TOWIN M12 Lenses Comprehensive Analysis

8mm M12 CCTV lens IR corrected

12/25/2025

7 Top-Recommended CCTV Lenses for Garage Monitoring

12/26/2025Table of Contents

Introduction

With the rapid development of optical technology, TOWIN, with its innovative spirit and advanced manufacturing process, launched the M12 Lenses series. This series of lenses not only covers a variety of specifications and functions, but also features comprehensive upgrades in image quality, adaptability, and ease of use, aiming to meet the growing market demand. Whether in security monitoring, automotive imaging, or smart devices, the M12 Lenses series delivers outstanding performance. This article will delve into the core structure and optical principles of the M12 Lenses series, and provide users with selection criteria by analyzing core parameters, helping them find the most suitable lens for different application scenarios.

M12 Lenses Core Structure and Optical Principles

M12 Lenses Core Structure

| Aspect | Details | Technical Characteristics | Application Scenarios |

| Optical Components | Precision glass optical elements fixed by adhesive bonding | High stability, resistant to shock and vibration | Measurement, metrology, 3D stereo vision |

| Housing & Interface | Aluminum housing with M12脳0.5 threaded interface | Mechanical protection, optimized heat dissipation, strong compatibility | Camera and sensor integration |

| Special Optimization | Reinforced versions withstand 50g impact; liquid lenses enable electronic focusing | Adapt to harsh environments, fast auto-focus | Industrial automation, automotive electronics |

M12 Lenses Optical Principles

| Aspect | Details | Technical Characteristics | Application Scenarios |

| Basic Lens Combination | Doublet achromatic lenses, aspherical lenses, meniscus lenses | Correct chromatic aberration, optimize spherical and coma aberrations, improve resolution | Mobile phone lenses, machine vision |

| Liquid Lens Technology | Adjust focal length by applying voltage to alter liquid shape | Fast auto-focus, no mechanical wear, high light throughput | High-speed machine vision, autonomous driving |

| Aberration Correction & Optimization | Chromatic aberration correction, distortion control, resolution enhancement | Reduce residual chromatic aberration, minimize geometric distortion, support high-pixel sensors | Medical imaging, consumer electronics |

M12 Lenses Core Parameter Interpretation and Selection Criteria

In the M12 Lenses series, different models of lenses have their own unique core parameters, which directly determine the lens’s performance characteristics and applicable scenarios. Below, we will introduce five representative lenses in detail and analyze their parameters and selection criteria.

1. Low Distortion Lens Technology and Application Scenarios

Technical Characteristics:

- Low distortion lenses significantly reduce the curvature or distortion of image edges through special optical design (such as aspherical lenses, composite lenses) and material selection, ensuring the true reproduction of straight lines and geometric shapes. Their resolution and chromatic aberration control capabilities are superior to ordinary lenses, providing clearer edge details and accurate color reproduction.

Core Parameters:

- Distortion Rate: Typically below 1%, some high-end models can be controlled within 0.1%.

- Resolution: Supports high-pixel sensors (e.g., 5 megapixels, 1.4μm pixel size), meeting precision measurement needs.

- Total Optical Length (TTL) and Back Focal Length (BFL): Compact design (e.g., TTL≤15mm) suitable for embedded vision systems.

Application Scenarios:

- Industrial Measurement and Metrology: Such as 3D stereo vision, robot positioning, object tracking, requiring high geometric accuracy.

- Medical Imaging: Microscopes, endoscopes, and other equipment require clear, undistorted cell structures.

- Autonomous Driving: Lane recognition and obstacle detection rely on low-distortion images to reduce algorithm errors.

Selection Criteria:

- Prioritize lenses with a distortion rate ≤0.5% and resolution matching the sensor pixel size, such as the ruggedized blue M12 lens (withstands 50g impact, suitable for vibration environments).

Low distortion 5-Megapixel lens

2. Automotive Lens Compatibility and Performance Requirements

Technical Characteristics:

- Automotive lenses must withstand extreme environments (temperature -40℃~+85℃, humidity 95%RH), possess high shock resistance (e.g., 50g impact test) and dust and water resistance (IP6K9K). Optical design needs to optimize low-light performance (e.g., large F/2.0 aperture) and infrared transmittance (supporting 940nm infrared illumination).

