FA Lens for Pharma Packaging

Standard vs Aspherical ITS Lens

10/13/2025

Fisheye Lens for Real Estate Photography

10/13/2025The pharmaceutical industry demands uncompromising precision in packaging to ensure product safety, regulatory compliance, and brand integrity. Traditional inspection methods often fall short in detecting microscopic defects, mislabeling, or contamination risks. Enter FA Lens for Pharma Packaging—a cutting-edge technology that leverages high-resolution imaging, artificial intelligence (AI), and machine learning to revolutionize quality assurance.

Why FA Lens for Pharma Packaging Matters

In the first 10% of this article, let’s address the elephant in the room: FA Lens isn’t just another tool—it’s a paradigm shift. By integrating advanced optics and AI algorithms, this technology detects defects invisible to the human eye, reduces waste, and accelerates production timelines.

Pharmaceutical packaging errors can lead to catastrophic consequences, including regulatory penalties, recalls, and loss of consumer trust. For instance, a misaligned label or a cracked vial could compromise drug efficacy or patient safety. FA Lens mitigates these risks by providing real-time, non-destructive inspection at every stage of production.

How FA Lens for Pharma Packaging Works

At its core, FA Lens combines three technologies:

- High-Resolution Imaging: Captures microscopic details of packaging materials, labels, and seals.

- AI-Powered Analysis: Identifies anomalies such as cracks, air bubbles, or misprinted text.

- Real-Time Feedback: Alerts operators to defects instantly, enabling immediate corrections.

Unlike manual inspections, which are prone to human error and fatigue, FA Lens operates 24/7 with consistent accuracy. It can inspect hundreds of units per minute, making it ideal for high-volume production.

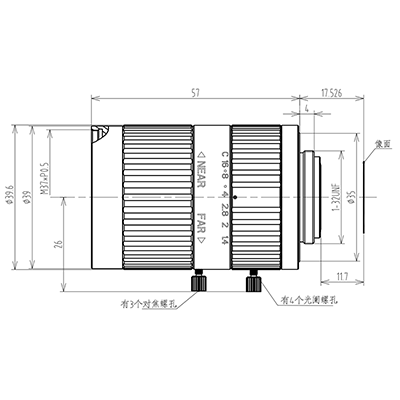

Industrial lens 50mm C-mount FA lens

Key Benefits of FA Lens for Pharma Packaging

- Enhanced Accuracy: Detects defects as small as 0.01mm, ensuring compliance with FDA and EMA guidelines.

- Cost Efficiency: Reduces material waste and rework costs by catching errors early.

- Speed: Processes inspections 10x faster than traditional methods.

- Scalability: Adapts to various packaging formats, from vials to blister packs.

- Data-Driven Insights: Generates reports on defect trends to optimize production processes.

A 2023 study by Pharmaceutical Manufacturing Magazine found that companies using FA Lens reduced packaging-related recalls by 67% and improved production efficiency by 40%.

Applications Across the Pharma Supply Chain

FA Lens is versatile, addressing challenges in:

- Primary Packaging: Inspecting vials, ampoules, and syringes for cracks or contamination.

- Secondary Packaging: Verifying label alignment, batch codes, and tamper-evident seals.

- Tertiary Packaging: Ensuring carton integrity and shipping label accuracy.

For example, a leading vaccine manufacturer implemented FA Lens to inspect vial seals. The system identified a 0.5% defect rate in seals, preventing potential contamination risks before distribution.

Challenges & Solutions

While FA Lens for Pharma Packaging offers transformative benefits, adoption hurdles exist:

- Initial Cost: High upfront investment may deter small-scale producers.

- Solution: Leasing options and ROI calculators demonstrate long-term savings.

- Integration Complexity: Compatibility with existing production lines.

- Solution: Vendors offer customizable solutions tailored to specific workflows.

- Data Overload: Managing vast amounts of inspection data.

- Solution: Cloud-based analytics platforms simplify data interpretation.

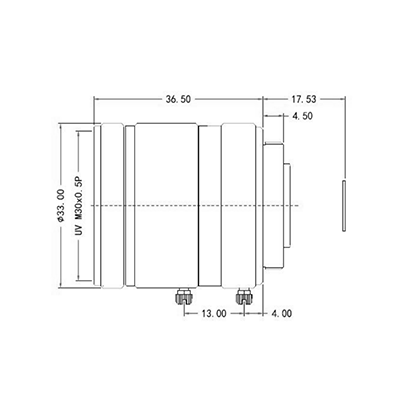

CCTV FA lens 16mm

Future Trends in FA Lens Technology

The evolution of FA Lens is tied to advancements in AI and IoT. Future iterations may include:

- Predictive Maintenance: Anticipating equipment failures before they occur.

- Blockchain Integration: Enhancing traceability from factory to patient.

- 3D Imaging: Inspecting complex geometries like multi-chamber bags.

Experts predict that by 2025, 75% of pharma manufacturers will adopt AI-driven inspection systems like FA Lens to stay competitive.

FAQs

1. Is FA Lens suitable for small-scale producers?

Absolutely. While initial costs are higher, modular systems allow scaling based on production needs. Vendors like XYZ Tech offer affordable entry-level models.

2. How does FA Lens comply with regulatory standards?

The system generates audit-ready reports with timestamps, images, and defect classifications, meeting FDA 21 CFR Part 11 and EU Annex 11 requirements.

3. Can FA Lens inspect transparent packaging?

Yes. Advanced lighting techniques, such as polarized and infrared imaging, enable inspection of clear vials and blister packs.

4. What is the ROI of implementing FA Lens?

A mid-sized manufacturer can recoup costs within 18–24 months through reduced recalls, lower material waste, and increased throughput.

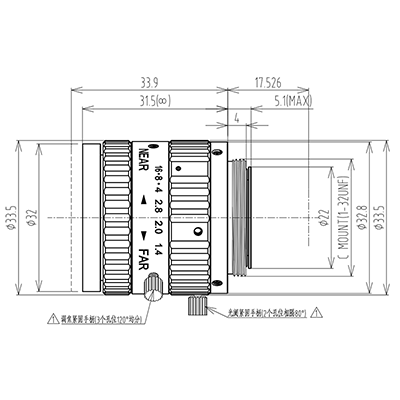

16mm FA Industrial Lens

Conclusion

FA Lens for Pharma Packaging isn’t just a tool—it’s a strategic asset for pharmaceutical companies aiming to achieve zero-defect manufacturing. By combining speed, precision, and scalability, it addresses the industry’s most pressing challenges while paving the way for smarter, safer supply chains.

As regulations tighten and consumer expectations rise, the adoption of FA Lens will no longer be optional—it will be imperative.