Zero-distortion lens for high-precision metrology

IR corrected lenses for 24/7 day/night surveillance

01/31/2026Table of Contents

- Introduction

- What Are Zero Distortion Lenses?

- Core Optical Design Principles & Architecture

- Key Performance Parameters for Metrology

- Typical Applications of Zero Distortion Lenses in Industrial Metrology

- Performance Comparison

- Recommended Towin Zero Distortion Lenses for Metrology

- How to Choose the Right Zero Distortion Lens for Metrology?

- FAQs

- Conclusion

Key Takeaways

- Zero-distortion lenses (ultra-low distortion, <0.05%) enable accurate size/shape restoration in high-precision metrology by minimizing image distortion.

- Core optical designs (e.g., aspherical lenses, IRCF integration, multi-group lens structures) are critical for distortion control.

- Key parameters: Distortion rate (<0.01%~<0.05%), resolution (8MP~20MP), focal length (3.5mm~100mm), mount type (M12/M7/C-Mount), and M.O.D. (0.1m~0.8m).

- Ideal for industrial measurement, OCR, surface inspection, security metrology, and machine vision.

- Towin’s zero-distortion lineup covers diverse metrology needs with high compatibility and reliability.

Introduction

In high-precision metrology, even microscopic image distortion can lead to critical measurement errors, affecting product quality control, industrial automation, and scientific research. Zero-distortion lens—defined by ultra-low distortion rates (<0.05%)—have become indispensable tools for applications requiring pixel-accurate image reproduction. Towin, a trusted provider of industrial optical components, offers a range of zero-distortion lenses tailored to metrology scenarios, combining advanced optical design, high resolution, and broad compatibility. This guide dives into the fundamentals, performance, applications, and selection of zero distortion lenses for high-precision metrology.

What Are Zero Distortion Lenses & Why Are They Suitable for Metrology?

1. Definition of Zero Distortion Lenses

Zero distortion lenses (also called ultra-low distortion lenses) are optical components designed to minimize geometric distortion to near-negligible levels (<0.05%), ensuring that the shape, size, and relative positions of objects in the image match their real-world counterparts. Unlike standard lenses, which may introduce barrel, pincushion, or mustache distortion, zero distortion lenses use specialized optical architectures to correct these anomalies.

2. Metrology Compatibility

Metrology relies on quantitative accuracy—measurements of length, angle, and shape must be consistent with physical reality. Here’s why zero distortion lenses are a perfect fit:

- Eliminate distortion-induced errors: Even 0.1% distortion can cause 1mm error in a 1m object, which is unacceptable for high-precision tasks.

- Maintain edge-to-edge sharpness: Critical for measuring small features or large fields of view (FOV) uniformly.

- Support high-resolution sensors: Pair with 8MP~20MP sensors to capture fine details for precise analysis.

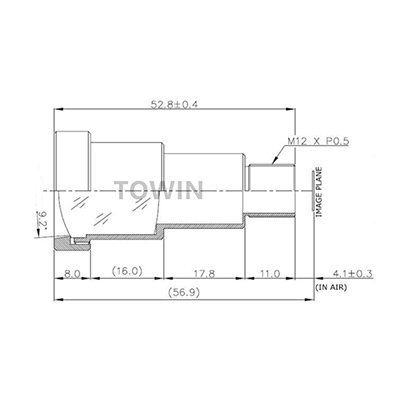

50mm M12 Zero Distortion Lens

Core Optical Design Principles & Architecture

Zero distortion lenses achieve ultra-low distortion through sophisticated design and component selection. Key principles include:

1. Optical Correction Mechanisms

- Aspherical lens elements: Reduce spherical aberration and distortion by adjusting the curvature of lens surfaces, eliminating the need for extra lens groups (e.g., Towin’s 3G2P+IRCF structure in S03513206628F).

- Multi-group lens configuration: Combine glass (G) and plastic (P) lenses in optimized sequences (e.g., 3G2P) to balance distortion correction, light transmission, and compactness.

- IR filter integration (IRCF): For lenses used in low-light or night metrology (e.g., security surveillance metrology), built-in IRCF blocks infrared light to avoid image blurring (S03513206628F features IRCF).

