Low-Distortion Lenses in Industrial Inspection

What Is a Automotive Lens?

11/21/2025

Telecentric CS-Mount lenses for measurement

11/21/2025In the fast-paced world of industrial inspection, precision and accuracy are paramount. Whether it’s quality control in manufacturing or inspecting complex mechanical components, having the right equipment is crucial for ensuring that every part meets the required specifications. Low-Distortion Lenses in Industrial Inspection boost clarity and detail for better imaging.

What are Low-Distortion Lenses?

Low-distortion lenses are optical devices designed to minimize or eliminate the visual distortions often associated with traditional lenses. Distortions such as barrel and pincushion effects can significantly affect the quality of images captured during industrial inspections, leading to inaccurate measurements and misinterpretations. By utilizing advanced optical technologies, Low-Distortion Lens in Industrial Inspection ensure that images remain true to scale and maintain their clarity, which is crucial for making precise decisions in quality control and defect detection.

The Importance of Low-Distortion Lens in Industrial Inspection

In industrial settings, precision is not just important—it is non-negotiable. Distortion can lead to inaccurate measurements, compromised quality assurance, and ultimately, product failure. The use of Low-Distortion Lens in Industrial Inspection helps to:

- Improve Measurement Accuracy: With minimal distortion, these lenses provide an undistorted view of the object being inspected, ensuring that measurements taken are precise and reliable.

- Enhance Image Quality: The clarity and sharpness of the image are greatly improved, which is essential for detecting defects, cracks, or inconsistencies that may otherwise go unnoticed.

- Streamline Inspection Processes: With more accurate images, inspectors can work faster and more efficiently, reducing the time needed for each inspection and increasing overall productivity.

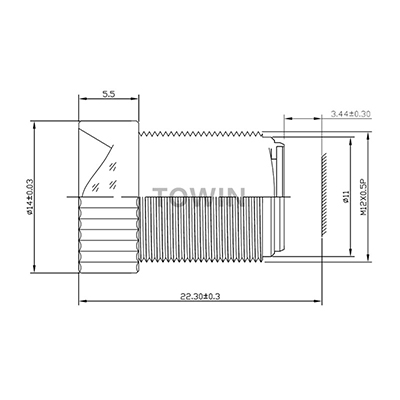

Low distortion wide angle 4.6mm 71° M12 mount lens

Applications of Low-Distortion Lenses in Industrial Inspection

The adoption of Low-Distortion Lenses in Industrial Inspection is transforming several industries. Below are some of the primary areas where these lenses are making a significant impact:

- 1. Manufacturing and Production Lines: Automated visual inspection systems equipped with Low-Distortion Lenses can quickly detect defects in products, such as scratches, cracks, or misalignments, ensuring that only high-quality items reach consumers.

- 2. Electronics Inspection: For inspecting small components like circuit boards, where precision is critical, Low-Distortion Lenses offer clear, detailed images that enable the identification of even the most minuscule flaws.

- 3. Aerospace: The aerospace industry relies heavily on Low-Distortion Lenses in Industrial Inspection for inspecting critical components such as turbine blades, engine parts, and airframes to ensure safety and performance.

- 4. Automotive: Automotive manufacturers use Low-Distortion Lenses to inspect car parts for structural integrity, weld quality, and surface defects to meet stringent safety standards.

Why Choose Low-Distortion Lenses for Industrial Inspection?

When choosing lenses for industrial applications, several factors need to be considered. Low-Distortion Lenses stand out due to the following advantages:

- High Accuracy and Detail: The low-distortion design ensures that even the smallest details of an object are captured without visual interference.

- Consistency Across the Entire Field of View: Unlike traditional lenses, which can experience varying levels of distortion across different areas of the image, Low-Distortion Lenses provide a consistent, clear view throughout.

- Increased Efficiency: The precision offered by Low-Distortion Lenses reduces the need for retakes or adjustments, resulting in faster inspection cycles and increased throughput.

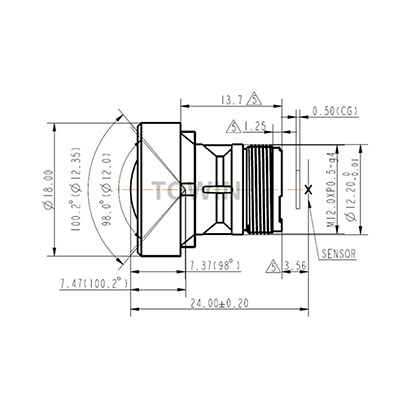

25mm Low Distortion Machine Vision Lens

How Low-Distortion Lenses Enhance Inspection Systems

- 1. Inspection systems, whether manual or automated, rely on high-quality images to make accurate assessments. Low-Distortion Lenses in Industrial Inspection play a pivotal role in these systems by providing:

- 2. Clearer and More Reliable Images: Low-Distortion Lenses remove blurring distortions, helping inspectors make decisions with more reliable data.

- 3. Better Integration with Image Processing Software: These lenses integrate with advanced algorithms, enabling quicker, more precise defect detection and classification.

- 4. Compatibility with High-Resolution Cameras: Paired with high-res cameras, Low-Distortion Lenses capture fine details, boosting inspection system performance.

FAQs

How do Low-Distortion Lenses improve inspection accuracy?

Low-distortion lenses reduce visual distortions such as barrel or pincushion effects, which could skew measurements or make defect detection difficult. This leads to higher accuracy in inspections.

Are Low-Distortion Lenses compatible with all types of industrial cameras?

Yes, Low-Distortion Lenses work with many industrial cameras, especially high-res, automated visual inspection ones.

What industries benefit most from Low-Distortion Lens in Industrial Inspection?

Automotive, aerospace, electronics, and manufacturing industries use Low-Distortion Lenses for precise, high-quality critical inspections.

Can Low-Distortion Lenses reduce inspection time?

Low-Distortion Lenses offer clear, accurate images, streamlining inspections and cutting time without compromising quality.

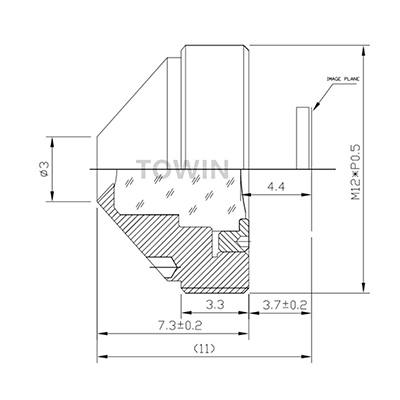

Low distortion wide angle 3.4mm 85° M12 mount lens

Conclusion

In conclusion, Low-Distortion Lenses in Industrial Inspection represent a significant leap forward in ensuring high-precision and efficient inspections across various industries. These lenses eliminate distortion, offering clearer images to help teams detect defects, boost measurement accuracy, and streamline inspections.