M12 lenses with M12x0.5 thread size

Waterproof optical lens supplier

08/25/2025

What is a car infrared thermal imaging lens?

08/25/2025In the world of imaging technology, precision and adaptability are non-negotiable. Whether you’re designing surveillance systems, industrial automation tools, or medical devices, the right lens can make or break performance. Enter M12 lenses with M12x0.5 thread size—a game-changing solution that combines compact design, high optical clarity, and effortless compatibility.

M12 Lenses with M12x0.5 Thread Size: The Perfect Blend of Form and Function

M12 lenses, also known as S-mount lenses, are renowned for their miniature size and exceptional optical quality. The “M12” refers to the 12mm outer diameter of the lens barrel, while the M12x0.5 thread size specifies the pitch and diameter of the threading used to secure the lens to cameras or other devices. This standardized threading ensures compatibility across a wide range of hardware, making M12 lenses a go-to choice for engineers and designers.

But why does thread size matter? The M12x0.5 specification strikes a balance between stability and flexibility. The 0.5mm pitch allows for precise adjustments during focusing, while the 12mm diameter ensures the lens remains compact enough for space-constrained applications. This combination is particularly valuable in industries like robotics, where every millimeter counts, or in automotive systems, where vibration resistance is critical.

12mm M12 mount low-distortion lens

Key Benefits of M12 Lenses with M12x0.5 Thread Size

1. Compact and Lightweight Design

M12 lenses are ideal for applications where size and weight are constraints. Their small footprint allows them to fit into tight spaces without sacrificing image quality. For example, in drone technology, M12 lenses enable high-resolution imaging without adding bulk to the aircraft’s payload.

2. High Optical Performance

Despite their size, M12 lenses deliver sharp, distortion-free images. Advanced coatings minimize chromatic aberration and glare, making them suitable for demanding environments like outdoor surveillance or machine vision.

3. Easy Integration and Customization

The M12x0.5 thread size simplifies installation and replacement. Users can quickly swap lenses or adjust focus without specialized tools, reducing downtime in production lines or field operations.

4. Cost-Effective Solution

M12 lenses are often more affordable than larger alternatives, offering a budget-friendly option without compromising on quality. This makes them accessible for startups and small-scale projects.

5. Durability and Reliability

Built to withstand harsh conditions, M12 lenses are resistant to dust, moisture, and shock. Their robust design ensures consistent performance in factories, warehouses, or even extreme weather.

1.5mm F2.0 M12 Mount Automotive lens

Applications of M12 Lenses with M12x0.5 Thread Size

The versatility of M12 lenses makes them indispensable across industries:

- Surveillance and Security: Compact cameras equipped with M12 lenses provide discreet monitoring in retail stores, banks, or public spaces.

- Industrial Automation: Machine vision systems rely on M12 lenses for quality control, barcode scanning, and robotic guidance.

- Automotive: Advanced driver-assistance systems (ADAS) use M12 lenses for lane detection, traffic sign recognition, and parking assistance.

- Medical Devices: Endoscopes and diagnostic tools benefit from the miniature size and high resolution of M12 lenses.

- Consumer Electronics: Action cameras, smart glasses, and wearables leverage M12 lenses for portable, high-quality imaging.

Common Misconceptions About M12 Lenses

Despite their advantages, some myths persist about M12 lenses:

“M12 lenses are only for low-resolution cameras.”

- Modern M12 lenses support resolutions up to 4K and beyond, dispelling the notion that small lenses compromise quality.

“The M12x0.5 thread size is outdated.”

- On the contrary, this standard remains widely adopted due to its reliability and ease of use.

“M12 lenses are too fragile for industrial use.”

- Many M12 lenses feature rugged housings and IP67 ratings, making them suitable for demanding environments.

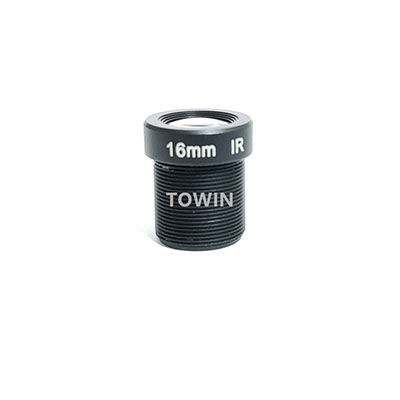

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

Future Trends in M12 Lens Technology

As imaging demands evolve, M12 lenses continue to innovate. Expect to see advancements in:

- Liquid Lenses: These adaptive lenses use electrowetting to adjust focus instantly, eliminating the need for mechanical parts.

- Multi-Sensor Integration: Combining M12 lenses with infrared or thermal sensors enhances functionality in security and automotive applications.

- AI-Optimized Optics: Smart lenses that automatically correct for distortions or lighting conditions could redefine imaging efficiency.

Conclusion

M12 lenses with M12x0.5 thread size represent a sweet spot in imaging technology—compact yet powerful, versatile yet reliable. Their standardized design ensures seamless integration, while their optical performance meets the highest standards. Whether you’re a hobbyist, engineer, or business owner, these lenses offer a cost-effective, high-quality solution for virtually any imaging challenge.