2. Structural Features

| Design Element | Function | Towin Product Examples |

| Fixed iris | Ensures stable light input for consistent measurement | S03513206628F, CCL1250MP |

| Manual iris | Adapt to variable light conditions (e.g., industrial environments) | C3511028M20, C10001035M8 |

| Compact mount (M12/M7) | Ideal for space-constrained metrology devices | S03513206628F, M71801200245 |

| C-Mount | Compatible with large-format sensors (1.1″/2/3″) for high-resolution metrology | C3511028M20, C7501028M8 |

Key Performance Parameters for Metrology

The following parameters directly determine the suitability of a zero-distortion lens for high-precision metrology. Data is sourced from Towin’s product lineup:

| Parameter | Definition | Towin Product Range | Importance for Metrology |

| Distortion Rate | Deviation from true object shape | <0.01% (S03513206628F) ~ <0.05% (M71801200245) | Directly impacts measurement accuracy; lower = better for high-precision tasks |

| Resolution | Ability to capture fine details | 8MP (C10001035M8) ~ 20MP (C3511028M20) | Critical for measuring small features (e.g., micro-components) |

| Focal Length | Distance from lens to image sensor | 3.5mm (wide-angle) ~ 100mm (telephoto) | Determines FOV: short focal length = wide FOV (large objects), long focal length = narrow FOV (distant/small objects) |

| Aperture (F-Number) | Light transmittance | F2.5 (CCL1250MP) ~ F4.5 (M71801200245); adjustable (F2.8~32) | Fixed aperture = stable exposure; adjustable = flexible for variable light |

| Minimum Object Distance (M.O.D.) | Closest distance to focus on an object | 0.1m (S03513206628F) ~ 0.8m (C10001035M8) | Important for close-up metrology (e.g., surface inspection of small parts) |

| Sensor Compatibility | Supported image sensor size | 1/3.2″ ~ 1.1″ | Must match the metrology system’s sensor to avoid vignetting or reduced resolution |

Typical Applications of Zero Distortion Lenses in Industrial Metrology

Zero distortion lenses are widely used in scenarios requiring precise quantitative analysis. Below are key use cases with Towin product recommendations:

- Dimensional Measurement: Measure length, width, diameter, and distance of components (e.g., automotive parts, electronics).

Recommended: CCL1250MP (50mm focal length, <0.03% distortion) for mid-range precision; C3511028M20 (20MP, <0.02% distortion) for high-precision tasks.

- Optical Character Recognition (OCR): Read text/barcodes on components for traceability without shape distortion.

Recommended: C3511028M20 (specifically designed for OCR, 1.1″ sensor compatibility).

- Surface Inspection: Detect defects (scratches, dents) on product surfaces by maintaining true-to-life image geometry.

Recommended: C7501028M8 (75mm focal length, manual focus/iris for precise targeting) or C10001035M8 (100mm focal length for detailed close-ups).

- Security Surveillance Metrology: Monitor and measure objects in security scenarios (e.g., access control, perimeter monitoring).

Recommended: S03513206628F (wide-angle 78° FOV, built-in IRCF for night use).

- Machine Vision Metrology: Integrate with automated systems for real-time quality control (e.g., assembly line inspection).

Recommended: M71801200245 (compact M7 mount, <0.05% distortion) for space-constrained automation devices.

Performance Comparison: Zero Distortion Lenses vs. Traditional Metrology Lenses

Zero distortion lenses outperform traditional metrology lenses in key metrics critical for precision. Here’s a detailed comparison:

| Feature | Zero Distortion Lenses (Towin) | Traditional Metrology Lenses |

| Distortion Rate | <0.01% ~ <0.05% (near zero) | 0.1% ~ 0.5% (significant deformation) |

| Resolution | 8MP ~ 20MP (high-definition) | 2MP ~ 10MP (lower detail) |

| Edge-to-Edge Uniformity | High (consistent sharpness) | Low (blurry edges) |

| Sensor Compatibility | Broad (1/3.2″ ~ 1.1″) | Limited (mostly 1/2″ ~ 2/3″) |

| Operation Flexibility | Fixed/manual iris/focus; compact mounts | Mostly fixed settings; bulkier mounts |

| Ideal Use Case | High-precision metrology (±0.01mm error) | General measurement (±0.1mm error) |

Recommended Towin Zero Distortion Lenses for Metrology

Towin offers a diverse range of ultra-low distortion lenses to meet different metrology needs. Click the product links for detailed specifications:

| Product Model | Core Selling Points | Key Specifications | Ideal Application |

| S03513206628F | Ultra-low distortion (<0.01%), built-in IRCF, wide-angle | 13MP, 3.5mm focal length, M12 mount, M.O.D. 0.1m | Security metrology, wide FOV object measurement |

| M71801200245 | Compact M7 mount, Φ8 sensor compatibility | 18mm focal length, F4.5 aperture, M.O.D. 50mm | Space-constrained automation metrology |

| CCL1250MP | High light transmittance (F2.5), long focal length | 50mm focal length, M12 mount, <0.03% distortion | Mid-range precision dimensional measurement |

| C3511028M20 | 20MP high resolution, OCR-optimized | 35mm focal length, C-Mount, adjustable iris (F2.8~22) | High-precision OCR, detailed component measurement |