Core Parameters:

- Aperture (F/#): F/2.0~F/2.8, balancing light intake and depth of field.

- Field of View (FOV): 60°~120° for forward-facing lenses, 180°~360° for surround-view lenses.

- Image Size: 1/2.7-inch to 1/1.8-inch sensors are required.

Application Scenarios:

- ADAS Systems: Forward-facing cameras (lane keeping assist, collision warning), side-facing cameras (blind spot monitoring).

- Autonomous Driving: Multi-camera fusion perception (e.g., Tesla’s 8-camera solution).

Selection Criteria:

- Select lenses that are AEC-Q100 certified and support ASIL functional safety levels, such as the M12 series liquid lens (fast electronic focusing, adaptable to dynamic scenarios).

IP67 M12 waterproof automotive lens

3. CCTV Lens (Security Lens) Adaptation and Image Quality Optimization

Technical Characteristics:

- Security lenses need to balance wide-angle coverage and telephoto detail, supporting zoom (e.g., 2.8-12mm zoom) or fixed focal length (e.g., 3.6mm fixed focal length). Optical design needs to suppress glare (e.g., anti-reflective coating) and improve low-light performance (e.g., F/1.4 large aperture).

Core Parameters:

- Focal Length Range: Fixed focal length lenses (2.8mm, 6mm) are suitable for indoor use; zoom lenses (2.8-12mm) are suitable for large-area outdoor monitoring.

- Aperture Type: Fixed aperture or automatic aperture (DC/Video driven), adapting to changes in lighting conditions.

- Resolution: Supports 4K (8MP) or higher, matching high-resolution sensors.

Application Scenarios:

- Smart Cities: Traffic monitoring (license plate recognition), public safety (face capture).

- Industrial Security: Fire prevention and theft prevention monitoring in factory workshops and warehouses.

Selection Criteria:

- Prioritize lenses with IP66 protection rating and support for wide dynamic range (WDR), such as the M12 lens supporting a 105° ultra-wide angle (suitable for monitoring in confined spaces).

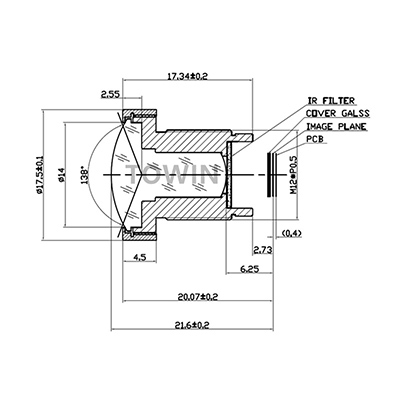

M12 CCTV lens 3-Megapixel IR corrected

4. Fisheye Lens: Ultra-Wide Angle Imaging and Scene Adaptation

Technical Characteristics:

- Fisheye lenses achieve 180°~270° ultra-wide angle imaging through non-linear projection, employing special lens designs (such as parabolic front lenses) and correction algorithms (such as software distortion correction). Its core advantage is that a single lens covers a large area of the scene, but edge distortion requires post-processing.

Key Parameters:

- Focal Length: ≤2mm (e.g., a 1.4mm fisheye lens).

- Field of View (FOV): 180°~220° (diagonal).

- Imaging Circle: Compatible with 1/2.7-inch to 1-inch sensors.

Application Scenarios:

- Panoramic Monitoring: Indoor panoramic monitoring, drone aerial photography.

- VR/AR: 360° content creation, requiring post-production stitching and correction.

Selection Criteria:

- Choose lenses that support software distortion correction (e.g., providing correction parameters), such as the Sigma 15mm f/1.4 fisheye lens (balancing image quality and field of view).

Fisheye lens 1/3″ Φ3 210° HD M12 lenses

5. Pinhole Lens: Miniature Covert Imaging Technology and Applications

Technical Characteristics:

- Pinhole lenses achieve covert imaging through an extremely small aperture (diameter ≤ 1mm), relying on the principle of rectilinear propagation of light. Its advantages are simple structure and small size (can be embedded inside devices), but its disadvantages are low light intake (requiring long exposures) and limited resolution.

