How to Choose the Right Lens Mount: M12 vs C Mount vs CS Mount Comparison

2.8mm M12 wide angle lens for IMX290 5MP

01/09/20262.1mm M12 Wide Angle lens

01/13/2026Table of Contents

- Introduction

- M12 Lens Mount – High Adaptability for Miniaturized Scenarios

- C Mount – Precision & Stability for Industrial-Grade Scenarios

- CS Mount – Balancing Performance & Cost for Lightweight Scenarios

- Core Selection Parameter Comparison: M12, C Mount, and CS Mount

- Practical Selection Guides for Different Scenarios

- FAQs

- Conclusion

Introduction

The lens mount serves as the critical interface between a lens and imaging equipment, and its selection directly determines device compatibility, image quality, and application feasibility. In mainstream sectors like consumer electronics, industrial automation, and security surveillance, M12, C mount, and CS mount dominate the market. However, many users struggle with “parameter confusion” and “scene mismatches” when navigating M12 vs C mount vs CS mount for their specific needs.

M12 Lens Mount – High Adaptability for Miniaturized Scenarios

The M12 mount (also known as S-Mount), named for its 12mm thread diameter, is the top choice for consumer and small smart devices. The key to selection lies in balancing “space constraints” and “basic imaging needs”—a factor that often positions it as a compact alternative in M12 vs C mount vs CS mount comparisons.

M12 vs C Mount vs CS Mount

2.1 Core Traits of M12 Mount

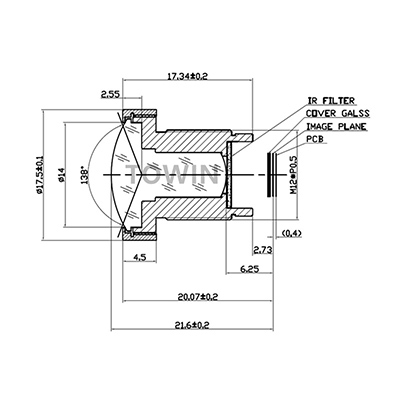

- Mechanical Structure for Selection: Featuring an M12×0.5 fine thread and ultra-short length (3-5mm), it is only compatible with devices with “installation space ≤20mm” and “load capacity ≤50g.” If your device is a micro-module (e.g., wearables, smartphone cameras), M12 is the clear front-runner in M12 vs C mount vs CS mount.

- Optical Traits as Selection Guides: Designed for short focal lengths, small sensor sizes (≤1/2.3″), and low distortion, it excels in “close-range imaging” and “wide-angle coverage.” With moderate light transmission (F2.0-F4.0), opt for large-aperture models for low-light scenarios.

- Selection Limitations: Not suitable for large sensors (>1/2.3″) or heavy-load equipment. Rule out M12 for industrial high-precision applications where C or CS mounts are more capable.

2.2 Sensor & Device Specification Compatibility

- Sensor Adaptation: For 1/4″ sensors → choose 2.1-3.6mm focal length (ultra-wide angle); for 1/2.3″ sensors → choose 5.9-8mm focal length (balancing field of view and clarity) to avoid vignetting or image distortion.

- Device Compatibility Boundaries: Only fits devices that are “compact, vibration-free, and require ‘clear identification’ rather than ‘precision measurement'”—such as smart home cameras, drones, and automotive surround-view modules.

2.3 Low-Distortion M12 Lens (S05911806056F) – Consumer-Grade High-Quality Scenarios

- Key Adaptability Points: 5.9mm focal length + 1/2.3″ sensor compatibility (ideal for 1/2.3″ pixel cameras); ≤0.9% low distortion + F5.6 aperture solves common consumer device pain points like “wide-angle stretching” and “low-light blurriness.”

- Target Scenarios: Drone aerial photography, action cameras, medium-sized smart home surveillance (installation space ≥15mm).

- Decision-Making Trigger: Choose this lens if you need to balance “wide-angle coverage” and “image fidelity” with a device load capacity ≤28g.

