What are M8 and M12 lenses?

Anti-reflective optical lens supplier

08/11/2025

Low Distortion Large Aperture Lens

08/11/2025In the rapidly evolving world of imaging technology, compactness and precision are no longer optional—they’re essential. Whether you’re designing a cutting-edge surveillance system, a medical device, or a consumer electronics gadget, the right lens can make or break your project. Enter M8 and M12 lenses, two game-changing solutions that combine miniaturization with exceptional optical performance. But what exactly are M8 and M12 lenses, and why are they causing such a stir in industries worldwide?

What are M8 and M12 Lenses?

M8 and M12 lenses are miniature, threaded lens assemblies designed for applications where space is limited but optical clarity is critical. The “M” denotes their metric thread size: M8 lenses have an 8mm outer diameter, while M12 lenses measure 12mm. These lenses are commonly used in machine vision, automotive cameras, IoT devices, and medical imaging, where their compact form factor and high-resolution capabilities shine.

M8 Lenses: The Tiny Titans of Imaging

M8 lenses are the smallest in the family, often weighing just a few grams. Their diminutive size makes them ideal for embedded systems, drones, and endoscopes, where every millimeter counts. Despite their size, M8 lenses deliver sharp images with minimal distortion, thanks to advanced coatings and precision-engineered glass elements.

M8 mount low distortion lens

Key Features of M8 Lenses:

Ultra-compact design: Perfect for space-constrained applications.

- High resolution: Capable of capturing fine details in microscopic or distant objects.

- Low distortion: Critical for applications like 3D scanning or metrology.

- Cost-effective: Often more affordable than larger lenses with similar specs.

For example, a M8 lens might be used in a smartphone’s macro camera to capture intricate textures or in a miniature surveillance drone for covert operations.

M12 Lenses: The Versatile Workhorses

M12 lenses strike a balance between size and performance, making them the most widely used variant in industrial and consumer applications. Their 12mm diameter allows for more complex optical designs, including zoom capabilities and wider apertures, without sacrificing portability.

Key Features of M12 Lenses:

- Balanced size and performance: Suitable for a broad range of applications.

- Wide field of view: Ideal for dashcams, security cameras, and robotics.

- High light sensitivity: Excellent for low-light environments like automotive interiors.

- Durability: Often rated for harsh conditions, including vibrations and temperature extremes.

A M12 lens might power a factory floor inspection camera or a smart home security system, where reliability and image quality are paramount.

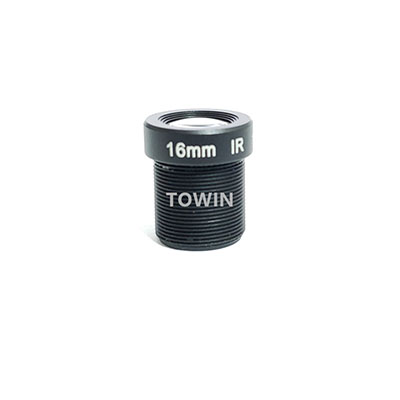

8mm-M12-CCTV-lens

Why M8 and M12 Lenses Stand Out

1. Compactness Without Compromise

- Traditional lenses often require bulky housing and complex mounting systems. M8 and M12 lenses eliminate this hassle, offering plug-and-play integration with modern sensors and circuit boards.

2. Cost Efficiency

- Smaller lenses mean lower material costs and simpler manufacturing processes. This translates to significant savings for OEMs without sacrificing performance.

3. Adaptability

- Both M8 and M12 lenses come in fixed-focal, varifocal, and motorized zoom configurations, making them adaptable to virtually any imaging task.

4. Industry-Standard Threading

- The M-thread design ensures compatibility with off-the-shelf mounts and filters, reducing development time and costs.

Applications of M8 and M12 Lenses

The versatility of these lenses has led to their adoption across diverse fields:

- Automotive: Backup cameras, driver-monitoring systems, and ADAS sensors.

- Medical: Endoscopes, dental cameras, and diagnostic imaging tools.

- Industrial Automation: Quality control, barcode scanning, and robotic vision.

- Consumer Electronics: Action cameras, VR headsets, and wearable devices.

For instance, Teledyne DALSA, a leader in machine vision, offers a range of M12 lenses optimized for high-speed factory automation. Their lenses combine low distortion and high MTF (Modulation Transfer Function) to ensure crisp images even at rapid production speeds.

Low distortion M12 S-mount board lens

Choosing the Right Lens: M8 vs. M12

Selecting between M8 and M12 lenses depends on your specific needs:

- Opt for M8 if you need the smallest possible footprint and can tolerate a narrower field of view.

- Choose M12 if you require wider angles, better low-light performance, or zoom capabilities.

The Future of Miniature Lenses

As industries like autonomous vehicles and augmented reality demand ever-smaller, more powerful imaging systems, M8 and M12 lenses are poised to play an even bigger role. Innovations in liquid lenses and metamaterials promise to enhance their performance further, opening doors to applications we’ve yet to imagine.

Conclusion

M8 and M12 lenses represent a revolution in compact imaging, offering unmatched precision in a fraction of the space of traditional optics. Whether you’re a hobbyist tinkering with a drone or an engineer designing the next generation of medical devices, these lenses provide a powerful, cost-effective solution to your imaging challenges.