, autonomous vehicles, and next-gen medical diagnostics.