Distortion Correction Software vs Optical Lens Design

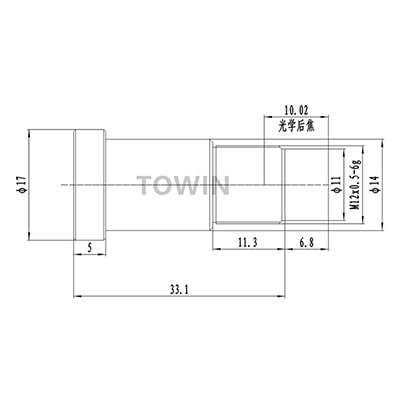

1/3″ 2.3mm 4-Megapixel Wide angle lens

01/27/2026Table of Contents

- Introduction

- Optical Lens Design: Core Technologies and Characteristics of Distortion Control

- Distortion Correction Software: Core Technologies and Characteristics

- Distortion Correction Software vs Optical Lens Design Tables

- Functional Positioning: Post-Correction vs Pre-Prevention

- Application Synergy & Complementarity

- Mainstream Solutions for Industrial Imaging

- FAQs

- Conclusion

Key Takeaways

- Optical lens design controls distortion through pre-design (aberration balance), achieving lossless imaging but with high cost and long cycles.

- Distortion correction software uses post-algorithm (calibration-modeling-correction) for flexible adjustment, low cost but with potential image quality loss.

- The mainstream industrial solution is “optical design for basic distortion control + software correction for fine optimization” to balance performance and cost.

- Optical design is irreplaceable for high-precision measurement; software correction is preferred for low-cost, large-field-of-view scenarios.

Introduction

In imaging systems, distortion correction software and optical lens design undertake core functions of “post-correction” and “pre-prevention” respectively. They differ significantly in technical paths, application scenarios, and performance impacts, but jointly aim to improve imaging quality. This article compares the two from four dimensions: technical principles, functional positioning, application scenarios, and development trends.

I. Optical Lens Design: Core Technologies and Characteristics of Distortion Control

Distortion is a geometric aberration of optical lenses, caused by inconsistent magnification across different fields of view (FOV). Positive distortion occurs when the magnification at the edges is higher than at the center, resulting in an outwardly bulging image; negative distortion happens when edge magnification is lower than the center, leading to an inwardly concave image. The core of optical lens design lies in suppressing distortion through aberration balancing rather than eliminating it entirely—this is because lenses must simultaneously optimize other aberrations such as spherical aberration, coma, field curvature, and chromatic aberration to avoid trade-offs.

1. Core Distortion Control Technologies

- Lens Structure Optimization: Combining multiple lens groups (e.g., the “object-space telecentric / image-space telecentric” structure of telecentric lenses) ensures that light from different FOVs enters the lens as parallel light, maintaining consistent magnification. This is a core method for high-precision industrial lenses.

- Aspheric Lens Application: Aspheric lenses can correct multiple geometric aberrations with a single lens, replacing combinations of multiple spherical lenses. This not only reduces distortion but also simplifies the lens structure and minimizes volume.

- Aperture Position Adjustment: The aperture position affects aberration distribution. Reasonable aperture adjustment balances distortion between the center and edges while optimizing light transmittance.

- Specialty Glass Selection: Optical glass with different refractive indices can adapt to different lens curvatures, reducing light refraction distortion and assisting in distortion optimization.

2. Core Advantages

- Non-Destructive Imaging: The only method to control distortion without losing pixel details, suitable for high-precision dimension measurement and other scenarios requiring extreme pixel resolution and detail retention.

- Long-Term Stability: Once the lens is finalized, its distortion characteristics are fixed, unaffected by external environments (e.g., temperature, computing power), with no post-deployment debugging costs.

- Full-Scenario Adaptability: No reliance on calibration or algorithms—distortion-free imaging is achieved in real time. Ideal for high-speed acquisition, embedded devices without computing capabilities, and other scenarios where software correction is unfeasible.

3. Core Disadvantages

- High Cost and Long Lead Time: R&D, manufacturing, and testing costs for high-precision, low-distortion lenses (e.g., industrial telecentric lenses, line scan lenses) are much higher than ordinary lenses. Additionally, long design cycles make it difficult to respond quickly to market demands.

- Design Constraints: It is challenging to simultaneously achieve three key indicators: large FOV, large aperture, and low distortion. For example, wide-angle lenses inevitably have a certain degree of distortion to maintain FOV.

- No Post-Deployment Adjustability: Lens assembly errors, wear, or aging over long-term use can increase distortion. The finalized optical design cannot correct such post-deployment distortion.

