M12 and S-mount lenses for Industrial Cameras

1/1.2″ Lens | Star light lens F1.0 | IMX585

03/13/2025What does E.F.L. 1.85mm mean in a lens?

06/11/2025In the realm of industrial imaging and machine vision, precision, durability, and versatility are paramount. Among the myriad components that contribute to the efficacy of these systems, lenses play a pivotal role. Specifically, M12 and S-mount lenses have emerged as popular choices for industrial cameras, offering a blend of compactness, adaptability, and high performance. This article delves into the characteristics, applications, and advantages of M12 and S-mount lenses in industrial settings, organized under key subheadings for clarity.

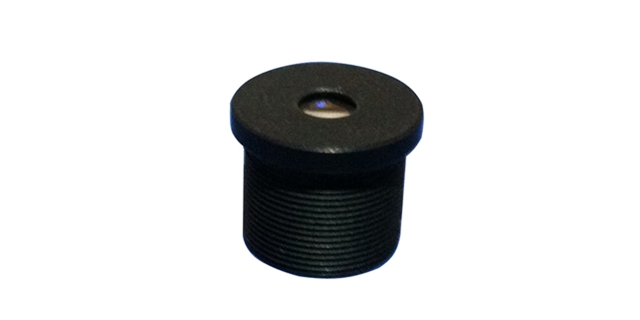

M12 Lenses: The Compact Powerhouses

M12 lenses, often referred to as S-mount lenses due to their standard M12X0.5 thread, are celebrated for their miniature size and direct threadability into the M12 mount of PCB cameras. This feature not only simplifies the assembly process but also reduces the overall footprint of the imaging system, making them ideal for applications where space is at a premium. M12 lenses come in a variety of types, including Low Distortion, Fisheye, Wide Angle, Low Light Sensitive, Pinhole, and Automotive lenses, catering to a wide range of industrial needs.

One of the key advantages of M12 lenses is their versatility. Whether it’s for surveillance in tight spaces, inspection of small components, or even in automotive applications where compactness is crucial, M12 lenses deliver sharp, clear images with minimal distortion. Their ability to adapt to various lighting conditions, thanks to options like Low Light Sensitive lenses, further enhances their utility in industrial environments.

S-Mount Lenses: Standardization and Ease of Use

On the other hand, S-mount, as a broader category that encompasses M12 lenses, also highlights the standardization and ease of use that these lenses bring to industrial cameras. The term “S-mount” is often used interchangeably with M12, emphasizing the standardized thread size that facilitates quick and easy lens changes. This standardization not only streamlines the manufacturing process but also ensures compatibility across different camera models and manufacturers.

For industrial applications, the compactness of M12 and S-mount lenses is a game-changer. In tight spaces or on moving parts, these lenses can capture high-quality images without adding unnecessary bulk. Moreover, their robust construction ensures reliability in harsh industrial environments, where dust, vibrations, and temperature fluctuations are common.Recommended reading: Fisheye lens M12 lens Automotive lens.

Applications Across Industries

M12 and S-mount lenses find applications across a multitude of industries. In manufacturing, they are used for quality control, ensuring that every component meets stringent standards. In the automotive sector, they play a crucial role in driver assistance systems and autonomous vehicles, providing clear vision in various lighting conditions. In surveillance, their compactness and versatility make them ideal for monitoring tight spaces and crowded areas.

Conclusion: Driving Industrial Imaging Excellence

In conclusion, M12 and S-mount lenses are indispensable components in the world of industrial cameras. Their compact size, adaptability, and high performance make them the go-to-choice for a wide range of industrial imaging applications. Whether it’s for surveillance, quality control, or automation, these lenses offer a reliable and efficient solution for capturing sharp, clear images in challenging environments. As industrial imaging technology continues to evolve, M12 and S-mount lenses will undoubtedly remain at the forefront, driving innovation and excellence in the field. With their proven track record of performance and reliability, they are set to shape the future of industrial imaging for years to come.