1/1.8″ Low distortion 5-Megapixel lens

2.4 Ultra-Wide Angle M12 Lens (S02112312022F) – Micro-Device Specialized

- Key Adaptability Points: 2.1mm ultra-short focal length + 1/2.3″ sensor (132°(D) super wide field of view); 15g lightweight design fits “micro-devices with installation space ≤12mm.”

- Target Scenarios: Miniature surveillance modules, smart wearables (e.g., smart glasses), smartphone front cameras, automotive surround-view lenses.

- Decision-Making Trigger: Prioritize this lens for extremely compact devices requiring ultra-wide coverage and pixel needs ≤12MP.

Low distortion lens 12-Megapixel M12 F2.2 CCTV lens

C Mount – Precision & Stability for Industrial-Grade Scenarios

The C mount is the “standard interface” for industrial automation. Selection hinges on “precision requirements,” “device compatibility,” and “harsh environment adaptability”—factors that make it a standout in M12 vs C mount vs CS mount for industrial use cases.

3.1 Core Selection Parameters: Flange Distance & Optical Compatibility

- Significance of Flange Distance: The fixed 17.526mm flange distance guarantees industrial-grade precision. If your equipment requires “cross-brand lens interchangeability” or “long-term stable operation,” the C mount’s standardized design prevents compatibility failures—a key advantage in M12 vs C mount vs CS mount comparisons for industrial settings.

- Value of Optical Compatibility: Supports large sensors (1/1.8″-1.1″) and high pixels (5MP-20MP) with complex lens structures (8-12 elements). For precision inspection (e.g., semiconductor defect detection), prioritize resolution (≥200lp/mm) during selection.

- Load & Size Boundaries: Load capacity ≤500g and length 30-80mm, fitting equipment without strict size limits—such as industrial cameras, inspection devices, and microscopes.

3.2 Industrial C Mount Selection Tips: 3 Core Principles to Avoid Mismatches

- Precision Matching: For inspection accuracy ≤0.01mm → choose high-resolution lenses (e.g., Towin C0802316M5 with ≤0.75% low distortion);

- Distance Adaptation: Close-range inspection (10cm-1m) → fixed focal lenses (8-16mm); mid-to-long range (1-5m) → varifocal lenses (8-40mm);

- Environment Adaptation: Low-light industrial settings → select large apertures (F1.4-F2.8) (e.g., Towin C084011814A5 with F1.4 aperture).

3.3 Varifocal C Mount Lens (C084011814A5) – Multi-Scenario Industrial Inspection

- Key Adaptability Points: 8-40mm varifocal (5x zoom range) + 1/1.8″ sensor compatibility (works with industrial sensors like imx185/imx385); F1.4 large aperture + IR correction meets low-light/day-night inspection needs.

- Target Scenarios: PCB defect inspection, electronic component measurement, industrial-grade traffic monitoring, assembly line visual positioning.

- Decision-Making Trigger: Choose this lens for industrial scenarios requiring “one lens for multiple uses” (covering close-to-long distances) with pixel needs ≤5MP.

8-40mm C mount IR corrected machine vision lenses

3.4 Fixed Focal C Mount Lens (C0802316M5) – Close-Range High-Precision Inspection

- Key Adaptability Points: 8mm fixed focal + 2/3″ sensor (≤0.75% ultra-low distortion); F1.6 aperture + manual focus, ideal for “close-range high-precision identification” (e.g., biometrics, barcode scanning).

- Target Scenarios: Smartphone screen scratch inspection, semiconductor packaging inspection, industrial microscope modules, robot gripping positioning.

- Decision-Making Trigger: Prioritize this lens for fixed inspection distances (10cm-∞) and extreme low-distortion requirements.

low distortion wide angle C-mount industrial lens

CS Mount – Balancing Performance & Cost for Lightweight Scenarios

The CS mount is a lightweight derivative of the C mount. Selection focuses on “compromising between size constraints and industrial-grade performance”—a sweet spot that makes it a popular choice in M12 vs C mount vs CS mount for surveillance and automotive applications.