TOWIN lens

II. Distortion Correction Software: Core Technologies and Characteristics

Distortion correction software is a typical application of digital image processing in imaging. Its core is a three-step process: calibration – modeling – correction. Essentially, it “remaps” distorted image pixels through algorithms to restore geometric authenticity. Currently, it is mainly used in medium-to-low precision imaging scenarios or as a “secondary optimization tool” in high-precision applications.

1. Core Distortion Correction Technologies

- Traditional Calibration Algorithms: Represented by the Zhang Zhengyou calibration method, this approach captures high-precision calibration boards (e.g., checkerboards) to obtain lens intrinsic parameters (focal length, principal point) and distortion parameters (radial distortion, tangential distortion). It fits a polynomial distortion model and completes correction through pixel geometric transformation, serving as the mainstream method in industrial imaging with sub-pixel-level accuracy.

- Calibration-Free Correction Algorithms: Designed for scenarios without calibration boards, these algorithms fit distortion using image feature points (e.g., lines, corners). Suitable for non-professional scenarios such as consumer photography and security monitoring, with lower accuracy than calibration-based methods.

- Deep Learning Correction Algorithms: Trained on large datasets of distorted/undistorted image pairs using neural networks, these algorithms correct complex nonlinear distortion. Ideal for extreme distortion scenarios such as fisheye lenses and panoramic lenses, delivering more natural results but with high computing power consumption and poor real-time performance.

2. Core Advantages

- Ultra-Low Cost: No hardware material costs—only calibration boards (hundreds to thousands of yuan) and algorithm software/open-source code (e.g., OpenCV’s built-in distortion correction module) are required. A single algorithm set can be reused across multiple lenses.

- Flexible Adjustability: Re-calibration and correction can be performed at any time based on lens distortion characteristics and scenario requirements, adapting to rapid product iterations and enabling “digital upgrades” for aging lenses.

- Breaking Optical Constraints: Can correct extreme large-FOV distortion (e.g., over 50% distortion in fisheye lenses) that is difficult to resolve through optical design, achieving “visually distortion-free” effects beyond optical capabilities.

3. Core Disadvantages

- Image Quality Loss: Pixel interpolation during correction causes partial detail loss. Edge pixel stretching may lead to blurring, with significant quality degradation under extreme distortion.

- Reliance on Accurate Calibration: Calibration board precision, shooting angle, distance, and lighting conditions all affect calibration results. Calibration errors directly lead to correction failure, requiring a certain level of operational expertise.

- Computing Power and Real-Time Limitations: Complex correction algorithms (e.g., deep learning) require high computing power and cannot run on low-end embedded devices (e.g., microcontrollers, small cameras). Lightweight algorithm optimization for high-speed imaging scenarios sacrifices partial correction accuracy.

- Distortion-Only Correction: Cannot address other optical aberrations (e.g., chromatic aberration, spherical aberration, optical blur). For images with both distortion and optical distortion, software only corrects geometric shape without improving overall image quality.

Ⅲ. Distortion Correction Software vs Optical Lens Design Tables

| Comparison Dimensions | Optical Lens Design | Distortion Correction Software |

| Core Technical Path | Pre-design (aberration balance), suppressing distortion via lens structure, material, and aperture optimization | Post-algorithm (calibration-modeling-correction), repairing distortion via pixel remapping |

| Impact on Image Quality | Lossless imaging with no pixel detail loss | Pixel interpolation loss, prone to blurring in extreme scenarios |

| Cost and Cycle | High R&D and manufacturing costs, long design cycle | Ultra-low cost, fast deployment, reusable algorithms |

| Stability and Adjustability | Long-term stability, non-adjustable after finalization, no environmental interference | Dependent on computing power and calibration, flexible adjustment, susceptible to environmental impacts |

| Applicable Distortion Range | Suitable for medium-low distortion control, hard to break through large-FOV optical constraints | Capable of correcting extreme distortion, breaking through optical design limitations |

| Additional Capabilities | Simultaneously optimizing multiple optical aberrations such as spherical aberration and chromatic aberration | Only correcting geometric distortion, unable to resolve other optical aberrations |

| Core Applicable Scenarios | High-precision measurement, high-speed imaging, devices without computing capabilities | Medium-low precision scenarios, large-FOV scenarios, low-cost mass production scenarios |

Ⅳ. Functional Positioning: Post-Correction vs Pre-Prevention

1. Distortion Correction Software

Core Functions

- Distortion detection and parameter calculation (distortion coefficient, focal length)

- Real-time/offline correction, adaptive to dynamic environments

- Multi-sensor data fusion (e.g., camera-lidar point cloud calibration)

Typical Scenarios

- Autonomous driving: Ensure accurate recognition of road signs and pedestrians

- Industrial inspection: Auxiliary correction for medium-low precision measurement