Core Parameters:

- Aperture Size: 0.2mm~1mm; smaller apertures offer greater concealment but lower brightness.

- Focal Length: Fixed focal length (e.g., 3mm, 5mm), extremely large depth of field (almost infinite).

- Material: Metal casing (anti-electromagnetic interference) or plastic (low cost).

Application Scenarios:

- Covered Surveillance: Scenarios requiring concealed cameras, such as ATM machines and elevator interiors.

- Industrial Endoscopy: Internal equipment inspection (e.g., pipes, engines).

Selection Criteria:

- Prioritize lenses optimized for low light (e.g., F/2.8 aperture), such as customized M12 interface pinhole lenses (balancing concealment and image quality).

Pinhole-lens-10mm-IR-corrected

M12 Lenses Compatibility and Interface Standards

In modern optical applications, lens compatibility and interface standards are key factors in ensuring equipment effectiveness and flexibility. The M12 Lenses series is designed with this in mind, and its compatibility and interface standards enable its widespread application in various devices and systems.

1. Standardized Interface

- The M12 Lenses series uses the internationally recognized M12 interface, a standard widely used in industrial cameras, security monitoring, and automotive imaging. Key advantages of the M12 interface include:

- Compact Design: The compact design of the M12 interface makes it ideal for space-constrained devices such as small cameras and mobile devices.

- Reliable Connectivity: The M12 interface offers excellent interference resistance, ensuring stable signal transmission in various environments and improving image accuracy and clarity.

2. Compatibility Features

- Multiple Device Adaptations: This series of lenses is compatible with a wide range of camera modules, including industrial cameras, CCTV surveillance cameras, smartphone cameras, and drones.

- Multiple Resolution Support: The M12 Lenses series supports multiple resolutions from 720P to 4K, allowing users to choose the appropriate lens for different application scenarios to meet high-definition imaging needs.

- Different Focal Length Options: Offering multiple focal length options allows users to choose the most suitable lens based on specific observation needs, such as close-up or long-distance shooting.

3. Electrical Compatibility

- Support for Multiple Power Supply Methods: The lens design supports different power supply voltage ranges, adapting to different power environments and ensuring normal lens operation.

- Data Interface Standards: The M12 Lenses series connects to host devices through standardized data interfaces (such as USB, HDMI, etc.), ensuring stable and efficient data transmission.

4. Application Adaptability

- Security Monitoring: In the security field, its compatibility allows for easy lens replacement and upgrades across different brands and models of monitoring systems, simplifying maintenance and replacement processes.

- Automotive Industry: In automotive applications, the M12 Lenses seamlessly integrates with vehicle electronic systems, enabling real-time image processing and analysis.

- Industrial Automation: This series of lenses is widely used in machine vision systems to help improve production efficiency and product quality.

M12 Lenses Target Audience Segmentation

Due to differences in technical characteristics and scene adaptability, different models of the M12 Lenses series cater to different core target audiences. The following table clarifies the target audience, core needs matching points, and typical application scenarios for each lens, assisting in accurate selection.

| Lens Model | Target User Groups | Primary Applications | Key Selection Criteria |

| Low-Distortion Lenses | Industrial measurement engineers, medical imaging technicians, autonomous driving R&D personnel | 3D stereo vision, microscope imaging, lane line detection | Distortion rate ≤0.5%, resolution matching sensor pixels, TTL ≤15mm |

| Automotive Lenses | Automakers, ADAS system integrators, autonomous driving algorithm engineers | Front/surround-view cameras, blind-spot monitoring, multi-sensor fusion | AEC-Q100 certification, -40°C to +85°C operating temperature, F/2.0–F/2.8 aperture |

| Security Lenses | Security system installers, urban surveillance center operators, industrial safety managers | Traffic monitoring, facial recognition, warehouse fire/theft prevention | IP66 protection, 4K resolution, 2.8–12mm zoom / 3.6mm fixed focal length |

| Fisheye Lenses | Panoramic surveillance designers, VR/AR developers, drone operators | Indoor panoramic monitoring, 360° content creation, drone aerial photography | 180°–220° field of view, software-based distortion correction, compatible with ≥1/2.7″ sensors |

| Pinhole Lenses | Covert surveillance installers, industrial endoscopic inspectors, equipment maintainers | ATM monitoring, pipeline inspection, engine endoscopy | Aperture ≤1mm, F/2.8 aperture, metal housing for EMI shielding |