4.1 Differences Between CS and C Mounts (Avoid Mismatches)

Core Differences:

- Flange Distance: CS mount (12.5mm) is 5.026mm shorter than C mount (17.526mm) → CS lenses cannot be directly installed on C mount cameras (requires a 5mm adapter ring); C lenses can be adapted to CS cameras (ensure weight ≤300g).

- Size & Weight: CS mount is 30% smaller and 50% lighter than C mount → Prioritize CS for space-constrained devices (≤50mm).

- Cost: CS mount is 20-30% more affordable than C mount → Choose CS for mass deployment (e.g., community surveillance) for better cost-effectiveness.

4.2 CS Mount Selection Advantages: Adaptability for Surveillance & Lightweight Industrial Scenarios

- Scenario-Oriented Selection: Security surveillance (bullet/dome cameras), automotive monitoring, intelligent transportation systems (ITS), small industrial inspection equipment;

- Core Need Matching: Supports 5MP-12MP pixels, large apertures (F1.2-F2.3) for night imaging, and lightweight design (≤300g)—perfect for “mass deployment + 24/7 operation.”

4.3 Varifocal CS Mount Lens (CS075161214M3) – Mass Surveillance Selection

- Key Adaptability Points: 7.5-16mm varifocal + 1/2″ sensor (52°-25° field of view coverage); F1.4 large aperture + IR correction solves the surveillance pain point of “poor night visibility”; manual aperture/focus fits mass-deployment cost requirements.

- Target Scenarios: Residential/mall security, automotive monitoring (buses/trucks), small intersection capture.

- Decision-Making Trigger: Prioritize this lens for mass deployment, day-night monitoring, and CS mount cameras.

1/2″ 7.5-16mm Manual Iris F1.4 3MP CS mount IR corrected CCTV lens

4.4 ITS-Specific CS Mount Lens (CCL1181250PAMP) – Intelligent Transportation Scenarios

- Key Adaptability Points: 12-50mm varifocal + 1/1.8″ sensor (33°-8° field of view for clear license plate capture within 50m); F1.5 aperture + P-Iris + IR correction adapts to harsh outdoor environments (24/7 operation).

- Target Scenarios: Highway monitoring, intersection license plate recognition, traffic flow statistics, outdoor bullet cameras.

- Decision-Making Trigger: Choose this lens for intelligent transportation scenarios requiring “long-distance capture + all-weather stability” with pixel needs ≤6MP.

12-50mm-P-Iris-Telephoto CCTV-lens

Core Selection Parameter Comparison: M12, C Mount, and CS Mount

5.1 Key Selection Parameter Comparison Table

| Selection Criteria | M12 Mount | C Mount | CS Mount | Selection Decision Guide |

| Flange Distance | 3-5mm (no fixed standard) | 17.526mm (industrial standard) | 12.5mm (fixed standard) | Cross-brand interchange → C; Space-constrained → CS |

| Compatible Sensor Size | 1/4″-1/2.3″ | 1/1.8″-1.1″ (large sensor) | 1/2″-1/1.8″ | High pixel/large sensor → C; Micro devices → M12 |

| Pixel Support | 2-12MP | 5-20MP (high pixel) | 3-6MP | Precision inspection → C; Consumer → M12; Surveillance → CS |

| Load Capacity | ≤50g | ≤500g | ≤300g | Heavy lenses → C; Lightweight → M12/CS |

| Core Advantages | Ultra-compact, low cost | High precision, compatibility, vibration resistance | Lightweight, cost-effective, excellent night imaging | Consumer → M12; Industrial precision → C; Surveillance → CS |

| Typical Selection Scenarios | Consumer electronics, micro-modules | Industrial inspection, machine vision, measurement | Security surveillance, ITS, automotive vision | Match directly by scenario |

| Bulk Purchase Cost | ≤$75/unit | $150-$750/unit | $75-$225/unit | Budget-limited → M12; Mass surveillance → CS |

5.2 Core Selection Conclusion: Lock the Mount in 30 Seconds

The M12 vs C mount vs CS mount decision boils down to your specific needs:

- If your device is “small, affordable, and sufficient for basic use” → Choose M12;

- If your needs are “precision, stability, and compatibility” → Choose C mount;

- If your scenario is “lightweight, cost-effective, and all-weather” → Choose CS mount.

