The Science Behind Low-Distortion Lens

Fisheye Lens Light Painting

09/28/2025

ISO-certified pinhole lens

09/28/2025The quest for flawless visuals has driven optical engineering to new heights, with low-distortion lenses emerging as a game-changer in industries from photography to aerospace. These lenses minimize aberrations—such as chromatic distortion, spherical aberration, and barrel/pincushion effects—that degrade image quality. But what exactly makes them so effective? Let’s dive into The Science Behind Low-Distortion Lens and uncover the principles, materials, and innovations driving this technological leap.

The Science Behind Low-Distortion Lens: Core Principles

At its foundation, a low-distortion lens corrects light refraction errors that occur when rays pass through curved surfaces. Traditional lenses bend light unevenly, causing straight lines to appear curved or colors to separate (chromatic aberration). Low-distortion designs tackle this through aspherical elements—non-spherical surfaces that focus light more precisely. By replacing multiple spherical lenses with one aspherical element, manufacturers reduce weight, complexity, and distortion.

Another critical factor is apochromatic correction, which aligns red, green, and blue wavelengths to a single focal point. This eliminates color fringing, a common issue in high-contrast scenes. For example, Zeiss’s Otus lenses use advanced glass coatings and precise element spacing to achieve near-zero distortion, even at wide apertures.

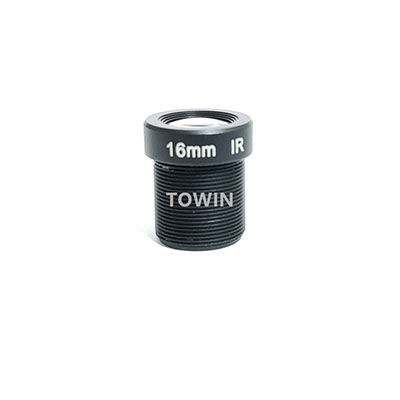

IR-corrected-Low-distortion-CCTV-16mm-M12-lens

5 Breakthroughs in Low-Distortion Technology

1. Aspherical Lens Elements

Aspherical surfaces, molded using ultra-precise diamond-turning machines, correct off-axis aberrations. Sony’s G Master series employs multiple aspherical layers to maintain edge-to-edge sharpness, a feat impossible with spherical designs alone.

2. ED (Extra-Low Dispersion) Glass

Materials like fluorite or specialized ED glass reduce chromatic aberration by bending light wavelengths uniformly. Nikon’s Nano Crystal Coat, paired with ED elements, cuts ghosting and flare by 50% compared to conventional lenses.

3. Freeform Optics

Freeform surfaces, generated by computer algorithms, enable complex curvature adjustments. This technology, used in medical endoscopes and VR headsets, achieves distortion rates below 0.1%—a 10x improvement over traditional designs.

4. Hybrid Aspherical Designs

Combining glass and plastic aspherical elements balances cost and performance. Canon’s RF lenses use molded plastic aspherics for lightweight portability, while glass aspherics handle central sharpness.

5. Computational Aberration Correction

Post-capture software, like Adobe’s Lens Correction tool, uses lens profiles to digitally remove residual distortion. However, physical lens design remains critical, as software cannot fully compensate for severe optical flaws.

Low distortion 6mm Wide angle lens

Real-World Applications

Low-distortion lenses are revolutionizing fields where precision is non-negotiable:

- Aerospace: Satellite cameras rely on distortion-free optics to map terrain accurately.

- Cinematography: ARRI’s Signature Prime lenses minimize breathing (focus-induced distortion) for seamless zoom shots.

- Microscopy: Olympus’s UPLSAPO objectives correct field curvature for high-resolution cell imaging.

Challenges and Future Directions

Despite advancements, manufacturing low-distortion lenses at scale remains costly. Aspherical elements require nanometer-level precision, driving up production costs. However, innovations like metalens technology—using flat surfaces with nanostructures to mimic curvature—could disrupt the market. Early prototypes from Harvard University show promise in achieving sub-0.01% distortion.

Conclusion

The Science Behind Low-Distortion Lens reveals a harmonious blend of physics, materials science, and engineering. From aspherical elements to computational tweaks, each innovation brings us closer to optical perfection. As demand for high-resolution imaging grows across industries, the race to eliminate distortion will only intensify—ushering in an era where “flawless” becomes the new standard.