OEM low distortion lens

IP68 Automotive Lens

10/22/2025

Fixed focus lenses with anti-reflective coating

10/22/2025In the world of optical engineering, achieving minimal image distortion while maintaining exceptional clarity is a critical challenge. For industries ranging from machine vision to medical imaging, the demand for OEM low distortion lens has surged, driven by the need for precision and reliability. Towin, a leader in advanced optical solutions, offers cutting-edge OEM low distortion lens designed to meet stringent performance standards.

Why OEM Low Distortion Lens Matter

Distortion in lenses can severely compromise image quality, leading to inaccuracies in measurements, misaligned visuals, or flawed data analysis. An OEM low distortion lens minimizes geometric aberrations, ensuring straight lines remain straight and shapes retain their true proportions. This makes them indispensable for applications like:

- Machine Vision Systems: Automated inspection, quality control, and robotics.

- Medical Imaging: Endoscopy, microscopy, and diagnostic tools.

- Surveillance & Security: High-resolution CCTV and facial recognition.

- Augmented Reality (AR): Overlaying digital information onto real-world environments.

Towin’s OEM low distortion lenses are engineered to deliver sub-0.1% distortion rates, a benchmark that sets them apart in the market.

4mm low distortion IR Cut Filter S-Mount Lens

Technical Specifications of Towin’s OEM Low Distortion Lenses

Towin’s OEM low distortion lenses are built with precision optics and advanced materials. Key parameters include:

- 1. Focal Length: Ranges from 8mm to 50mm, catering to both wide-angle and telephoto requirements.

- 2. Aperture (F/#): Available from F1.4 to F2.8, balancing light intake and depth of field.

- 3. Distortion Rate: Less than 0.1%, ensuring minimal warping even at the edges.

- 4. Resolution: Supports resolutions up to 5 megapixels, ideal for high-detail imaging.

- 5. Coating: Multi-layer anti-reflective coatings reduce glare and enhance contrast.

- 6. Material: High-grade optical glass with low thermal expansion for stability.

- 7. Mount Type: Customizable C-mount, CS-mount, or M12 interfaces for seamless integration.

These specifications make Towin’s OEM low distortion lenses versatile for OEM partners seeking tailored solutions.

Unique Advantages of Towin’s OEM Low Distortion Lenses

- Customization Flexibility: Towin offers OEM services to adapt lenses to specific needs, including focal length adjustments, coatings, and mechanical designs.

- Cost-Effective Production: Leveraging economies of scale, Towin provides competitive pricing without compromising quality.

- Stringent Quality Control: Each lens undergoes rigorous testing for distortion, resolution, and durability.

- Global Compliance: Meets international standards such as ISO 9001 and RoHS, ensuring reliability in diverse markets.

For instance, a leading AR headset manufacturer partnered with Towin to develop a low distortion lens that reduced edge warping by 40%, enhancing user immersion.

Applications of OEM Low Distortion Lenses

- Industrial Automation: In factories, low distortion lenses enable precise defect detection on production lines.

- Aerospace & Defense: Used in drones and satellite imaging for accurate terrain mapping.

- Biometric Systems: Fingerprint and iris scanners rely on distortion-free optics for accuracy.

- Photography & Cinematography: Professional cameras use these lenses for architectural and product shots.

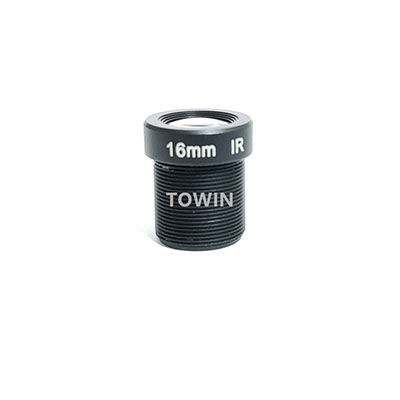

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

FAQs

1. What is the typical distortion rate of a low distortion lens?

Most high-quality OEM low distortion lenses achieve distortion rates below 0.3%, with Towin’s models pushing this below 0.1%.

2. How do low distortion lenses differ from standard lenses?

Standard lenses may exhibit 1-2% distortion, causing curved lines in images. Low distortion lenses correct this for true-to-life representation.

3. Can OEM low distortion lenses be customized for unique projects?

Absolutely. Towin specializes in OEM partnerships, offering bespoke designs for focal length, aperture, and mounting options.

4. What industries benefit most from OEM low distortion lenses?

Machine vision, medical devices, and AR/VR are primary adopters due to their reliance on precision imaging.

5. Are low distortion lenses more expensive?

While initially costlier, their ability to reduce post-processing time and errors often results in long-term savings.

6. How does Towin ensure lens quality?

Towin employs advanced metrology tools, such as interferometers, to validate distortion rates and optical performance.

Low distortion industrial 8mm fixed focus lens

Conclusion

Towin’s commitment to innovation and precision positions it as a trusted partner for OEM low distortion lens. By combining state-of-the-art manufacturing with customizable solutions, Towin empowers industries to achieve unparalleled imaging accuracy.