- Consumer electronics: Smartphone cameras (algorithm-based imaging optimization)

2. Optical Lens Design

Core Functions

- Lens combination optimization to reduce aberrations and distortion

- Control FOV, depth of field and light transmittance for specific needs

- Hardware integration design (collaboration with sensors and diaphragms)

Typical Scenarios

- Professional photography: Cinema lenses (stable images via fixed aperture)

- Medical equipment: Endoscope lenses (high resolution and low distortion for precision surgery)

- Aerospace exploration: Telescope lenses (long focal length, lightweight design for long-distance observation)

V. Application Synergy & Complementarity

Complementarity

- Software correction: Suitable for scenarios with unknown distortion parameters or dynamic adjustment needs (e.g., autonomous driving, consumer electronics)

- Optical design: Irreplaceable for scenarios requiring ultimate imaging quality (e.g., professional photography, medical imaging)

Synergy

- Hybrid correction: Optical design reduces basic distortion, while software corrects residual errors for higher precision

- Standardization promotion: ISO standards enhance interoperability between lens design and correction software, boosting technology popularization

Ⅵ. Mainstream Solutions for Industrial Imaging

In practical imaging system design, no single method can achieve optimal distortion performance on its own. The synergistic solution of “optical lens design for fundamental distortion control + software correction for fine optimization” has become the industry standard for industrial machine vision and professional imaging applications. Its core lies in prioritizing the two approaches based on scenario-specific precision requirements, cost budgets, and real-time performance needs to achieve an optimal performance-cost balance.

1. High-Precision Measurement Scenarios

- Core: Prioritize optical lens design to suppress distortion to an ultra-low level of ≤0.1%, eliminating the majority of inherent distortion from the optical system.

- Supplementary: Use software correction as a secondary step to perform sub-pixel level fine correction via high-precision calibration. This corrects minor distortion caused by lens assembly errors and temperature fluctuations, achieving an even higher measurement accuracy of 0.01 pixel-level.

2. Large FOV Industrial Imaging Scenarios

- Core: Optical lens design prioritizes balancing FOV, light transmittance, and manufacturing costs, controlling distortion within a ≤5% correctable range to avoid over-engineering and excessive hardware costs.

- Supplementary: Treat software correction as the primary optimization measure, and correct residual distortion using calibrated algorithms to achieve distortion-free imaging in large FOVs, balancing both field of view and imaging quality effectively.

3. Low-Cost Industrial / Consumer Imaging Scenarios

- Core: Adopt low-cost standard optical lenses (with distortion potentially >10%) to minimize hardware material and manufacturing costs for mass deployment.

- Supplementary: Use software correction as the only distortion processing method, completing calibration and correction via mature open-source algorithms (e.g., OpenCV). This achieves visually distortion-free imaging at a minimal cost, meeting basic imaging and detection requirements.

4. High-Speed Real-Time Imaging Scenarios

- Core: Prioritize optical lens design to control distortion within an acceptable range, avoiding computing power consumption caused by complex software correction and ensuring the real-time performance of high-speed image acquisition and processing.

- Supplementary: For scenarios requiring higher precision, implement lightweight software correction algorithms (e.g., simplified polynomial models) to perform minor distortion correction with almost no loss of real-time performance.

Optical Lens Suppliers

FAQs

– Will software distortion correction reduce image resolution?

Yes. Pixel interpolation during correction leads to partial detail loss. The loss is negligible for medium-low precision scenarios but obvious in extreme distortion correction.

– Can optical lenses achieve zero distortion?

No. Optical design balances multiple aberrations, so it only suppresses distortion to a very low level (e.g., <0.1% for high-precision lenses) rather than eliminating it completely.

– Which is more cost-effective for small-batch industrial projects?

Software correction. It avoids high R&D costs of custom lenses and can be reused across multiple devices, reducing overall project costs.

– Can software correct chromatic aberration or spherical aberration?

No. Software only remaps pixel geometry to correct distortion, but cannot fix other optical aberrations (chromatic aberration, spherical aberration, optical blur) caused by lens hardware.

– How to choose between the two for autonomous driving cameras?

Adopt hybrid solution: Optical design ensures basic distortion control and stability; software correction adapts to dynamic environments (e.g., lens installation deviation) and corrects residual distortion for accurate perception.

Conclusion

Optical lens design and distortion correction software are not competing but complementary in imaging systems. Optical design lays the foundation for lossless, stable imaging, while software correction provides flexible, low-cost optimization. With the development of industrial imaging (e.g., higher precision, larger FOV, lower cost), the hybrid solution of “optical pre-control + software post-optimization” will become the mainstream trend.