Low-Distortion Lens Meaning

What are car lens and their uses?

08/22/2025

High-Contrast Wide Angle Lens

08/22/2025In the world of optics, clarity is king. Whether you’re capturing a breathtaking landscape, conducting microscopic research, or inspecting intricate machinery, the quality of your lens determines the fidelity of your visuals. Enter the Low-Distortion Lens—a game-changer in optical technology designed to eliminate warping, bending, or blurring of images. But what does a Low-Distortion Lens Meaning?

Low-Distortion Lens Meaning: The Science Behind Flawless Vision

A Low-Distortion Lens achieves minimal optical aberrations—imperfections that curve straight lines or blur details—through advanced engineering. Unlike traditional lenses, which may suffer from barrel distortion (where edges bulge outward) or pincushion distortion (where edges pinch inward), a Low-Distortion Lens maintains geometric accuracy. This precision is achieved through advanced design techniques, such as:

- Aspherical surfaces: These non-spherical shapes correct distortion more effectively than conventional curved lenses.

- Multi-element construction: Combining multiple lens elements with varying refractive indices reduces chromatic aberration and spherical distortion.

- Computer-aided optimization: Modern software simulates light paths to fine-tune lens geometry for near-perfect performance.

By addressing these distortions, a Low-Distortion Lens ensures that images remain true to life, whether viewed through a camera, microscope, or binoculars.

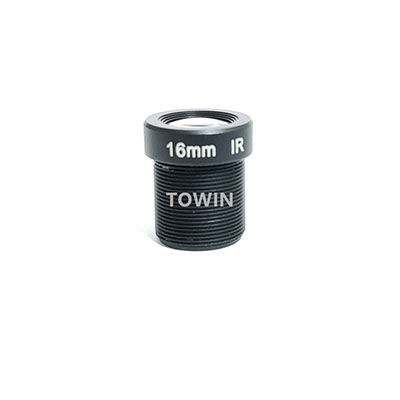

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

How Low-Distortion Lenses Enhance Optical Clarity

The benefits of Low-Distortion Lenses extend far beyond aesthetics. Here’s how they redefine clarity across industries:

1. Photography and Videography: Capturing Reality

For photographers, distortion can ruin a shot. A Low-Distortion Lens preserves straight lines in architectural photos, ensures accurate facial proportions in portraits, and maintains perspective in landscapes. For example, landscape photographers rely on these lenses to keep horizons level and trees vertical, avoiding the “leaning tower” effect common with standard lenses.

2. Microscopy: Unveiling the Unseen

In scientific research, distortion can mislead observations. A Low-Distortion Lens in microscopes provides a flat field of view, ensuring specimens are displayed uniformly without edge distortion. This is critical for analyzing cell structures, tissue samples, or material defects, where even slight warping could lead to incorrect conclusions.

3. Industrial Inspection: Precision Matters

Manufacturing and quality control demand pinpoint accuracy. Low-Distortion Lenses in machine vision systems enable robots to inspect products for flaws, measure components with sub-millimeter precision, and guide automated processes. For instance, in semiconductor manufacturing, these lenses ensure circuit patterns are etched flawlessly onto silicon wafers.

4. Augmented Reality (AR) and Virtual Reality (VR): Immersive Experiences

AR/VR headsets rely on Low-Distortion Lenses to prevent “screen-door effect” (visible gaps between pixels) and reduce eye strain. By minimizing distortion, users enjoy a seamless, immersive experience without nausea or disorientation—a must for gaming, training simulations, and virtual meetings.

5. Surveillance and Security: Crystal-Clear Monitoring

Security cameras equipped with Low-Distortion Lenses capture license plates, facial features, and license numbers with unmatched clarity, even at long distances. This is invaluable for law enforcement, traffic management, and retail loss prevention.

Low distortion 6mm Wide angle lens

The Technical Edge: Why Low-Distortion Lenses Outperform

The superiority of Low-Distortion Lenses lies in their ability to balance competing optical demands. Traditional lenses often compromise between distortion correction and other factors like light transmission or cost. Low-Distortion Lenses, however, use advanced materials (e.g., fluorite, ED glass) and coatings to maximize performance without sacrificing durability or affordability.

Choosing the Right Low-Distortion Lens

Not all Low-Distortion Lenses are created equal. When selecting one, consider:

- Application: A lens for microscopy differs from one for industrial inspection.

- Wavelength range: Some lenses are optimized for visible light, while others handle UV or infrared.

- Focal length: Shorter focal lengths offer wider fields of view but may introduce more distortion if not corrected.

- Mounting compatibility: Ensure the lens fits your camera, microscope, or sensor.

Low distortion industrial 8mm fixed focus lens

Conclusion

In an era where precision is non-negotiable, the Low-Distortion Lens stands as a testament to human ingenuity. By eliminating distortion, these lenses empower industries to achieve levels of clarity once thought impossible. From capturing perfect memories to advancing scientific discovery, their impact is undeniable.