Coating Technologies for Low-Distortion Lens

Automotive tail light lens

11/19/2025

Wide-angle CS-Mount lenses for surveillance

11/19/2025In the world of precision optics, achieving minimal distortion is critical for applications ranging from professional photography to scientific research. A Low-Distortion Lens ensures that light passes through with minimal refraction errors, preserving the integrity of the captured image. However, even the most advanced lens designs can benefit from specialized coatings to further reduce distortion, enhance durability, and optimize performance.

Why Coating Technologies Matter for Low-Distortion Lenses

A Low-Distortion Lens is engineered to minimize chromatic and spherical aberrations, but environmental factors like reflections, scratches, and moisture can degrade its performance. Coatings act as a protective layer, improving light transmission, reducing glare, and ensuring long-term reliability. Without proper coatings, even the best lenses may struggle to deliver consistent results under varying conditions.

Low distortion lens 12-Megapixel M12 F2.2 CCTV lens

Top Coating Technologies for Low-Distortion Lens

1. Anti-Reflective (AR) Coatings

Anti-reflective coatings are essential for Low-Distortion Lenses as they minimize surface reflections, allowing more light to pass through the lens. This technology uses multiple layers of dielectric materials to cancel out reflections at specific wavelengths, enhancing contrast and reducing ghosting.

Benefits:

- Improves light transmission by up to 99.9% -es internal reflections that cause flare and ghosting

- Enhances color accuracy in high-resolution imaging

AR coatings are widely used in camera lenses, microscopes, and telescopes, where clarity and precision are paramount.

2. Broadband Anti-Reflective (BBAR) Coatings

For applications requiring performance across a wide spectral range, BBAR coatings are ideal. These coatings are optimized to reduce reflections across multiple wavelengths, making them suitable for Low-Distortion Lenses used in multispectral imaging, fluorescence microscopy, and laser systems.

Benefits:

- Works effectively from ultraviolet (UV) to infrared (IR) wavelengths

- Minimizes chromatic aberration in broadband applications

- Enhances signal-to-noise ratio in scientific instruments

3. Diamond-Like Carbon (DLC) Coatings

DLC coatings provide exceptional hardness and scratch resistance, making them perfect for Low-Distortion Lenses exposed to harsh environments. This amorphous carbon coating mimics the properties of diamond, offering superior durability without compromising optical performance.

Benefits:

- Extremely resistant to scratches and abrasions

- Chemical inertness prevents degradation from oils and solvents

- Low friction coefficient reduces dust and debris accumulation

DLC coatings are commonly used in industrial lenses, automotive optics, and aerospace applications.

4. Hydrophobic and Oleophobic Coatings

Water and oil repellent coatings protect Low-Distortion Lenses from smudges, fingerprints, and environmental contaminants. These coatings create a smooth surface that causes water droplets to bead up and roll off, while oils and dirt are easily wiped away.

Benefits:

- Maintains optical clarity in humid or dirty environments

- Reduces cleaning frequency and maintenance costs

- Prevents water spots and streaking on lens surfaces

This technology is particularly valuable for outdoor photography, surveillance cameras, and underwater optics.

5. Metal Oxide Coatings for Thermal Stability

For Low-Distortion Lenses used in high-temperature applications, metal oxide coatings like titanium dioxide (TiO₂) or zirconium dioxide (ZrO₂) provide thermal stability and resistance to discoloration. These coatings maintain their optical properties even under extreme heat, making them ideal for industrial lasers and defense systems.

Benefits:

- Withstands temperatures up to 500°C without degradation

- Maintains consistent refractive index across varying temperatures

- Resistant to thermal shock and cycling

25mm Low Distortion Machine Vision Lens

Applications of Coating Technologies for Low-Distortion Lens

The advancements in coating technologies have expanded the use of Low-Distortion Lenses across multiple industries:

- Photography & Cinematography: High-end cameras rely on AR and hydrophobic coatings to capture stunning images with minimal distortion.

- Medical Imaging: Endoscopes and microscopes use BBAR coatings for accurate diagnosis and research.

- Aerospace & Defense: DLC and thermal-stable coatings ensure reliable performance in extreme conditions.

- Automotive: Advanced driver-assistance systems (ADAS) depend on scratch-resistant lenses for safety.

FAQs

What is the primary purpose of coatings on a low-distortion lens?

Coatings enhance light transmission, reduce reflections, and protect the lens from scratches, moisture, and thermal damage, ensuring optimal performance in various conditions.

How do anti-reflective coatings improve image quality?

By minimizing surface reflections, AR coatings allow more light to pass through the lens, reducing flare and ghosting while improving contrast and color accuracy.

Are DLC coatings suitable for all types of lenses?

DLC coatings are best suited for lenses exposed to harsh environments, such as industrial or outdoor applications, due to their exceptional hardness and chemical resistance.

Can hydrophobic coatings prevent fogging on lenses?

While hydrophobic coatings repel water, they do not prevent fogging caused by temperature changes. Anti-fog coatings are specifically designed for this purpose.

Do thermal-stable coatings affect the refractive index of a lens?

No, metal oxide coatings maintain a consistent refractive index even under extreme temperatures, ensuring stable optical performance.

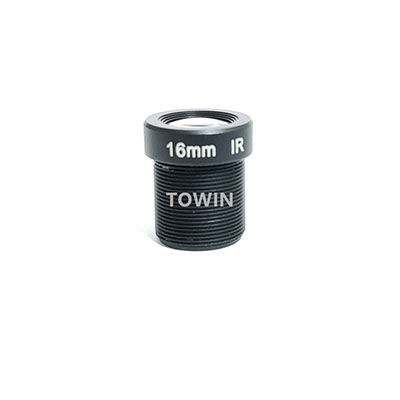

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

Conclusion

The development of advanced coating technologies for low-distortion lens has transformed the field of precision optics, enabling clearer, more reliable imaging in demanding applications. From anti-reflective and hydrophobic coatings to DLC and thermal-stable solutions, these innovations ensure that Low-Distortion Lenses deliver unmatched performance in photography, medicine, aerospace, and beyond.