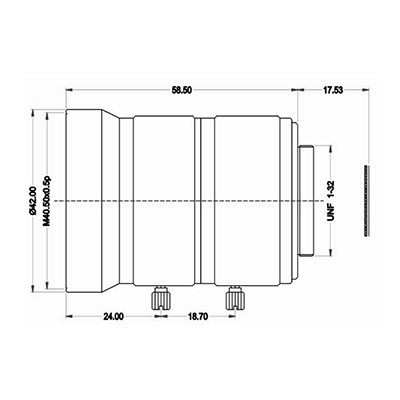

| C10001035M8 | Long focal length, manual focus/iris | 100mm focal length, 8MP, M.O.D. 0.8m | Close-up surface inspection, small part metrology |

| C7501028M8 | Balanced performance, 2/3″ sensor compatibility | 75mm focal length, adjustable iris (F2.8~16), <0.02% distortion | Versatile industrial metrology (dimensional + surface inspection) |

How to Choose the Right Zero-Distortion Lens for Metrology?

Follow this step-by-step guide to select a lens that matches your metrology system and accuracy requirements:

1. Define Precision Requirements

- For ultra-high precision (error <±0.01mm): Choose distortion rate <0.02% (e.g., C3511028M20, C7501028M8).

- For high precision (error <±0.05mm): Select distortion rate <0.03% (e.g., CCL1250MP).

- For general precision (error <±0.1mm): Opt for distortion rate <0.05% (e.g., M71801200245).

2. Match Sensor Size

- Check your metrology system’s sensor size (e.g., 1/3.2″, 1/2″, 2/3″, 1.1″).

- Ensure the lens’s “IMAGE FORMAT” matches or exceeds the sensor size to avoid vignetting.

3. Select Focal Length Based on FOV

- Calculate required FOV using the formula: FOV = 2 × arctan (object size / (2 × working distance)).

- Example: To measure a 1m-wide object at 2m working distance → choose wide-angle lens (3.5mm, S03513206628F, 78° FOV).

- To measure a 5cm-wide object at 1m working distance → choose long focal length (75mm, C7501028M8, 6.5° HFOV).

4. Confirm Mount Compatibility

- M12 mount: Suitable for compact systems (e.g., IoT metrology devices) → S03513206628F, CCL1250MP.

- M7 mount: Ultra-compact automation → M71801200245.

- C-Mount: Large-format sensors/high-resolution systems → C3511028M20, C10001035M8.

5. Evaluate Environmental Needs

- Low-light/night metrology: Choose lens with built-in IRCF (S03513206628F).

- Variable light conditions: Select adjustable iris (C3511028M20, C10001035M8).

6. Verify Resolution

- For micro-component measurement: ≥13MP (S03513206628F, C3511028M20).

- For general measurement: 8MP (C7501028M8, C10001035M8).

100mm C-Mount Zero Distortion Lens

FAQs

Q1: Is a lower distortion rate always better for metrology?

A: Yes. In high-precision metrology (e.g., aerospace, electronics), even 0.01% distortion can affect results. Prioritize lenses with <0.02% distortion for critical tasks.

Q2: Can zero distortion lenses be used with any metrology sensor?

A: No. The lens’s “IMAGE FORMAT” must match the sensor size. Using a lens with a smaller sensor compatibility will cause vignetting (dark edges).

Q3: Fixed vs. adjustable iris—what’s better for metrology?

A: Fixed iris ensures stable exposure, ideal for controlled environments (e.g., lab measurement). Adjustable iris is better for industrial settings with variable light.

Q4: Does Towin offer custom zero distortion lenses for specific metrology needs?

A: Yes. Towin provides custom solutions for focal length, mount type, and environmental adaptability (e.g., waterproof, high-temperature resistance). Contact our team for details.

Q5: How to calibrate a zero distortion lens for metrology?

A: Use a calibration chart (e.g., checkerboard pattern) to verify distortion and adjust the lens focus/iris. Towin provides calibration guidelines for all products.

Conclusion

Zero-distortion lens are the backbone of high-precision metrology, enabling accurate, reliable measurements across industries. Towin’s ultra-low distortion lineup—with distortion rates as low as <0.01%, high resolution (up to 20MP), and broad compatibility—meets the diverse needs of industrial measurement, OCR, surface inspection, and more.

By following our selection guide, you can find the perfect lens for your metrology system. For personalized recommendations or custom solutions, visit Towin’s official website or contact our technical support team today.