Practical Selection Guides for Different Scenarios

6.1 Consumer Electronics: 3-Step M12 Mount Selection

- Define Space: Device installation length ≤15mm → Choose ultra-short focal length (2.1-3.6mm), e.g., Towin S02112312022F; Length 15-20mm → Choose medium focal length (5.9-8mm), e.g., Towin S05911806056F;

- Match Sensor: Select focal length by sensor size (1/4″ → 2.1mm; 1/2.3″ → 5.9mm) to avoid vignetting;

- Supplement Features: Low-light scenarios → Choose F2.2 or larger aperture; Wide-angle needs → Choose ≤3.6mm focal length + low distortion (≤1.5%).

6.2 Industrial Automation: C/CS Mount Decision Tree

When weighing M12 vs C mount vs CS mount for industrial applications, follow this framework:

- Step 1: Need large sensor (>1″)/high pixel (>12MP)/high load (>300g)? → Yes → Choose C mount;

- Step 2: Space-constrained device (≤50mm)/budget-limited/mass deployment? → Yes → Choose CS mount;

- Step 3: Match Lens Parameters: Close-range inspection → Fixed focal (8mm), e.g., Towin C0802316M5; Multi-distance inspection → Varifocal (8-40mm), e.g., Towin C084011814A5; Low-light → F1.4-F2.8 aperture.

6.3 Security/ITS Scenarios: Core CS Mount Selection Tips

- Prioritize Environment: Night surveillance → Choose F1.4 or larger aperture (e.g., Towin CS075161214M3 with F1.4); Outdoor scenarios → Select IR-corrected lenses;

- Match Distance: Indoor (≤10m) → 7.5-16mm; Road (10-50m) → 12-50mm, e.g., Towin CCL1181250PAMP;

- Cost Control: Mass deployment → Choose manual aperture/focus (e.g., CS075161214M3) to reduce procurement costs.

M12 vs C Mount vs CS Mount

FAQs

Q1: Can I install a CS lens on a C mount camera?

A: Yes, but you need a 5mm adapter ring to compensate for the flange distance. Ensure the lens weight ≤300g (CS mount’s load limit) to prevent interface damage or blurry images—an important detail in M12 vs C mount vs CS mount compatibility.

Q2: Should I choose M12 or CS mount for surveillance?

A: Single miniature surveillance (e.g., pinhole cameras) → M12; Mass deployment (e.g., communities/roads) → CS mount (better night imaging and compatibility, e.g., Towin CS075161214M3).

Q3: Is there a significant precision difference between C and CS mounts for industrial inspection?

A: Yes! Precision measurement (accuracy ≤0.01mm) → C mount (e.g., Towin C0802316M5 with ≤0.75% distortion); General visual inspection → CS mount (more cost-effective).

Q4: Can M12 mounts be used in industrial scenarios?

A: Only for “miniature industrial modules” (e.g., small barcode scanners) that are “vibration-free and have low precision requirements.” Otherwise, prioritize C/CS mounts in M12 vs C mount vs CS mount industrial selections.

Conclusion

The core logic of lens mount selection—especially in M12 vs C mount vs CS mount—is “scenarios define needs, needs match parameters, parameters lock the mount”: M12 handles “small and efficient” consumer scenarios, C mount supports “precise and stable” industrial demands, and CS mount adapts to “lightweight and cost-effective” surveillance/automotive applications.

Towin’s 6 lenses (M12: S05911806056F, S02112312022F; C Mount: C084011814A5, C0802316M5; CS Mount: CS075161214M3, CCL1181250PAMP) perfectly align with the core scenarios of the three mounts. You can directly follow the path “Scenario → Mount → Product” for selection.

If you still have selection doubts, check detailed parameters via the product links or refine your choices based on your device’s sensor size, installation space, and precision requirements. Remember: There’s no “best mount” in M12 vs C mount vs CS mount—only the “most suitable selection” for your unique needs.