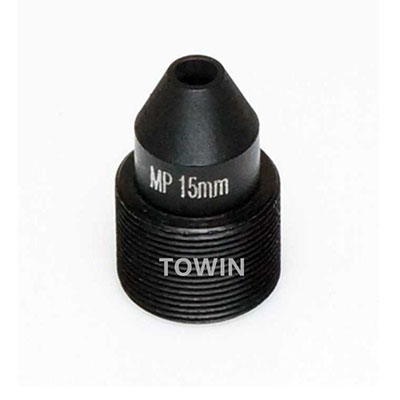

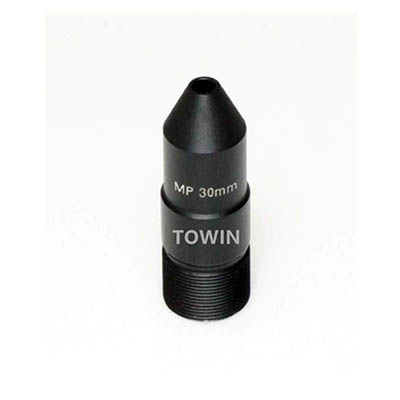

Thermally stable pinhole lens

How to Focus a Fisheye Lens

09/15/2025

Low distortion CCTV 8mm 27° M12 mount lens

09/15/2025In the realm of high-precision optics, thermal stability is not a luxury—it’s a necessity. Fluctuating temperatures can distort lens performance, compromising image clarity and measurement accuracy in critical applications like aerospace, medical imaging, and industrial automation. Towin, an optical solutions leader, tackles this challenge with its Thermally Stable Pinhole Lens, ensuring top performance in extreme heat.

Thermally Stable Pinhole Lens: Core Specifications

Towin’s Thermally Stable Pinhole Lens is designed to excel in environments where conventional lenses fail. Below are its key parameters:

2.1mm wide angle pinhole lens lens

1. Thermal Stability Range: -40°C to +120°C

The lens maintains its optical alignment and pinhole diameter within ±0.5% across this extreme range, ensuring consistent performance in outdoor, industrial, or aerospace settings.

2. Pinhole Diameter: 10–200 μm (customizable)

Available in precise increments, the pinhole size caters to applications requiring varying levels of light control, from laser beam shaping to high-resolution microscopy.

3. Material Composition: Fused silica with low-CTE coating

The use of ultra-low thermal expansion (CTE) materials minimizes dimensional changes, while a proprietary coating enhances durability and reduces light scatter.

4. Optical Distortion: <0.05%

Near-zero distortion ensures geometric accuracy, critical for 3D reconstruction and metrology tasks.

5. Wavelength Range: 350–2,500 nm

Compatible with UV, visible, and NIR spectra, the lens supports diverse imaging systems, including fluorescence microscopy and machine vision.

6. Compact Design: 12–25 mm diameter

Its lightweight, space-saving form factor integrates seamlessly into OEM devices without sacrificing performance.

Pinhole 10mm IR corrected CCTV M12 lens

Why Thermal Stability Matters

Traditional pinhole lenses expand or contract with temperature shifts, altering the effective pinhole size and causing blurring or artifacts. Towin’s solution eliminates this issue through:

- Athermal Design: The lens assembly uses matched materials with complementary CTE values, neutralizing thermal effects.

- Precision Manufacturing: Each lens undergoes laser-assisted calibration to ensure sub-micron alignment, even after thermal cycling.

- Environmental Testing: Rigorous testing in Towin’s ISO-certified labs verifies performance under simulated conditions, from arctic cold to desert heat.

Applications Benefiting from Towin’s Innovation

1. Aerospace & Defense:

Satellites and drones rely on the lens for thermal imaging and star tracking, where temperature swings can exceed 100°C.

2. Medical Devices:

Endoscopes and confocal microscopes use the lens for sharp, artifact-free imaging during minimally invasive procedures.

3. Industrial Automation:

Machine vision systems in automotive assembly lines leverage its stability for consistent part inspection, reducing defect rates by up to 30%.

4. Scientific Research:

Laboratories studying laser-matter interactions or quantum optics depend on the lens for precise beam profiling and light control.

Pinhole-lens-30mm-IR-corrected-CCTV-M12-telecentric-lens

Towin’s Competitive Edge

Towin doesn’t just manufacture lenses—it engineers solutions. Here’s what sets the Thermally Stable Pinhole Lens apart:

- Customization: Tailor pinhole size, wavelength range, and mechanical mounting to your project’s needs.

- Rapid Prototyping: Towin’s in-house facilities deliver samples in as little as two weeks, accelerating R&D cycles.

- Global Support: With offices in Europe, Asia, and the Americas, Towin provides localized technical assistance and fast shipping.

Real-World Impact: A Case Study

A leading automotive manufacturer faced challenges with its laser welding quality control system. Temperature variations in the factory caused inconsistent pinhole performance, leading to false readings and costly rework. After switching to Towin’s Thermally Stable Pinhole Lens, the system maintained ±1% accuracy across all shifts, slashing rework costs by 22% and improving throughput by 15%.

Pinhole lens 45mm IR corrected CCTV M12 telecentric lens

Conclusion

Towin’s Thermally Stable Pinhole Lens represents a paradigm shift in optical engineering. By combining sub-micron precision with unmatched thermal resilience, it empowers industries to push the boundaries of what’s possible. Whether you’re navigating the vacuum of space or the heat of a manufacturing floor, Towin’s innovation ensures your imaging system performs flawlessly—every time.