Low-Distortion Lenses in Machine Vision

How does a C-Mount lens work?

11/17/2025

Automotive camera lens

11/18/2025In the field of machine vision, nothing is more important than accuracy. Whether in manufacturing automation or medical imaging, the clarity and accuracy of visual data are indispensable. As the most crucial component in a machine vision system, the lens, especially a low-distortion lens, must ensure high-quality, high-precision images while minimizing optical distortion.

What is a low-distortion lens?

A low-distortion lens is an optical lens that minimizes or eliminates image distortion. Normally, lens distortion causes images to become warped, tilted, or blurred, significantly impacting the performance of various machine vision systems. Low-distortion lenses are specifically designed to generate straight lines in the image, reducing distortion. This is crucial for accurate measurement and inspection. The low-distortion characteristic is exceptionally important in applications requiring high precision in visual data.

Why are low-distortion lenses so important?

Machine vision systems typically rely on high-quality image data to interpret the environment and make optimal decisions. Low-distortion lenses reduce common optical problems such as barrel distortion and pincushion distortion. For example, when light is incorrectly bent as it passes through a lens, the image shape is magnified or compressed, resulting in distortion. These defects can severely impact the efficiency of automated systems in areas such as object detection, defect identification, and precise distance measurement. Using low-distortion lenses effectively solves these problems, improving the clarity and accuracy of visual data for manufacturers and various industries. Low-distortion lenses maintain image integrity, ensuring straight lines remain straight and objects are presented without distortion, which is crucial for applications such as quality control, robotics, and automated inspection systems.

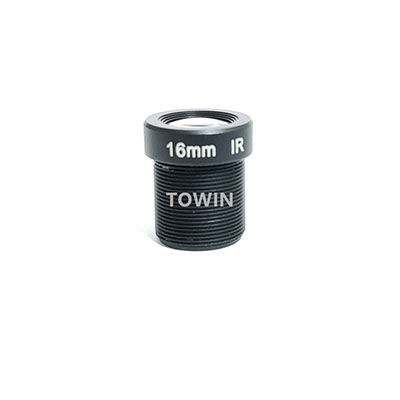

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

Key Advantages of Low-Distortion Lenses in Machine Vision

- 1. Higher Precision: Low-distortion optics enable more precise measurements and visual assessments, ensuring machine vision systems can make accurate decisions based on clear, distortion-free images.

- 2. Better Performance: By reducing image distortion, low-distortion lenses help improve the overall performance of machine vision systems, resulting in faster and more reliable operation.

- 3. Enhanced Image Quality: These lenses generate clearer, more realistic images, making it easier to identify defects, track moving objects, or create more detailed environmental maps.

- 4. Versatility: Low-distortion lenses provide consistent, high-quality visual data, making them widely applicable in a variety of machine vision applications, from industrial automation to scientific research.

- 5. Cost-Effectiveness: While low-distortion lenses have a higher upfront cost, their durability and ability to provide clearer, more accurate images can effectively reduce errors, rework, and improve system efficiency in the long run.

Applications of Low-Distortion Lenses in Machine Vision

- Quality Control and Inspection: In industries such as automotive manufacturing, electronics, and pharmaceuticals, low-distortion lenses ensure that automated inspection systems can detect minute defects or anomalies with high precision.

- Robotics: Robotic systems heavily rely on vision for interaction with the environment. Low-distortion optics enable robots to navigate and manipulate objects more effectively, avoiding errors caused by optical distortion.

- Autonomous Vehicles: Machine vision systems in autonomous vehicles require clear, distortion-free images for real-time decision-making. Low-distortion lenses enhance these systems’ ability to identify obstacles, navigate roads, and make instantaneous decisions.

- Medical Imaging: In medical imaging, especially in areas such as endoscopy or surgery, low-distortion lenses help capture clear, accurate images of internal structures, thus aiding in diagnosis and surgical planning.

- 3D Vision Systems: 3D vision systems require accurate depth perception and imaging. Low-distortion lenses ensure the geometric accuracy of captured images, which is crucial for creating reliable 3D models.

How do low-distortion lenses work?

Low-distortion lenses typically employ advanced optical materials and technologies to compensate for the distortion inherent in standard lens designs. These lenses may include aspherical surfaces to help distribute light evenly and reduce optical aberrations. Furthermore, high-quality coatings are applied to minimize light refraction and reflection, ensuring the image reproduces the real scene as faithfully as possible.

The design and manufacturing process of these lenses requires extremely high precision, as even minute deviations in lens shape or alignment can lead to distortion. High-end machine vision lens manufacturers use cutting-edge technologies such as precision grinding and polishing to create lenses that meet the stringent standards of industrial and scientific applications.

1/4″ 2mm low distortion, wide angle lens

Choosing the Right Low-Distortion Lens

- Focal Length: The focal length of a lens determines its field of view and detail capture capability. Longer focal lengths offer a narrower field of view, while shorter focal lengths capture a wider scene.

- Aperture: Aperture size affects the amount of light allowed into the lens, thus influencing image brightness and depth of field.

- Sensor Compatibility: The lens should be compatible with the camera sensors used in the machine vision system. Compatibility ensures that the lens can correctly focus light onto the sensor without introducing distortion.

- Resolution: The lens should provide sufficiently high resolution to match the performance of the camera sensor, ensuring sharp and detailed images.

FAQs

What is the difference between low-distortion lenses and regular lenses?

Regular lenses typically introduce optical distortions, such as barrel or pincushion distortion, causing straight lines to appear curved. Low-distortion lenses are specifically designed to minimize or eliminate these distortions, ensuring more accurate and realistic image reproduction.

Why is minimizing distortion so important in machine vision?

Distortion affects the accuracy and precision of machine vision systems, leading to errors in object detection, measurement, and overall system performance. Minimizing distortion ensures that the system makes reliable decisions based on clear visual data.

Can low-distortion lenses improve the performance of robotic systems?

Yes, low-distortion lenses provide clearer and more accurate images, enabling robots to better understand and interact with their environment, thereby improving navigation, manipulation, and decision-making capabilities.

Are low-distortion lenses more expensive than regular lenses?

While low-distortion lenses may have a higher initial cost, their superior performance and durability result in greater efficiency and fewer errors, making them a more cost-effective option in the long run.

25mm-Low Distortion Telecentric Lens

Conclusion

Low-distortion lenses are indispensable components of modern machine vision systems. Low-Distortion Lenses in Machine Vision ensure high-quality, high-precision images while minimizing optical distortion, which is crucial for applications requiring high precision and clarity. From manufacturing automation to medical imaging, these lenses offer better performance, higher accuracy, and superior image quality. Choosing the right low-distortion lens for your machine vision system can significantly improve the overall efficiency and performance of the system.