Custom aperture lenses for industrial applications

Machine vision lenses used for in robotics

10/16/2025

M12 lens warranty and return policy

10/16/2025In the fast-paced world of industrial automation, quality and precision are non-negotiable. For industries relying on machine vision, quality control, or laser processing, standard lenses often fall short. Enter custom aperture lenses for industrial applications—a game-changing solution designed to meet the unique demands of modern manufacturing.

Towin, a leader in optical innovation, specializes in crafting lenses that deliver unmatched performance. Their custom aperture lenses for industrial applications are engineered to optimize light control, reduce distortions, and enhance imaging clarity. Whether you’re inspecting microchips, guiding robotic arms, or measuring components with sub-millimeter accuracy, these lenses are built to excel.

Why Custom Aperture Lenses Matter in Industrial Settings

Industrial environments demand reliability. Standard lenses may struggle with variable lighting, harsh temperatures, or vibrations, leading to inconsistent results. Custom aperture lenses for industrial applications address these challenges by offering:

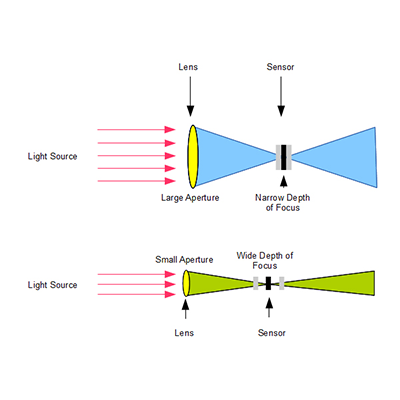

- Precision Aperture Control: Adjustable apertures regulate light intake, ensuring optimal exposure for high-speed imaging.

- Durability: Constructed with rugged materials like stainless steel or hardened coatings, these lenses withstand extreme conditions.

- Compatibility: Designed to integrate seamlessly with cameras, sensors, and laser systems used in automotive, electronics, or pharmaceuticals.

Towin’s lenses stand out for their ability to balance performance and cost. By tailoring aperture size, focal length, and coating types, they eliminate compromises between speed and accuracy.

Wide aperture lenses

Key Product Parameters of Towin’s Custom Aperture Lenses

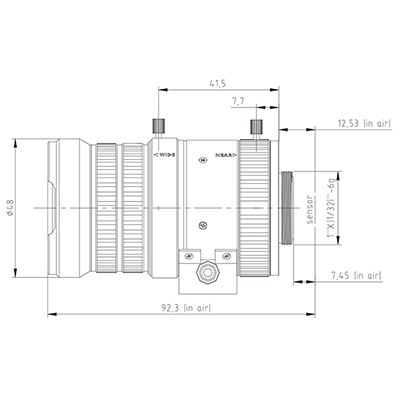

Towin’s custom aperture lenses for industrial applications are defined by their technical specifications:

- Aperture Range: From f/1.4 to f/22, allowing flexibility in light management.

- Focal Lengths: 8mm to 150mm, catering to close-up inspections and wide-field applications.

- Wavelength Compatibility: Support for visible light (400–700nm), UV (200–400nm), and infrared (700–1100nm).

- Coating Options: Anti-reflective, waterproof, or scratch-resistant coatings to enhance longevity.

- Mounting Standards: C-Mount, CS-Mount, or custom flanges for compatibility with industry-specific hardware.

For example, a semiconductor manufacturer might require a lens with a narrow aperture (f/16) to minimize depth of field errors during wafer inspection. Towin’s engineers can design such a lens with precision alignment features, ensuring sub-micron accuracy.

Towin’s Unique Advantages in Industrial Optics

What sets Towin apart is its commitment to customization without compromise. Their process involves:

- Consultation: Understanding your application’s challenges, such as ambient light interference or vibration sensitivity.

- Prototyping: Rapid development of sample lenses for testing in real-world conditions.

- Mass Production: Scalable manufacturing with strict quality control to meet bulk orders.

Additionally, Towin’s global network ensures timely support. A client in Germany reported a 40% reduction in inspection errors after switching to Towin’s lenses, citing improved contrast and reduced glare.

Macro lenses with adjustable aperture

FAQs

1. What industries benefit most from custom aperture lenses?

Automotive (defect detection), electronics (PCB inspection), and medical devices (laser surgery systems) rely heavily on these lenses for accuracy.

2. How do custom apertures improve imaging?

By controlling light intensity, custom apertures reduce overexposure in bright environments and enhance detail in low-light settings.

3. Are custom lenses more expensive than off-the-shelf options?

Initial costs may be higher, but long-term savings from reduced downtime and improved product quality often justify the investment.

4. Can Towin’s lenses withstand harsh factory conditions?

Yes. Their lenses are tested for temperature resistance (-40°C to 85°C), humidity tolerance, and shock resistance.

5. What is the lead time for custom orders?

Typically 4–6 weeks, depending on complexity. Towin offers expedited services for urgent projects.

6. Choosing the Right Partner for Your Optical Needs

Selecting a supplier for custom aperture lenses for industrial applications requires evaluating their technical expertise, production capacity, and customer support. Towin’s track record—including partnerships with Fortune 500 companies—speaks to their reliability.

Optimal Aperture for Sharpness

Final Thoughts

As industries embrace Industry 4.0, the demand for custom aperture lenses for industrial applications will surge. Towin’s ability to merge innovation with practicality positions them as a leader in this space. By investing in tailored optical solutions, businesses can achieve unprecedented efficiency and quality.