Bespoke optical lens designer & supplier

M12 Lenses for Medical Endoscopy

11/06/2025

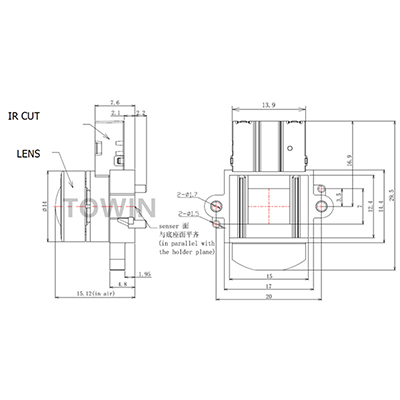

3.2mm M12 wide angle board HD lens

11/06/2025In an era where precision and customization define technological progress, businesses across industries—from aerospace to medical imaging—demand optical lenses tailored to their unique needs. Enter the world of Bespoke Optical Lens Designer & Supplier, a niche yet critical player in the optics industry. By combining cutting-edge engineering, material science, and client-centric innovation, these specialists deliver lenses that transcend off-the-shelf limitations.

Why Choose a Bespoke Optical Lenses Designer & Supplier?

The demand for customized optical lenses has surged as industries recognize that standard solutions often fall short. A Bespoke Optical Lens Designer & Supplier bridges this gap by offering lenses engineered to exact specifications, ensuring optimal performance in even the most demanding environments. Unlike mass-produced alternatives, bespoke lenses are designed with precision, durability, and functionality in mind, addressing challenges such as aberration correction, thermal stability, and lightweight construction.

Product Parameters: The Science Behind Customization

A Bespoke Optical Lenses Designer & Supplier prioritizes flexibility in design parameters, allowing clients to dictate critical features. Key parameters include:

- 1. Material Selection: From fused silica for high-temperature applications to low-dispersion glass for imaging systems, materials are chosen based on thermal expansion, refractive index, and chemical resistance.

- 2. Surface Accuracy: Sub-micron surface finishes (e.g., λ/10 or better) ensure minimal light scattering, critical for laser systems and high-resolution cameras.

- 3. Coating Options: Anti-reflective (AR), hydrophobic, or broadband coatings enhance performance in specific wavelengths (UV, IR, or visible light).

- 4. Geometric Tolerances: Tight control over radius, thickness, and wedge angles prevents misalignment in optical assemblies.

- 5. Aspherical Designs: Non-spherical surfaces correct spherical aberration, reducing system complexity and weight.

For example, a medical endoscope manufacturer might require a lens with a 0.5mm thickness, AR coating for 400–700nm wavelengths, and a surface roughness below 5nm. A Bespoke Optical Lens Designer & Supplier can deliver this with precision.

M12 wide angle 2.1 board lens

Industry-Specific Applications

- Aerospace & Defense: Lenses for satellite imaging systems must withstand extreme temperatures and radiation. Bespoke solutions here often use radiation-hardened materials and aspherical designs to minimize distortion.

- Medical Devices: Endoscopes, ophthalmic instruments, and diagnostic tools rely on lenses with biocompatible coatings and ultra-high precision.

- Industrial Automation: Machine vision systems demand lenses with high contrast and minimal chromatic aberration for quality control.

- Consumer Electronics: AR/VR headsets benefit from lightweight, compact lenses with wide field-of-view designs.

Towin’s Edge as a Bespoke Optical Lens Designer & Supplier

Towin exemplifies the expertise of a Bespoke Optical Lens Designer & Supplier. Their offerings include:

- Custom Aspherical Lenses: Reducing system size by up to 50% compared to spherical alternatives.

- Molded Polymer Lenses: Cost-effective solutions for high-volume applications like automotive LiDAR.

- Hybrid Lenses: Combining glass and polymer elements for thermal stability and lightweight design.

- Rapid Prototyping: Iterative design cycles within 2–4 weeks, accelerating time-to-market.

Towin’s in-house metrology labs ensure every lens meets ISO 10110 standards, with traceability reports for critical industries.

FAQs

1. What is the typical lead time for a bespoke lens?

Lead times vary based on complexity but average 4–8 weeks. Simple designs may be expedited, while multi-element systems require longer.

2. How does cost compare to off-the-shelf lenses?

Bespoke lenses are pricier initially but offer long-term savings by reducing assembly complexity and improving system performance.

3. Can you replicate an existing lens design?

Yes! Reverse engineering services use 3D scanning and optical profiling to recreate legacy lenses with improved specifications.

4. What industries benefit most from custom lenses?

Aerospace, medical, defense, and industrial automation see the highest ROI due to stringent performance requirements.

5. Do you handle small-batch orders?

Absolutely. Many Bespoke Optical Lens Designer & Supplier firms cater to low-volume, high-mix production, ideal for startups and niche applications.

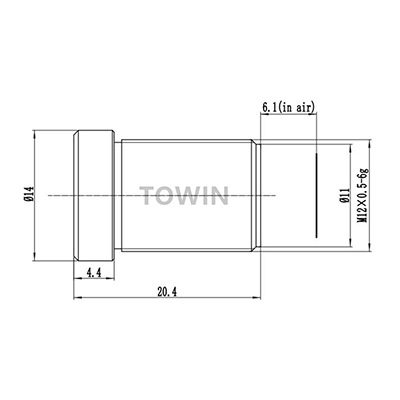

Low distortion CCTV 25mm F2.5 M12 lens

The Future of Bespoke Optics

Advancements in freeform optics and additive manufacturing are pushing the boundaries of what’s possible. A Bespoke Optical Lens Designer & Supplier now integrates AI-driven design tools to optimize shapes for specific wavelengths, reducing development time. Sustainability is also a focus, with eco-friendly coatings and recyclable materials gaining traction.

Conclusion

In a world where “close enough” rarely suffices, partnering with a Bespoke Optical Lens Designer & Supplier is not just a choice—it’s a necessity. From correcting aberrations in astronomical telescopes to enabling minimally invasive surgeries, custom lenses are the unsung heroes of modern technology.