M12 Lenses Maintenance and Care Guide

| Maintenance Task | Instructions | Notes |

| Clean the Lens | Use a specialized lens cleaning cloth or lens cleaner to gently wipe the lens surface. | Avoid using paper towels or rough materials to prevent scratching the lens. |

| Check Connection Interface | Regularly inspect the M12 interface for secure connections, ensuring there is no looseness or oxidation. | Perform checks with the device powered off to avoid electrical accidents. |

| Prevent Moisture Ingress | Avoid exposing the lens to moisture in humid environments. | Use desiccant bags or other moisture-proof storage for the lens. |

| Temperature Control | Avoid placing the lens in extremely high or low-temperature environments. | Be cautious of direct sunlight on the lens in hot weather. |

| Regular Calibration | Periodically calibrate the lens based on usage to ensure image quality. | Refer to the manufacturer’s recommendations for calibration procedures. |

| Storage Conditions | When not in use, store the lens in a cool, dry place away from direct sunlight. | Use a lens cap to protect the lens surface from dust and scratches. |

| Inspect Optical Components | Regularly check the optical components for scratches or dirt that may affect image quality. | If issues are found, contact a professional for repairs. |

| Update Drivers and Firmware | Regularly check and update the camera module and lens drivers and firmware. | Ensure you are using the latest versions for optimal performance and compatibility. |

| Record Usage | Keep track of the lens’s usage frequency and environment for future maintenance reference. | Documentation can help analyze wear and establish maintenance schedules. |

| Professional Maintenance | For complex issues, seek professional technical support for inspection and repair. | Users should avoid disassembling the lens themselves, as it may lead to further damage. |

FAQs

How do I determine if an M12 lens is compatible with my device?

First, confirm that your device uses the M12×0.5 standard interface. Second, check the sensor size and pixel specifications to select the corresponding lens model. Finally, consider the specific application requirements and ensure the lens’s focal length, aperture, and other core parameters match.

What should I consider when choosing an M12 lens for automotive applications?

Prioritize automotive-grade certified lenses, ensuring their operating temperature range, vibration resistance, and electromagnetic interference resistance meet automotive standards. Simultaneously, consider the specific automotive functional requirements, matching the focal length and field of view to ensure the imaging range covers the required area. Pay attention to the lens’s autofocus response speed to meet real-time imaging needs in automotive applications.

What is the typical lifespan of the TOWIN M12 Lenses?

Under proper maintenance and normal use, the TOWIN M12 Lenses have a lifespan of 3-5 years; the Automotive Lens, due to its automotive-grade reinforced design, can have a lifespan extended to 5-8 years. However, use in harsh environments or improper maintenance may shorten the lifespan; regular maintenance and inspection are recommended.

What if the M12 Lenses produce poor image quality in low-light conditions?

Choose a lens model with a large aperture (small F-number) to increase light intake; check the lens surface for dirt and clean it promptly; in extremely low-light conditions, use an infrared fill light to improve image quality; prioritize lenses with infrared-compatible coating technology to ensure high-quality nighttime imaging.

Conclusion

The TOWIN M12 Lenses series holds a significant position in the optical imaging field due to its core advantages of miniaturization, high precision, and multi-scene adaptability. With the continuous development of intelligent and digital technologies, the market demand for miniature optical lenses will continue to grow, placing higher demands on lens performance, adaptability, and intelligence. In the future, TOWIN will continue to focus on the technological research and development of the M12 Lenses series, further improve the lens’s resolution, low-light performance, and environmental adaptability, expand into more niche application scenarios, launch more innovative products, and provide better optical imaging solutions for the development of various industries.